Rigid packaging serves as a cornerstone across industries by offering durable, customizable, and regulatory-compliant solutions that protect products, optimize logistics, and elevate brand value. It encompasses diverse types such as glass, metal, plastic, paper-based materials, composites, and specialized designs to address specific industrial needs. Benefits of rigid packaging for industries include enhanced product safety, extended shelf life, efficient transportation, and sustainability, while its applications span sectors like luxury brands, electronics, cosmetics, apparel, and specialized goods. By integrating functionality with visual appeal, rigid packaging ensures product integrity, supports supply chain efficiency, and meets consumer expectations for premium experiences.

- What are the Types of Rigid Packaging for Industries?

- 1. Glass Packaging

- 2. Metal Packaging

- 3. Plastic Packaging

- 4. Paper-Based Rigid Packaging

- 5. Composite Packaging

- 6. Specialized Rigid Packaging

- What are the Benefits of Rigid Packaging for Industries?

- 1. Enhanced Product Protection

- 2. Improved Shelf Life

- 3. Optimized Transportation Efficiency

- 4. Regulatory Compliance

- 5. Elevated Brand Value and Consumer Appeal

- 6. Sustainability and Reusability

- How Does Rigid Packaging Support Industrial Supply Chains?

- What are the Applications of Rigid Packaging Across Industries?

What are the Types of Rigid Packaging for Industries?

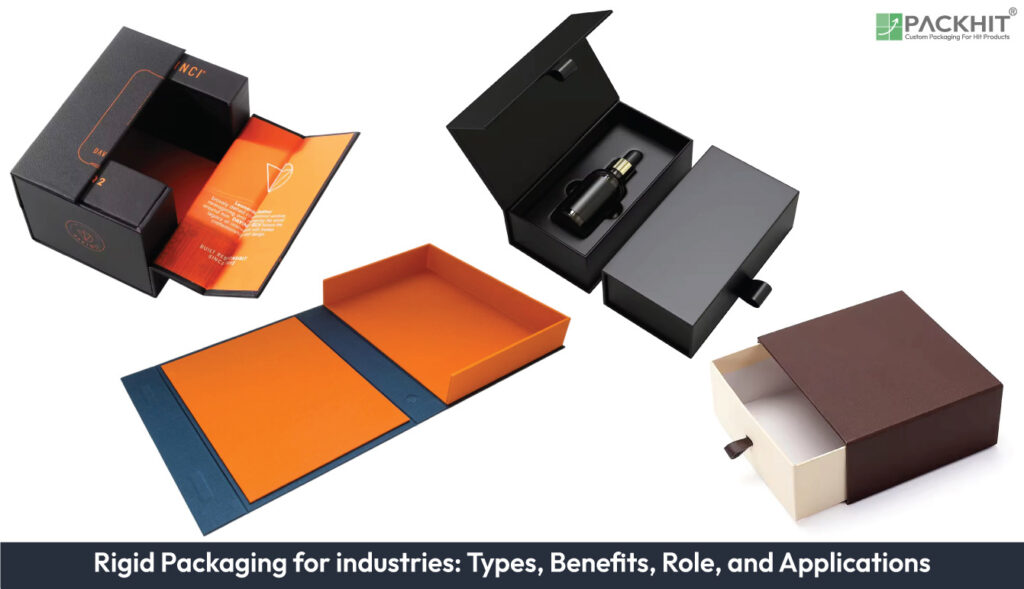

Rigid packaging encompasses a diverse range of materials and designs, each tailored to meet the specific requirements of various industries. Below, we categorize and explain the primary types of rigid packaging used across sectors:

1. Glass Packaging

Glass packaging is widely utilized for its ability to preserve product integrity and prevent contamination. Common examples include:

- Glass Bottles: Used for beverages, syrups, and liquid medications, offering airtight seals and chemical stability.

- Glass Jars: Ideal for food items such as jams, sauces, and pickles, ensuring extended shelf life.

2. Metal Packaging

Metal packaging is valued for its strength, durability, and resistance to environmental factors. Examples include:

- Metal Cans: Frequently used for canned foods, soups, and carbonated beverages, providing superior protection against external damage.

- Aluminum Containers: Lightweight and corrosion-resistant, these are utilized for pharmaceutical products and cosmetics.

3. Plastic Packaging

Plastic packaging offers versatility, cost efficiency, and lightweight solutions, making it a popular choice in multiple industries. Examples include:

- High-Density Polyethylene (HDPE) Bottles: Commonly used for liquid medications and cleaning agents due to their chemical resistance.

- Polypropylene (PP) Containers: Suitable for food storage, offering microwave-safe and reusable options.

- Thermoformed Plastic Trays: Used in electronics and pharmaceuticals for organizing and protecting products during transit.

4. Paper-Based Rigid Packaging

Paper-based rigid packaging combines sustainability with durability, offering eco-friendly solutions. Examples include:

- Corrugated Boxes: Widely used for shipping and storage, ensuring structural integrity and ease of handling.

- Rigid Cardboard Boxes: Favored by luxury brands for packaging items like perfumes, jewelry, and cosmetics.

5. Composite Packaging

Composite packaging integrates multiple materials to leverage their combined strengths. Examples include:

- Tetra Pak: A combination of paper, plastic, and aluminum, often used for dairy and beverage products.

- Blister Packs: Utilized in pharmaceuticals to individually seal tablets and capsules, ensuring hygiene and protection.

6. Specialized Rigid Packaging

Certain industries require highly customized rigid packaging solutions tailored to unique product needs. Examples include:

- Molded Foam Inserts: Used in electronics to protect sensitive components during transit.

- Luxury Packaging: Incorporates premium materials like wood or velvet for high-end products such as watches and gift sets.

Each type of rigid packaging is designed to address specific industrial challenges, whether it’s protecting delicate items, enhancing branding, or complying with regulatory standards. Selecting the right type ensures optimal performance and aligns with industry needs.

What are the Benefits of Rigid Packaging for Industries?

Rigid packaging offers a multitude of advantages tailored to meet the demands of various industries. Its unique structural and functional attributes enable manufacturers to enhance product safety, optimize logistics, and comply with regulatory standards. Below, we delve into the specific benefits:

1. Enhanced Product Protection

Rigid packaging materials, such as glass, metal, and high-grade plastics, provide unparalleled product protection. Their robust construction safeguards products against physical damage, environmental stressors, and tampering. For example, pharmaceutical companies use rigid blister packs to maintain drug integrity, while electronics manufacturers rely on molded plastic cases to shield components from electrostatic discharge.

2. Improved Shelf Life

Industries like food and beverages benefit significantly from rigid packaging’s ability to preserve freshness and prevent contamination. Airtight seals in containers such as glass jars or metal cans inhibit the growth of microorganisms, extending product shelf life and reducing waste. For instance, vacuum-sealed jars for pickles or metal cans for soups ensure long-term storage without compromising quality.

3. Optimized Transportation Efficiency

Rigid packaging facilitates efficient logistics by providing standardized shapes and sizes that are compatible with automated handling systems. Stackable designs and durable materials reduce the risk of damage during transit, allowing manufacturers to transport goods in bulk with minimal losses. This is particularly crucial in sectors like consumer goods and pharmaceuticals, where large-scale distribution is common.

4. Regulatory Compliance

Many industries are subject to stringent packaging regulations to ensure product safety and hygiene. Rigid packaging materials often meet these requirements, making them a preferred choice for sectors like pharmaceuticals and food. For instance, HDPE bottles used for liquid medications comply with FDA standards, while food-grade metal cans align with international safety protocols.

5. Elevated Brand Value and Consumer Appeal

Rigid packaging solutions are highly customizable, enabling manufacturers to design visually appealing packaging that enhances brand recognition. Features such as unique shapes, embossed logos, and vibrant printing make products stand out on shelves. Cosmetics and personal care items, like luxury glass jars for creams, often leverage this benefit to attract consumers.

6. Sustainability and Reusability

As environmental concerns grow, rigid packaging offers sustainable options, including recyclable and reusable materials. Glass containers, metal cans, and certain plastics can be recycled multiple times, reducing environmental impact. Additionally, manufacturers are increasingly adopting eco-friendly designs to align with consumer preferences for sustainable packaging.

How Does Rigid Packaging Support Industrial Supply Chains?

Rigid packaging plays a pivotal role in industrial supply chains by ensuring the safe and efficient movement of goods. Its contributions include:

- Damage Prevention: The robust construction minimizes the risk of product breakage, reducing financial losses and waste.

- Standardization: Rigid packaging solutions are often designed to meet industry standards, facilitating compatibility with automated handling and storage systems.

- Cost Efficiency: By reducing product damage and enabling bulk transportation, rigid packaging lowers overall logistics costs.

- Regulatory Compliance: Many industries, such as pharmaceuticals and food, require packaging that meets strict regulatory standards for safety and hygiene. Rigid packaging often fulfills these requirements.

What are the Applications of Rigid Packaging Across Industries?

Rigid packaging serves as a versatile solution across a wide range of industries due to its durability, functionality, and customizability. Below, we explore its applications in various sectors, with a focus on luxury brands, electronics, cosmetics, and specialized packaging needs.

1. Rigid Packaging for Luxury Brands

Luxury brands rely on rigid packaging to deliver a premium unboxing experience that reflects their brand’s exclusivity. These packaging solutions often include high-end materials, intricate designs, and fine finishes. Examples include:

- Rigid Boxes for Perfume: Rigid boxes for perfume are designed with luxurious textures, embossed logos, and magnetic closures to enhance the perceived value of the product.

- Rigid Boxes for Jewellery: Rigid boxes for jewellery are crafted with velvet linings and compartments to ensure the safety and presentation of high-value items like necklaces, rings, and watches.

- Rigid Boxes for Candles: Rigid boxes for candles often feature sturdy cardboard or wood with elegant detailing, ensuring both protection and aesthetic appeal.

2. Rigid Packaging for Electronics Products

Rigid packaging for electronics products serves as a critical solution in safeguarding sensitive components from physical damage, electrostatic discharge, and environmental factors. It is characterized by its durability, precision engineering, and ability to meet industry-specific requirements. Common examples include:

- Molded Plastic Cases: Molded plastic cases protect items like headphones, smartphones, and accessories by offering a snug fit that prevents movement during transit. Their durable construction ensures consistent protection against physical damage and environmental factors.

- Corrugated Rigid Boxes: Corrugated rigid boxes secure bulk shipments of electronics by providing structural integrity and compatibility with automated handling systems. These boxes streamline transportation processes while minimizing the risk of product damage.

- Specialized Inserts: Specialized inserts, such as foam or molded components, safeguard delicate electronics like circuit boards and chips. These inserts enhance cushioning and prevent electrostatic discharge, ensuring safe transit and storage.

- Thermoformed Plastic Trays: Thermoformed plastic trays organize and protect electronic components during transit by providing individual compartments for items like semiconductors and connectors. Their lightweight design and precision molding improve efficiency in packaging workflows.

- Anti-Static Packaging Solutions: Anti-static packaging solutions, including conductive plastic and foam materials, shield sensitive electronics from electrostatic discharge. These solutions are critical for maintaining the functionality and integrity of high-tech devices.

3. Rigid Packaging for Cosmetics and Beauty

Rigid packaging for cosmetics and beauty products merges aesthetic appeal with practical functionality, catering to industry demands for both product protection and consumer attraction. Below are key examples and applications within this sector:

- Luxury Glass Jars: Luxury glass jars used for creams and lotions, these jars feature high-grade finishes and customizable designs to enhance brand appeal.

- Rigid Boxes for Gift Sets: Rigid boxes for gift sets designed to house multiple products, such as makeup kits or skincare collections, often feature elegant prints and compartments.

- Magnetic Closure Boxes: Magnetic closure boxes are popular for high-end beauty products and provide easy access while maintaining a sleek and sturdy design.

4. Rigid Packaging for Apparel

Rigid packaging for apparel enhances branding and ensures product protection throughout transit and storage. With tailored designs and durable structures, these packaging solutions cater to both functional and aesthetic needs. Below are detailed applications in this sector:

- Luxury Apparel Boxes: Designed for high-end clothing items such as suits, dresses, or premium casual wear, these boxes feature elegant finishes, embossed logos, and reinforced corners to convey sophistication while preventing damage.

- Accessory Packaging: Accessories like ties, belts, and scarves are packaged in rigid boxes with custom inserts, ensuring they retain their shape and quality during transit. These boxes often include transparent windows for visibility and branding purposes.

- Shoe Packaging: Rigid shoe boxes utilize sturdy materials and sleek designs to protect footwear from damage and enhance the unboxing experience. High-end brands often incorporate compartments for additional items like shoe care kits.

- Gift Packaging for Apparel: Gift boxes designed for apparel items, such as themed collections or holiday sets, feature intricate designs and luxury materials to elevate the presentation. These boxes are ideal for retail displays and personal gifting.

5. Rigid Boxes for Specialized Needs

Rigid packaging is also widely used for specialized items, offering tailored solutions for unique products:

- Rigid Boxes for Cards: Rigid boxes for cards ensure secure storage for greeting cards, business cards, and collectible cards, combining durability with aesthetic appeal to enhance presentation and protection.

- Rigid Boxes for PR Packages: Rigid boxes for PR packages feature custom designs, inserts, and branding elements, allowing brands to deliver memorable experiences to influencers, media professionals, and stakeholders.

- Rigid Boxes for Gifts: Rigid boxes for gifts elevate the presentation of items for occasions such as weddings, anniversaries, and corporate events, using high-quality materials, intricate detailing, and tailored designs.

- Rigid Boxes for Subscription Boxes: Rigid boxes for subscription boxes cater to monthly deliveries of curated items, featuring durable construction and customizable branding to create a premium unboxing experience.

- Rigid Boxes for Art Supplies: Rigid boxes for art supplies protect delicate tools like brushes, paints, and sketch pads, incorporating compartments for organized storage and ease of transport.

- Rigid Boxes for Collectible Items: Rigid boxes for collectible items safeguard valuables such as coins, figurines, and limited-edition merchandise, ensuring long-term preservation and showcasing their value.

Across industries, rigid packaging continues to play a critical role in enhancing product appeal, ensuring safety, and delivering a premium experience to consumers.