The packaging design process is a structured methodology aimed at creating effective, visually appealing, and functional packaging for products. It follows an eight-step workflow that begins with analyzing the design brief and establishing timelines and budgets. The process continues with research, concept development, and artwork refinement, followed by prepress production, testing for durability and usability, and finalization for mass production. Its core purpose is to create functional, market-ready packaging aligned with brand goals. Common challenges in the packaging design process include delayed decisions, material selection issues, and excessive revisions, which can be managed through clear planning and communication.

- What is the Packaging Design Process?

- 1. Understanding the Design Brief

- 2. Establishing a Project Plan

- 3. Research and Discovery

- 4. Concept Development

- 5. Artwork Implementation and Review

- 6. Prepress Production

- 7. Testing

- 8. Finalization

- Which Design Software is Used in the Packaging Design Process?

- What is the Core Purpose of the Packaging Design Process?

- What are the Common Challenges in the Packaging Design Process?

What is the Packaging Design Process?

The packaging design process is a comprehensive, multi-stage workflow that begins with unpacking the brief, analyzing client requirements to identify missing elements, and clarifying expectations. This is followed by establishing a project plan with defined timelines, budgets, and deliverables to ensure accountability. Next comes research and discovery, where consumer insights, market trends, and competitor strategies are examined to guide differentiation. Concept development follows, involving brainstorming, sketching, and exploring visual and structural ideas. Once a concept is selected, artwork is implemented and refined to align with the brand identity. The design then enters prepress production, where dielines, color targets, and special finishes are finalized for print readiness. Rigorous testing is conducted to validate durability, functionality, and consumer usability, allowing for necessary adjustments. Finally, the process concludes with design finalization, where all specifications are confirmed, compliance is ensured, and the packaging is prepared for mass production, aligning with brand goals and consumer expectations.

The packaging design process involves eight key steps, which are mentioned below:

1. Understanding the Design Brief

The process begins with a thorough analysis of the packaging design brief. This document outlines the project’s objectives, target audience, budget, and any specific requirements. Designers evaluate the brief to identify any gaps or ambiguities and ensure all stakeholders are aligned on the project’s goals.

2. Establishing a Project Plan

A detailed project plan is created to ensure accountability in terms of timing, budget, and quality. This step involves setting clear milestones and deliverables to keep the process on track.

3. Research and Discovery

Research is conducted to gather insights into consumer preferences, market trends, and competitor strategies. This step is especially beneficial for brands with limited media and advertising support, as it helps identify opportunities to differentiate their packaging.

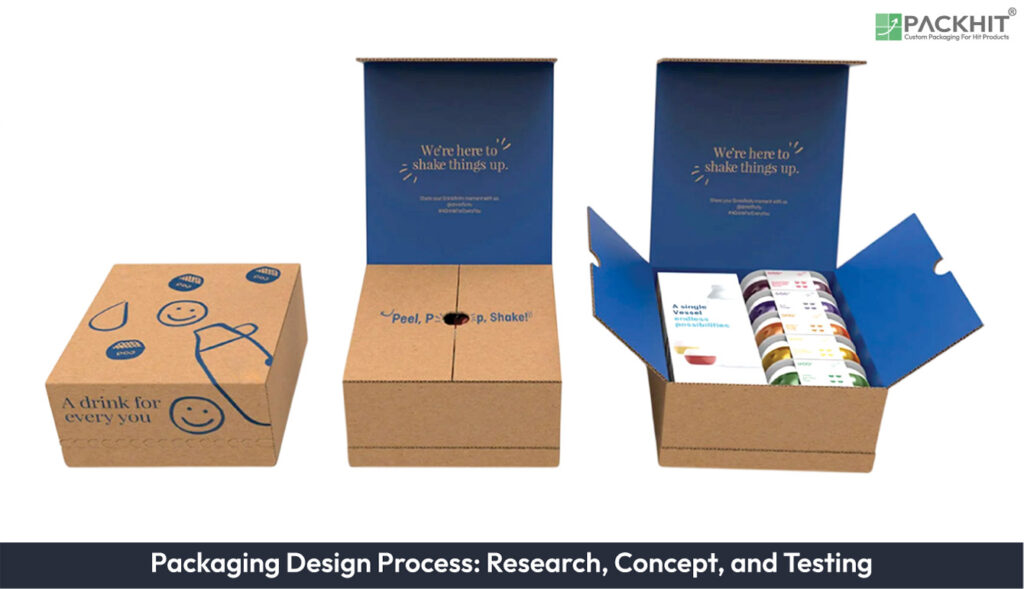

4. Concept Development

Designers create initial concepts based on the insights gathered during the research phase. This step involves brainstorming ideas, sketching designs, and exploring different visual and structural options.

5. Artwork Implementation and Review

Once a concept is finalized, the packaging artwork design is developed and reviewed. This includes creating detailed graphics, selecting colors, and ensuring the design aligns with the brand’s identity. Revisions are made as needed to refine the design.

6. Prepress Production

In this stage, the design is prepared for printing. This involves creating dieline templates, setting color targets, and ensuring the design is print-ready. Special finishes, such as embossing or foil stamping, are also planned and discussed with suppliers.

7. Testing

Testing is a critical phase in the packaging design process where prototypes are evaluated to ensure they meet quality standards and perform effectively under real-world conditions. Packaging design testing involves assessing durability, functionality, and consumer usability through rigorous trials and feedback loops. Testing also helps identify potential issues such as structural weaknesses or material incompatibilities, allowing for adjustments before the design is finalized.

8. Finalization

Finalization is the concluding step in the packaging design process, where adjustments based on testing results are implemented to optimize the design for production. This stage includes confirming all specifications, ensuring compliance with industry standards, and finalizing details like printing techniques and special finishes. Once approved, the design is prepared for mass production, ensuring it aligns with the brand’s vision and meets consumer expectations.

Which Design Software is Used in the Packaging Design Process?

Design software plays a critical role in the packaging design process, enabling designers to create precise, professional, and print-ready artwork. Commonly used tools include:

- Adobe Illustrator: Ideal for creating vector-based designs, logos, and dielines.

- Adobe Photoshop: Used for image editing and creating detailed mockups.

- Esko Studio: Specialized for 3D packaging visualization and structural design.

- CorelDRAW: A versatile tool for vector graphics and layout designs.

- ArtiosCAD: Focused on structural packaging design, especially for creating dielines and prototypes.

These packaging design tools enable designers to streamline workflows, maintain precision, and ensure compatibility with printing and production processes.

What is the Core Purpose of the Packaging Design Process?

The primary purpose of the packaging design process is to create packaging that meets quality, budget, and timing requirements while enhancing the product’s marketability. It serves as a guide for designers, brand managers, and manufacturers to ensure that every aspect of the packaging aligns with the product’s goals and consumer expectations.

What are the Common Challenges in the Packaging Design Process?

The packaging design process, while essential for creating effective and consumer-centric packaging, comes with its own set of challenges. These hurdles can impact timelines, budget, and final outcomes if not addressed effectively. Key challenges include:

- Late Decision-Making: Delays in critical decisions during the process can lead to rushed outcomes, compromising quality and functionality.

- Material Selection: Striking a balance between cost, sustainability, and functionality often makes choosing the right materials a complex task.

- Iterative Revisions: While necessary for refinement, excessive revisions can inflate costs and extend production timelines if not managed efficiently.

By proactively addressing these issues through clear communication, strategic planning, and stakeholder alignment, manufacturers can streamline the process and achieve optimal results for their packaging designs.