Electronics Mylar bags are specialized multilayer packaging solutions designed to protect sensitive electronic components from environmental threats and electrostatic discharge (ESD). These bags typically consist of layers such as PET for mechanical strength, aluminum for moisture and oxygen barriers, anti-static coatings for ESD protection, and polyethylene for sealing flexibility. They prevent ESD through surface resistivity control, the Faraday cage effect, and conductive pathways that safely dissipate static charges. Safety features include high durability, chemical resistance, tamper-evident seals, and compliance with industry standards like MIL-PRF-81705. Additionally, these bags shield components from humidity, oxygen exposure, UV light, and temperature fluctuations, ensuring long-term reliability and performance.

What Are Electronics Mylar Bags?

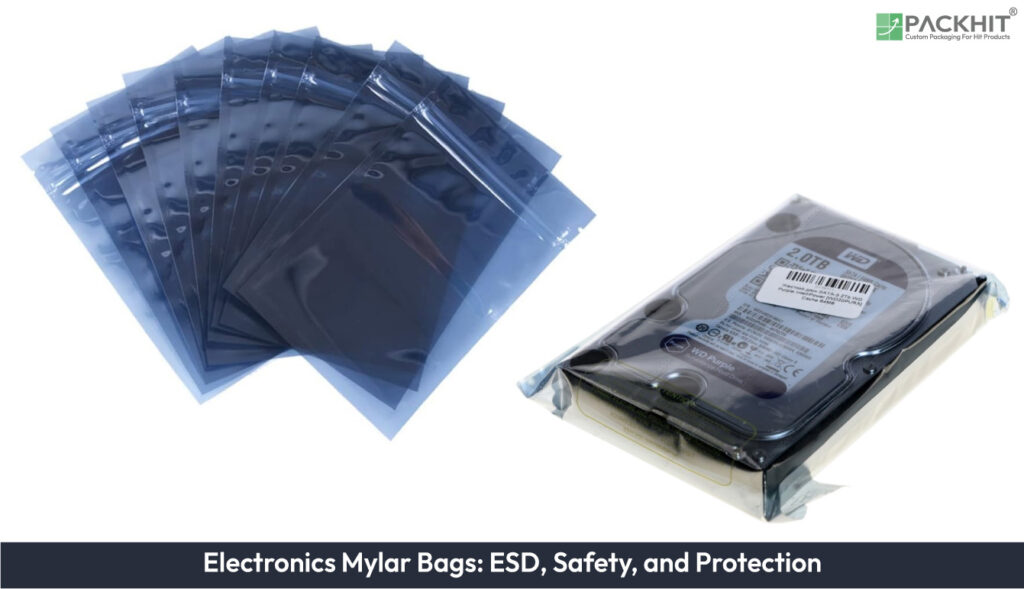

Electronics Mylar bags are advanced packaging solutions specifically designed to protect sensitive electronic components from environmental threats and electrostatic discharge (ESD). These bags are constructed using a multilayered design that incorporates polyethylene terephthalate (PET), metallic coatings such as aluminum, and anti-static layers. This combination ensures robust protection against moisture, oxygen, light exposure, and physical damage, while also minimizing risks associated with static electricity.

The unique material composition of Electronics Mylar bags allows them to offer high barrier properties and mechanical strength, making them indispensable for the safe storage and transportation of electronic devices. With their ability to meet stringent industry standards for ESD protection and environmental resistance, these bags play a critical role in maintaining the functionality and longevity of electronic components..

What Functions Do the Material Layers of Electronics Mylar Bags Serve?

The material layers of Electronics Mylar bags serve distinct purposes: the PET layer provides mechanical strength and chemical resistance, the aluminum coating ensures a moisture and oxygen barrier, the anti-static coating protects against electrostatic discharge, and the polyethylene layer enhances flexibility and sealing efficiency.

- PET Layer: Offers mechanical strength and chemical resistance, ensuring the bag maintains its structural integrity and protects against chemical interactions.

- Aluminum Coating: Acts as a robust barrier, preventing moisture, oxygen, and light from penetrating and compromising the contents.

- Anti-Static Coating: Dissipates electrostatic charges, reducing the risk of damage to sensitive electronic components caused by electrostatic discharge (ESD).

- Polyethylene Layer: Improves flexibility and creates effective seals, ensuring the bag securely encloses its contents during storage and transportation.

How Do Electronics Mylar Bags Prevent Electrostatic Discharge (ESD)?

Electronics Mylar bags employ specific mechanisms to protect sensitive electronic components from electrostatic discharge (ESD), a major concern that can cause irreparable damage to devices. Below are the subheadings detailing how these bags mitigate ESD risks:

1. Surface Resistivity Control

The anti-static coatings applied to Electronics Mylar bags maintain a surface resistivity within the range of 105 to 1011 ohms per square. This ensures uniform dissipation of static charges across the bag’s surface, preventing localized buildup that could harm delicate components.

2. Faraday Cage Effect

The metallic layer within the bag acts as a Faraday cage, effectively blocking external electrostatic fields and shielding the contents from potential ESD hazards. This feature is particularly crucial during handling and transportation in environments prone to static generation.

3. Conductive Pathways

The conductive or semi-conductive materials used in the anti-static coatings create pathways that facilitate the dissipation of static charges. This prevents charge accumulation on the bag’s surface, ensuring safe storage and handling of electronic components.

What Safety Features Do Electronics Mylar Bags Offer?

Electronics Mylar bags incorporate advanced safety features to ensure the protection of sensitive components during storage and transportation. These features extend beyond electrostatic discharge (ESD) safeguards, emphasizing physical durability, chemical resistance, and adherence to rigorous industry standards.

The safety features of the electronics mylar bags are given below:

Physical Durability

The robust polyethylene terephthalate (PET) layer provides exceptional mechanical strength, resisting punctures, tears, and abrasions. This durability ensures the bag maintains its structural integrity even under challenging conditions, protecting the enclosed components from physical damage.

Chemical Resistance

The aluminum coating within Electronics Mylar bags acts as an effective barrier against moisture, oxygen, and other corrosive agents. This layer prevents contamination and oxidation, which can compromise the functionality and longevity of electronic components.

Tamper-Evident Seals

Heat-sealable properties enable the creation of secure, tamper-evident closures. These seals provide an additional layer of safety, ensuring that the contents remain intact and undisturbed during handling and transportation.

Compliance with Industry Standards

Electronics Mylar bags are manufactured to meet stringent industry benchmarks. Examples include MIL-PRF-81705 for ESD protection and ASTM D882 for tensile strength. These certifications validate the reliability and safety of the bags in demanding applications across various industries.

How Do Electronics Mylar Bags Protect Against Environmental Hazards?

Electronics Mylar bags safeguard against environmental hazards through multiple protective mechanisms, as discussed below:

Protection Against Humidity

Electronics Mylar bags provide an effective barrier against moisture. The aluminum coating prevents water vapor ingress, ensuring that electronic components remain dry and free from humidity-related damage.

Shielding from Oxygen Exposure

The aluminum layer also blocks oxygen, preventing oxidative reactions that could degrade sensitive components. This protection is critical for maintaining the performance and longevity of electronic devices.

UV Light Protection

The opaque metallic layer of the bags prevents ultraviolet (UV) light from penetrating, reducing the risk of photodegradation in components that are sensitive to light exposure.

Temperature Stability

The polyethylene terephthalate (PET) layer provides excellent structural integrity, allowing the bags to withstand temperature variations without degrading. This ensures consistent protection across fluctuating environmental conditions.