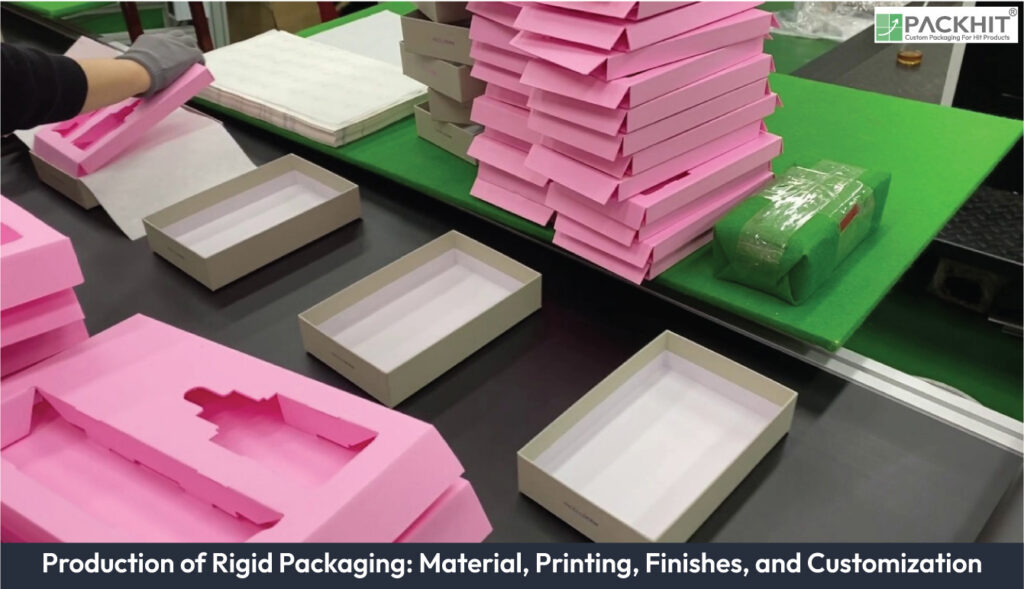

The production of rigid packaging entails a meticulous process that transforms raw materials like paperboard, plastics, metals, and corrugated fiberboard into durable and visually appealing packaging solutions. Key steps in rigid packaging production include material preparation, where substrates are refined for manufacturing; fabrication, which shapes these materials using techniques like die-cutting or injection molding; and surface treatments, such as coatings, laminations, or embossing, that enhance functionality and aesthetics. Printing techniques for rigid packaging production, ranging from offset to digital printing, ensure brand alignment and vibrant designs, while finishing methods like lamination, varnishing, and foil stamping add premium textures. Customization in Rigid packaging production plays a vital role, allowing manufacturers to tailor dimensions, branding elements, and functional features to meet specific product requirements and consumer expectations.

- What are the Key Steps in Rigid Packaging Production?

- 1. Material Preparation

- 2. Fabrication

- 3. Surface Treatment

- 4. Quality Control

- 5. Assembly and Packaging

- What Materials are Used in Rigid Packaging Production?

- How are Printing Techniques Applied in Rigid Packaging Production?

- 1. Offset Printing

- 2. Flexographic Printing

- 3. Digital Printing

- 4. Screen Printing

- 5. Gravure Printing

- 6. Hot Foil Printing

- What Types of Finishes are Used in Rigid Packaging Production?

- How is Customization Integrated into Rigid Packaging Production?

What are the Key Steps in Rigid Packaging Production?

Rigid packaging production involves a sequence of structured steps, each critical to transforming raw materials into high-quality finished products. These steps are detailed below:

1. Material Preparation

Raw materials undergo initial processing to meet specific criteria such as thickness, purity, and moisture content. For example, paperboard may require cutting to precise dimensions, while plastics are often granulated for ease of molding.

2. Fabrication

The selected manufacturing method, such as injection molding for plastics or die-cutting for paperboard, is applied to shape the material into its desired form. Fabrication methods are chosen based on the material’s properties and the intended application of the packaging.

3. Surface Treatment

Coatings, laminations, or printing are applied to enhance both the functionality and aesthetics of the packaging. For instance, UV coatings increase durability, while embossing adds a premium visual appeal. These treatments also ensure the packaging meets branding and regulatory requirements.

4. Quality Control

Products undergo rigorous testing to ensure compliance with industry standards. Tests include checks for dimensional accuracy, structural integrity, and surface quality. Advanced technologies, such as automated vision systems, are often used for consistent and precise inspections.

5. Assembly and Packaging

If necessary, components are assembled to form the final product. This step includes folding, gluing, or attaching additional elements like closures or labels. The finished items are then packaged for shipping, ensuring protection during transit.

Automation plays a pivotal role in modern production lines, streamlining processes and reducing labor costs. Robotic arms are frequently employed for material handling, assembly, and quality control tasks, ensuring consistency and improving scalability.

What Materials are Used in Rigid Packaging Production?

The materials used in rigid packaging are selected based on their mechanical strength, environmental compatibility, and suitability for various manufacturing processes. Commonly employed materials include paperboard, corrugated fiberboard, plastics, and metals, each offering distinct advantages and limitations.

Paperboard and Its Variants

Paperboard, a thick and durable paper-based material, is widely used in rigid packaging due to its lightweight nature and ease of customization. Variants such as solid bleached sulfate (SBS) and coated unbleached kraft (CUK) are frequently employed. SBS, known for its smooth surface and high printability, is ideal for premium packaging, while CUK offers superior strength and moisture resistance, making it suitable for heavier products.

Corrugated Fiberboard

Corrugated fiberboard, composed of a fluted corrugated sheet sandwiched between two flat linerboards, is valued for its high strength-to-weight ratio. It is commonly used in shipping and storage applications, where impact resistance and structural rigidity are critical. The material’s fluting profile can be adjusted to achieve varying levels of cushioning and compression strength.

Plastics

Rigid plastics, such as polyethylene terephthalate (PET), polypropylene (PP), and high-density polyethylene (HDPE), are utilized for their durability, transparency, and resistance to moisture. PET, for instance, is often used in food and beverage packaging due to its excellent barrier properties and recyclability. However, the environmental impact of plastic packaging has led to increased scrutiny and a shift toward biodegradable alternatives.

Metals

Metals, including aluminum and tinplate, are employed in rigid packaging for their exceptional strength and impermeability. Aluminum, being lightweight and corrosion-resistant, is commonly used in beverage cans and pharmaceutical containers. Tinplate, a steel sheet coated with tin, is favored for its malleability and ability to preserve perishable goods.

How are Printing Techniques Applied in Rigid Packaging Production?

Printing techniques in rigid packaging production serve to enhance visual appeal, communicate product information, and reinforce brand identity. These techniques are meticulously applied to ensure precision, durability, and alignment with design objectives. Below are the primary methods utilized:

1. Offset Printing

Offset printing is widely regarded for its ability to deliver high-quality, consistent results. It involves transferring ink from a plate to a rubber blanket and then onto the packaging surface. This method is ideal for detailed designs and vibrant color reproduction, making it a popular choice for premium paperboard packaging.

2. Flexographic Printing

Flexographic printing uses flexible plates and fast-drying inks, enabling high-speed production on various substrates, including corrugated fiberboard and plastics. Its versatility and efficiency make it suitable for large-scale operations, particularly for packaging requiring simple, bold designs.

3. Digital Printing

Digital printing allows for rapid production and customization without the need for plates. It is optimal for short-run packaging projects and designs requiring frequent updates, such as seasonal branding or promotional campaigns. This technology also supports variable data printing, enabling personalized packaging with unique identifiers like QR codes.

4. Screen Printing

Screen printing excels in applying thick ink layers, resulting in vivid and tactile designs. This technique is often used for specialty finishes, such as metallic inks or textured graphics, which are particularly effective in enhancing the perceived value of rigid packaging.

5. Gravure Printing

Gravure printing employs engraved cylinders to transfer ink, achieving exceptional detail and uniformity. It is especially suitable for high-volume production and packaging designs requiring intricate patterns or gradients. While the initial setup cost is high, the long-term efficiency offsets this expense for large-scale projects.

6. Hot Foil Printing

Hot foil printing integrates metallic foils into the packaging design using heat and pressure. This technique is frequently applied to logos, borders, and text elements, creating reflective accents that convey a premium and luxurious aesthetic.

Each printing method is selected based on the material, design complexity, and production scale. By leveraging these techniques, manufacturers can ensure that their rigid packaging not only protects the product but also delivers a compelling visual and tactile experience to consumers.

What Types of Finishes are Used in Rigid Packaging Production?

Finishes in rigid packaging enhance both the tactile and visual qualities of the product, contributing to its market appeal. Common finishing techniques include lamination, varnishing, embossing, and foil stamping.

Lamination

Lamination involves applying a thin plastic film to the surface of the packaging material, providing protection against moisture, abrasion, and UV light. Glossy and matte laminations are popular choices, with the former offering a shiny appearance and the latter a subdued, elegant look.

Varnishing

Varnishing is a cost-effective alternative to lamination, involving the application of a liquid coating that dries to form a protective layer. Spot varnishing, where the varnish is applied selectively, is often used to highlight specific design elements.

Embossing and Debossing

Embossing creates raised patterns on the packaging surface, while debossing results in recessed designs. These techniques add a tactile dimension to the packaging, enhancing its perceived value and brand identity.

Foil Stamping

Foil stamping involves the application of metallic or pigmented foil to the packaging surface using heat and pressure. This technique is commonly used to create reflective accents, such as logos and borders, that convey a sense of luxury.

How is Customization Integrated into Rigid Packaging Production?

Customization is a pivotal aspect of rigid packaging production, enabling manufacturers to create packaging solutions that align precisely with product specifications, brand identity, and consumer expectations. It involves a combination of structural adjustments, aesthetic enhancements, and functional integrations.

Tailored Dimensions

Custom dimensions ensure that the packaging fits the product securely, minimizing movement during transit and reducing the risk of damage. This is particularly important for fragile or high-value items.

Branding Elements

Branding elements, such as logos, color schemes, and typography, are incorporated into the packaging design to reinforce brand identity and enhance consumer recognition. Advanced printing and finishing techniques enable the precise reproduction of these elements.

Functional Features

Functional features, such as handles, windows, and compartments, are integrated into the packaging to improve usability and consumer experience. For instance, die-cut windows allow consumers to view the product without opening the package, while compartments facilitate the organization of multiple items.