Mushroom packaging, a biodegradable and eco-friendly alternative to traditional packaging materials, is composed of agricultural waste bound together by mycelium, the root structure of mushrooms. This innovative material offers complete biodegradability, minimal energy consumption during production, and sufficient durability for protecting fragile items. Its applications span industries such as electronics, consumer goods, and logistics, where sustainable packaging is increasingly prioritized. By leveraging natural decomposition processes, mushroom packaging reduces environmental impact while enriching soil with nutrients, positioning it as a critical component in the transition to sustainable manufacturing practices.

What is Mushroom Packaging?

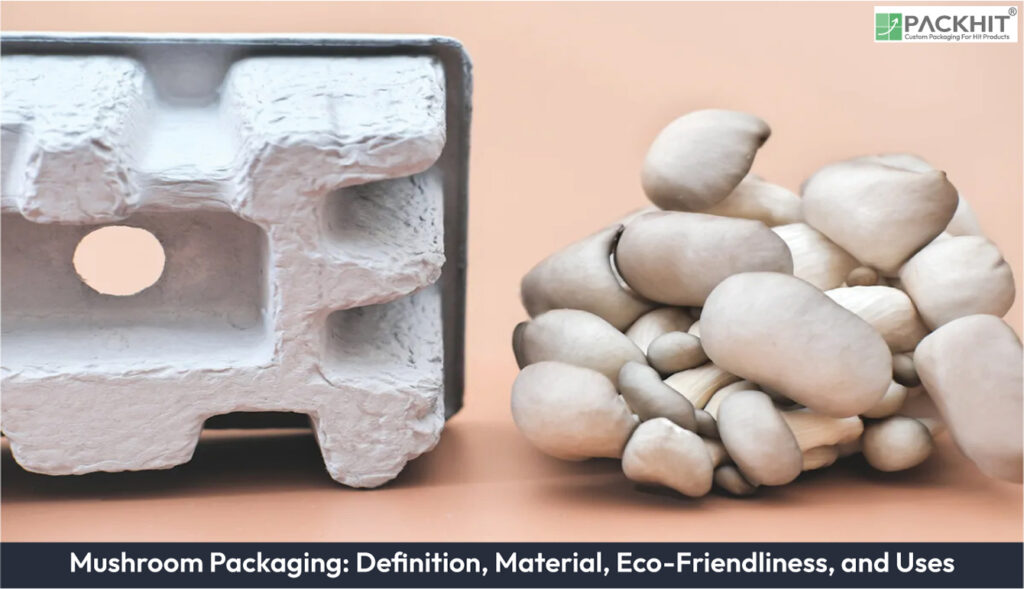

Mushroom packaging is an eco-friendly packaging material made from agricultural waste and mycelium, the root structure of mushrooms. It serves as a sustainable alternative to synthetic materials like polystyrene, offering complete biodegradability and minimal environmental impact. This innovative material is durable enough to protect fragile items while being fully compostable, making it an ideal choice for industries aiming to reduce their ecological footprint.

What Material is Mushroom Packaging made of?

Mushroom packaging is primarily composed of two materials, which include agricultural waste, such as corn husks or hemp stalks, and mycelium. Mycelium acts as a natural adhesive, binding the agricultural byproducts into a solid structure. This composition ensures the material is entirely biodegradable and free from synthetic additives.

How is Mushroom Packaging Manufactured?

The manufacturing process of mushroom packaging begins with the preparation of agricultural waste, such as corn husks or hemp stalks, which is cleaned and sterilized to eliminate contaminants. Mycelium, the root structure of mushrooms, is then introduced to the substrate, where it grows and binds the particles together over several days. The material is molded into specific shapes during this growth phase, after which it is heat-treated to halt further fungal growth and solidify the structure. This low-energy process contrasts sharply with the resource-intensive production of plastics and polystyrene.

What Makes Mushroom Packaging Eco-Friendly?

Mushroom packaging is eco-friendly because it is fully biodegradable, produced with minimal energy consumption, and made from repurposed agricultural waste, which reduces landfill contributions and aligns with sustainable manufacturing practices.

Biodegradability

Mushroom packaging exhibits complete biodegradability, decomposing naturally within 30 to 90 days in composting conditions. Unlike synthetic materials, it leaves no toxic residues, instead enriching the soil with organic nutrients. This property makes it particularly advantageous in industries seeking to minimize landfill contributions.

Energy Efficiency

The production of mushroom packaging requires significantly less energy compared to traditional materials like polystyrene. The mycelium growth process relies on ambient conditions and does not necessitate high-temperature or high-pressure manufacturing, reducing the overall carbon footprint of the material.

Environmental Impact

By utilizing agricultural waste as a primary input, mushroom packaging repurposes byproducts that would otherwise contribute to waste streams. Its compostable nature further supports circular economy principles, aligning with global efforts to reduce reliance on non-renewable resources.

What are the Characteristics of Mushroom Packaging?

Mushroom packaging showcases several performance characteristics that make it a viable alternative to traditional packaging materials. These attributes include durability, protection capabilities, and lightweight design, which are essential for various industrial applications.

Durability and Protection

Mushroom packaging is designed to provide reliable protection for fragile items during transportation. Its natural shock-absorbing properties enable it to withstand impacts, making it an excellent choice for industries such as electronics and consumer goods.

Lightweight Design

The lightweight nature of mushroom packaging contributes to reduced shipping costs and improved handling efficiency. This characteristic is particularly advantageous in logistics and e-commerce, where weight impacts operational performance and cost-effectiveness.

What are the Uses of Mushroom Packaging?

Mushroom packaging is utilized across multiple industries, including electronics for protecting sensitive devices, consumer goods for eco-friendly product presentation, and the food and beverage sector for sustainable packaging tailored to single-use applications.

Electronics Packaging

Mushroom packaging is increasingly used to encase electronic devices, offering both protection and sustainability. Its ability to cushion sensitive components without generating static electricity makes it a preferred choice for manufacturers aiming to reduce environmental impact.

Consumer Goods

In the consumer goods sector, mushroom packaging is employed for items such as cosmetics, small appliances, and specialty products. Its customizable molding capabilities allow for tailored designs that enhance product presentation while maintaining eco-friendliness.

Food and Beverage Industry

Although still in early development stages, mushroom packaging shows potential for use in food and beverage applications. Its compostable nature aligns with the industry’s push toward sustainable packaging solutions, particularly for single-use items.

What are the Advantages of Mushroom Packaging Over Traditional Materials?

Mushroom packaging offers several distinct advantages over conventional materials like polystyrene and plastics. These benefits include environmental sustainability, reduced energy consumption during production, and compatibility with circular economy principles.

Sustainability and Biodegradability

Unlike polystyrene, which can persist in landfills for centuries, mushroom packaging decomposes completely within 30 to 90 days under composting conditions. This biodegradability ensures it leaves no toxic residues, instead enriching soil with nutrients.

Energy Efficiency

The production process of mushroom packaging consumes significantly less energy compared to traditional materials. The low-energy requirements of mycelium cultivation eliminate the need for high-temperature or high-pressure manufacturing, reducing the material’s carbon footprint.

Resource Utilization

By repurposing agricultural waste such as corn husks and hemp stalks, mushroom packaging minimizes reliance on virgin resources. This approach aligns with sustainable manufacturing practices and reduces landfill contributions.

What are the Current Limitations of Mushroom Packaging?

Mushroom packaging, while innovative and eco-friendly, faces several limitations that hinder its widespread adoption. These challenges include scalability, production speed, and cost competitiveness with traditional materials like plastic. The current manufacturing process, which relies on natural mycelium growth, is slower compared to the automated production of synthetic alternatives. The cost of producing mushroom packaging remains higher, particularly when economies of scale have not yet been achieved.

Another limitation is its performance under certain conditions. For example, mushroom packaging has limited moisture resistance, which restricts its use in environments prone to high humidity or direct exposure to liquids. Similarly, its thermal insulation properties require further refinement to meet the demands of industries such as food and beverage, where temperature control is critical.

Despite these challenges, ongoing research and development aim to address these issues. Innovations in material science and mycelium cultivation techniques are expected to improve production efficiency, enhance material properties, and lower costs, paving the way for broader adoption of mushroom packaging in the future.

What is the Future Potential of Mushroom Packaging?

The future potential of mushroom packaging lies in its ability to address current limitations and expand its applications across various industries. As research progresses, advancements in material science aim to improve the scalability, production speed, and cost-effectiveness of mushroom packaging, making it a competitive alternative to traditional materials.

Ongoing innovations focus on enhancing performance characteristics such as moisture resistance and thermal insulation, which are critical for broader adoption in sectors like food and beverage. Additionally, the development of automated production techniques could accelerate manufacturing processes, reducing costs and increasing accessibility for mass-market use.

With its environmentally sustainable attributes and alignment with circular economy principles, mushroom packaging is well-positioned to meet growing consumer and industry demands for eco-friendly solutions. These advancements could pave the way for mushroom packaging to become a mainstream choice for sustainable packaging, contributing significantly to global efforts in reducing environmental impact.