Child-resistant Mylar bags are specialized packaging solutions designed to ensure product safety and compliance across industries like pharmaceuticals, cannabis, and household chemicals. Constructed with durable Mylar material, these bags incorporate certified child-resistant closures, such as press-to-close zippers and sliding locks, to prevent unauthorized access by children while remaining functional for adults. Their multilayered barrier films provide excellent protection against moisture, oxygen, and UV light, preserving product integrity over time. Additional features include odor containment through aluminum layers, customizable designs for branding and size requirements, and temperature resistance ranging from -80°C to 150°C, making them suitable for refrigeration and sterilization. These properties enable long-term durability and secure storage, while their flexibility, cost-effectiveness, and environmental considerations distinguish them from alternative packaging solutions. Manufacturers must adhere to rigorous regulatory standards, including ASTM D3475 testing protocols and state-specific labeling requirements, to ensure compliance and consumer safety.

- What are Child-Resistant Mylar Bags?

- What are the Key Features of Child-Resistant Mylar Bags?

- Child-Resistant Closures

- Multilayered Barrier Films

- Durability

- Odor Containment

- Customizable Design

- Temperature Resistance

- How Do Child-Resistant Mechanisms in Mylar Bags Work?

- What are the Storage Capabilities of Child-Resistant Mylar Bags?

- What are the Primary Uses of Child-Resistant Mylar Bags?

- How Do Child-Resistant Mylar Bags Compare to Alternative Packaging?

- What are the Regulatory Considerations for Manufacturers?

What are Child-Resistant Mylar Bags?

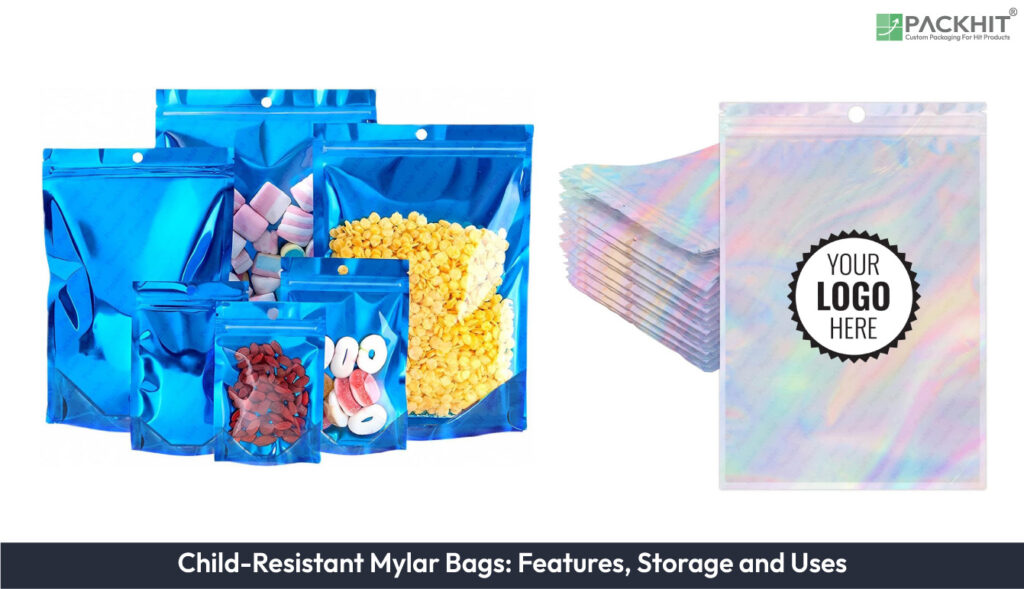

Child-resistant Mylar bags are specialized packaging solutions designed to protect sensitive products while preventing unauthorized access by children. Their construction combines durable Mylar material, a biaxially oriented polyethylene terephthalate (BoPET) film, with certified child-resistant mechanisms such as press-to-close zippers or sliding locks. Child-resistant Mylar bags are widely used for storing items like pharmaceuticals, cannabis, household chemicals, and other products requiring both safety and environmental protection.

What are the Key Features of Child-Resistant Mylar Bags?

Child-resistant Mylar bags incorporate several specialized features that ensure safety, durability, and product preservation. These features are integral to their widespread use in industries requiring secure packaging for sensitive items. Key attributes include:

Child-Resistant Closures

These bags are equipped with specialized mechanisms, such as press-to-close zippers, sliding locks, or push-and-turn caps, that meet stringent safety standards. These closures prevent access by children while remaining functional for adults.

Multilayered Barrier Films

The construction of child-resistant Mylar bags utilizes durable materials, including biaxially oriented polyethylene terephthalate (BoPET). This ensures excellent resistance to moisture, oxygen, and UV light, preserving product integrity over extended periods.

Durability

Child-resistant Mylar bags are designed to withstand punctures, tears, and environmental stress. This durability ensures that the bags maintain their physical integrity even under challenging storage conditions.

Odor Containment

Many of these Mylar bags feature an aluminum foil layer that effectively traps odors. This makes them particularly suitable for storing products like cannabis or chemicals with strong scents.

Customizable Design

Manufacturers can customize the size, shape, and branding of these bags to meet specific product requirements. This ensures enhanced user experience while maintaining compliance with safety regulations.

Temperature Resistance

Child-resistant Mylar bags can handle a wide temperature range, from -80°C to 150°C. This versatility allows for applications such as refrigeration or high-temperature sterilization processes.

By integrating these features, child-resistant Mylar bags offer a secure and versatile packaging solution for manufacturers across various industries, ensuring both product safety and compliance with regulatory standards.

How Do Child-Resistant Mechanisms in Mylar Bags Work?

The child-resistant functionality of these bags is achieved through mechanical closures that require a combination of dexterity and strength to open, which are typically beyond the capabilities of young children. Common mechanisms include:

- Press-to-Close Zippers: These zippers require precise alignment and simultaneous pressure to open, making them difficult for children to manipulate.

- Push-and-Turn Caps: Often used in conjunction with Mylar pouches, these caps require a coordinated push-and-twist motion to unlock.

- Sliding Locks: These mechanisms involve a sliding component that must be moved in a specific direction while applying pressure, adding an additional layer of complexity.

These closures are rigorously tested under CPSC protocols, which involve trials with children aged 42 to 51 months to ensure compliance with safety standards.

What are the Storage Capabilities of Child-Resistant Mylar Bags?

Child-resistant Mylar bags are engineered to provide optimal storage conditions for a wide range of products. Their storage capabilities are defined by the following attributes:

- Barrier Properties: The multilayered Mylar film effectively blocks moisture, oxygen, and UV light, preserving the freshness and potency of stored products. Oxygen transmission rates (OTR) and moisture vapor transmission rates (MVTR) are typically below 0.1 cc/m²/day and 0.1 g/m²/day, respectively.

- Temperature Resistance: Mylar bags can withstand a broad temperature range, from -80°C to 150°C, making them suitable for both refrigeration and high-temperature sterilization processes.

- Odor Containment: The aluminum layer in many Mylar bags prevents the escape of strong odors, a critical feature for products like cannabis or certain chemicals.

- Long-Term Durability: Mylar’s resistance to punctures and tears ensures that the bags maintain their integrity over extended storage periods, even under challenging conditions.

What are the Primary Uses of Child-Resistant Mylar Bags?

Child-resistant Mylar bags are utilized across various industries where secure and protective packaging is essential. Key applications include:

Pharmaceuticals

Child-resistant Mylar bags are essential for storing prescription medications, over-the-counter drugs, and dietary supplements. These bags ensure compliance with child safety regulations while protecting contents from exposure to moisture, oxygen, and light, which can degrade their efficacy.

Cannabis Products

In the cannabis industry, regulations mandate child-resistant Mylar bags for packaging edibles, concentrates, and dried flower. These bags prevent accidental ingestion by children and maintain the product’s potency by providing excellent barrier protection against air, light, and odors.

Household Chemicals

Products such as detergents, cleaning agents, and pesticides are often packaged in child-resistant Mylar bags. These bags minimize the risk of accidental exposure by employing certified child-resistant closures while preserving the chemical stability of the contents.

Food and Beverages

Although less common, child-resistant Mylar bags are sometimes used for premium or sensitive food items, such as specialty coffee, teas, or freeze-dried meals. The bags protect against environmental factors like humidity and UV light while incorporating safety mechanisms to prevent access by children.

How Do Child-Resistant Mylar Bags Compare to Alternative Packaging?

Compared to other child-resistant packaging options, such as rigid plastic containers or blister packs, Mylar bags offer several advantages:

- Flexibility: Mylar bags are lightweight and flexible, reducing shipping and storage costs compared to rigid containers.

- Customizability: The ability to print directly on the bag surface allows for high-quality branding and labeling, which is more challenging with rigid packaging.

- Environmental Impact: Many Mylar bags are recyclable or made from partially recycled materials, offering a more sustainable option than single-use plastics.

- Cost-Effectiveness: Mylar bags are generally more affordable to produce in bulk, making them a cost-efficient choice for manufacturers.

What are the Regulatory Considerations for Manufacturers?

Manufacturers of child-resistant Mylar bags must adhere to stringent regulatory requirements to ensure product safety and market compliance. Key considerations include:

- Testing Protocols: Compliance with ASTM D3475 standards and CPSC guidelines is mandatory. This involves child panel testing to verify the effectiveness of the child-resistant mechanisms.

- Labeling Requirements: Packaging must include clear instructions for opening and warnings to keep the product out of reach of children.

- State-Specific Regulations: In the United States, cannabis packaging laws vary by state, requiring manufacturers to tailor their products to meet local requirements.

- Material Safety: The materials used in the bags must be food-grade and free from harmful chemicals, such as BPA or phthalates, to ensure consumer safety.

By meeting these regulatory standards, manufacturers can ensure that their child-resistant Mylar bags are both effective and legally compliant, providing a reliable packaging solution for sensitive products.