Shoulder neck rigid box represents a specialized type of packaging known for its dual-layered design combining an elevated “shoulder” platform and a recessed “neck” cavity. Manufactured using rigid materials like chipboard or cardboard, these boxes seamlessly blend durable protection with aesthetic sophistication. They cater to diverse industries, including luxury goods, electronics, cosmetics, food, and specialty products, providing tailored solutions for premium packaging needs. Key benefits include enhanced product security, versatile branding opportunities through advanced customization techniques like embossing and foil stamping, and a premium unboxing experience that strengthens consumer perception and loyalty. Furthermore, their eco-friendly and reusable design aligns with sustainability goals, while practical features such as stackability and secure closures optimize storage and product handling. Manufacturers can further customize these boxes with functional elements like magnetic closures, ribbon pulls, or die-cut windows, ensuring that packaging not only protects but also enhances the overall user experience.

- What is a Shoulder Neck Rigid Box?

- What Are the Common Uses of Shoulder Neck Rigid Boxes?

- What are the Benefits of Shoulder Neck Rigid Boxes?

- 1. Enhanced Product Protection

- 2. Versatile Branding Opportunities

- 3. Premium Consumer Experience

- 4. Eco-Friendly and Reusable Design

- 5. Practicality for Storage and Organization

- How Can Manufacturers Customize Shoulder Neck Rigid Boxes?

What is a Shoulder Neck Rigid Box?

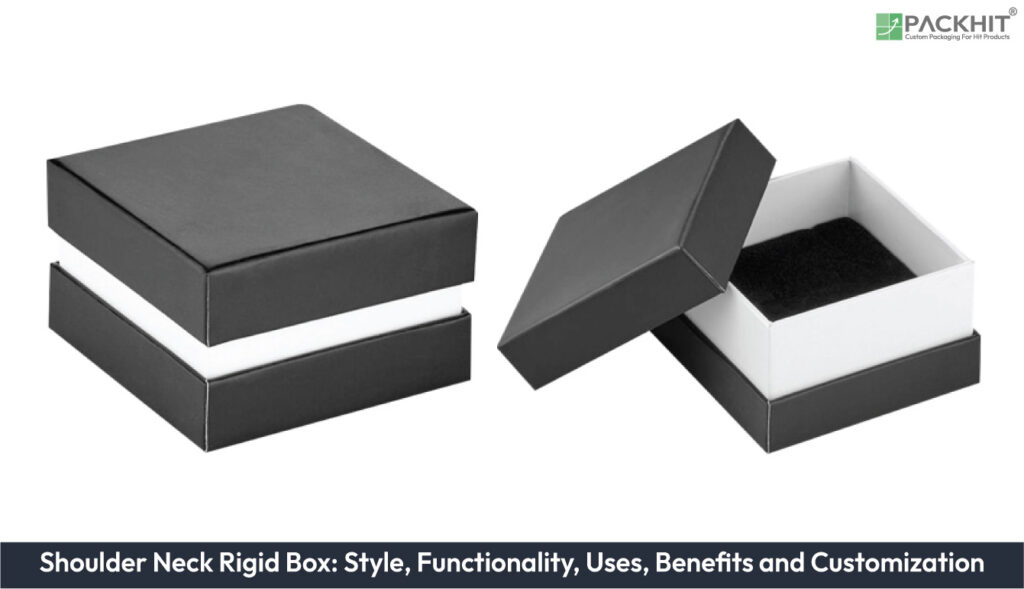

A shoulder neck rigid box is defined by its unique structural design, which incorporates two distinct components: the shoulder and the neck. The shoulder is an elevated section that supports the lid, while the neck is a recessed area that creates a snug fit for the base and lid. This dual-layered design not only enhances the box’s visual appeal but also improves its functional performance by ensuring a secure closure and added durability. Typically constructed from rigid materials such as chipboard or cardboard, these boxes are covered with decorative paper or fabric to achieve a refined finish.

What are the Core Properties of Shoulder Neck Rigid Boxes?

The core properties of shoulder neck rigid boxes are as follows:

- Structural Integrity: Designed with rigid materials such as chipboard or cardboard, these boxes resist deformation, ensuring long-term durability and protection for enclosed products.

- Material Composition: Constructed from high-quality rigid components, they provide a sturdy framework suitable for premium packaging needs.

- Design Versatility: The dual-layered shoulder and neck design contribute to the box’s stability and seamless fit between the lid and base.

- Aesthetic Appeal: External covering materials, including textured paper or laminated finishes, enhance branding potential and overall visual presentation.

What Are the Common Uses of Shoulder Neck Rigid Boxes?

Shoulder neck rigid boxes are employed across multiple industries due to their aesthetic appeal, structural reliability, and branding potential. The following sectors most commonly utilize these boxes:

1. Luxury Goods

In the luxury goods sector, shoulder neck rigid boxes are used to package premium items such as watches, jewelry, and perfumes. Their elegant design enhances product presentation, aligning with the exclusivity associated with high-end goods.

2. Electronics

Electronics manufacturers rely on these boxes to house high-end gadgets, such as smartphones and accessories. The sturdy construction provides protection against damage, while the refined appearance complements the premium nature of the products.

3. Cosmetics

Cosmetics brands leverage the aesthetic and customizable features of shoulder neck rigid boxes for items like skincare sets and makeup kits. These boxes emphasize elegance and brand identity, making them ideal for retail and gifting purposes.

4. Food and Beverages

In the food and beverage industry, these boxes are used for packaging gourmet items such as chocolates, specialty teas, and artisanal products. Their ability to maintain product integrity while offering a premium unboxing experience makes them a preferred choice.

5. Specialty Products

Beyond the aforementioned industries, shoulder neck rigid boxes are increasingly utilized for niche sectors like collectibles, gift sets, and promotional items. Their adaptable design accommodates unique packaging requirements while maintaining visual appeal.

What are the Benefits of Shoulder Neck Rigid Boxes?

Shoulder neck rigid boxes provide diverse advantages for manufacturers and consumers, blending aesthetic appeal with practical functionality. Below, these benefits are categorized for clarity:

1. Enhanced Product Protection

Shoulder neck rigid boxes are engineered with rigid materials like chipboard and cardboard, ensuring robust construction that mitigates risks of physical damage. The dual-layered design—comprising the elevated shoulder and recessed neck—creates a secure enclosure, safeguarding fragile, high-value items during transit and storage. This structural integrity is particularly vital for industries dealing with delicate goods, such as electronics or luxury cosmetics.

2. Versatile Branding Opportunities

These boxes serve as a dynamic branding platform, enabling manufacturers to integrate visually impactful elements like logos, custom color palettes, and thematic designs. Advanced customization techniques, including embossing, foil stamping, and UV printing, further enhance brand visibility and differentiation. Whether packaging premium jewelry or high-end electronics, the ability to align design with brand identity helps products stand out in competitive markets.

3. Premium Consumer Experience

The luxurious unboxing experience offered by shoulder neck rigid boxes elevates perceived product value. Features such as magnetic closures and ribbon pulls add both functionality and sophistication, fostering a sense of exclusivity. This tactile and visual appeal is essential for brands aiming to strengthen consumer trust and loyalty, especially in sectors like luxury goods and gourmet food packaging.

4. Eco-Friendly and Reusable Design

Manufactured with durable materials, these boxes align with sustainability goals by promoting reuse and reducing packaging waste. Their sturdy construction makes them ideal for repurposing, whether for storage or creative applications, contributing to eco-conscious branding strategies. This sustainable edge resonates particularly well with environmentally aware consumers and businesses.

5. Practicality for Storage and Organization

Shoulder neck rigid boxes excel in practicality, offering stackable designs that simplify storage and retail display arrangements. The snug fit between the lid and base minimizes accidental openings, preserving product integrity. This organized, secure packaging solution is crucial for industries requiring efficient handling and presentation, such as cosmetics or electronics.

How Can Manufacturers Customize Shoulder Neck Rigid Boxes?

Manufacturers can customize shoulder neck rigid boxes through a variety of design and material options. Customization begins with selecting the box dimensions and structural features to suit the specific product requirements. Decorative elements such as embossing, foil stamping, and UV printing can be added to enhance branding and visual appeal. Internal compartments can be designed to securely hold multiple items, while external finishes can range from matte to glossy, depending on the desired aesthetic. Additionally, manufacturers can incorporate functional features such as magnetic closures, ribbon pulls, or die-cut windows to improve usability and consumer engagement.