Mylar bags come in various sizes defined by their length, width, and height, which are essential for determining their suitability for different packaging needs. These dimensions affect storage capacity, sealing efficiency, and compatibility with specific products. Understanding these measurements helps manufacturers select the right size for their application, considering factors like barrier properties and intended use.

Standard Mylar bag dimensions include length (longer side), width (shorter side), and height (gusset, for expandable depth). Common sizes range from small 4″ x 6″ pouches to large 20″ x 30″ storage bags, accommodating everything from spices to bulkier items like grains or industrial materials. Selecting the appropriate size ensures optimal use of space, product protection, and ease of storage or transportation. Customization allows manufacturers to tailor Mylar bags for specific product dimensions, storage conditions, and branding requirements. Dimensional tolerances and manufacturing constraints are considered to ensure consistency and functionality. Properly chosen Mylar bag sizes improve storage efficiency, reduce waste, and support product presentation in retail and industrial settings.

- What Are the Standard Dimensions of Mylar Bags?

- How Are Mylar Bag Sizes Determined for Specific Applications?

- What Factors Influence the Customization of Mylar Bag Sizes?

- 1. Dimensional Tolerances and Manufacturing Constraints

- 2. Product-Specific Considerations

- 3. Branding and Labeling Requirements

- 4. Storage and Transportation Efficiency

- 5. Cost Implications of Customization

- How Do Mylar Bag Sizes Affect Storage and Transportation?

What Are the Standard Dimensions of Mylar Bags?

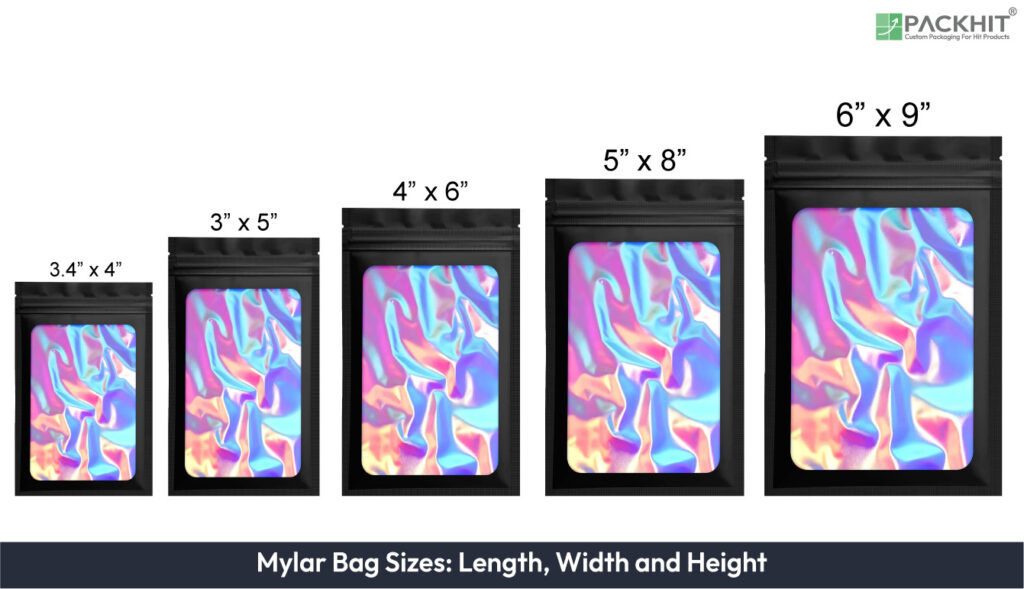

Mylar bags are typically measured in three dimensions: length, width, and height. These measurements are expressed in inches or millimeters, depending on regional standards. The length refers to the longer side of the bag, the width to the shorter side, and the height (or gusset) to the depth created when the bag is expanded. Standard sizes range from small pouches, such as 4″ x 6″, to larger storage bags, such as 20″ x 30″. Variations in these dimensions allow manufacturers to accommodate a wide range of product types, from small, lightweight items to bulkier goods requiring greater storage volume.

Length and Width: Flat Dimensions

The length and width of a Mylar bag are measured when the bag is laid flat. These dimensions determine the bag’s surface area and are critical for products that require a snug fit to minimize excess air or movement. For example, a 10″ x 14″ bag is suitable for medium-sized items such as dried fruits or grains, while smaller dimensions like 6″ x 9″ are ideal for compact items such as spices or seeds. The flat dimensions also influence the sealing process, as larger bags may require specialized sealing equipment to ensure airtight closures.

Height (Gusset): Depth and Expandability

The height, often referred to as the gusset, is a key dimension for stand-up pouches or bags designed to hold bulkier items. This measurement represents the depth of the bag when fully expanded and is particularly important for products requiring vertical storage or display. For instance, a 12″ x 16″ x 4″ bag includes a 4-inch gusset, providing additional volume for items such as coffee beans or pet food. Gusseted bags are commonly used in retail settings where shelf presence and ease of access are priorities.

How Are Mylar Bag Sizes Determined for Specific Applications?

The selection of Mylar bag sizes is influenced by the type of product being packaged, the required storage conditions, and the intended use case. For food products, dimensions must account for both the volume of the contents and the need for an airtight seal to preserve freshness. In industrial applications, larger bags with reinforced gussets may be necessary to accommodate heavy or irregularly shaped items. Additionally, the choice of size must align with the packaging machinery used, as some equipment may have limitations on the maximum or minimum bag dimensions it can handle.

Volume and Capacity Considerations

The internal volume of a Mylar bag, determined by its length, width, and height, dictates its storage capacity. For instance, a 1-gallon Mylar bag typically measures 10″ x 14″, while a 5-gallon bag may measure 18″ x 28″. These capacities are essential for bulk storage applications, such as long-term food preservation or industrial material packaging. Manufacturers often provide size charts correlating dimensions with approximate capacities to assist in selecting the appropriate bag for specific needs.

Product-Specific Requirements

Certain products impose unique dimensional requirements on Mylar bags. For example, pharmaceutical items may require small, precisely sized pouches to ensure accurate dosing and prevent contamination. Conversely, agricultural products like seeds or fertilizers may necessitate larger bags with gussets to accommodate high volumes while maintaining structural integrity. Custom sizing options are often available for specialized applications, allowing manufacturers to tailor the dimensions to their exact specifications.

What Factors Influence the Customization of Mylar Bag Sizes?

Customization of Mylar bag sizes is influenced by dimensional tolerance, specific product requirements, storage conditions, and branding objectives. The factors that influence the customisations of mylar bag sizes are given below:

1. Dimensional Tolerances and Manufacturing Constraints

The production of customized Mylar bags must account for dimensional tolerances, typically within a range of ±1-2 mm. These tolerances ensure batch consistency while accommodating minor material or process variations. Larger bags often require reinforced seams or additional gussets to maintain durability and structural integrity, especially in applications involving heavy or bulky contents. Manufacturing constraints, such as the maximum width of Mylar film rolls or machinery capabilities, also influence the feasible range of dimensions.

2. Product-Specific Considerations

Different products impose distinct dimensional requirements. For instance, pharmaceutical items may demand small, precisely sized pouches to maintain dosage accuracy and prevent contamination. Conversely, agricultural products, such as seeds or fertilizers, often require larger bags with gussets to accommodate high volumes while ensuring durability. Custom sizing ensures that the packaging aligns with the functional and regulatory needs of the product.

3. Branding and Labeling Requirements

The surface area of a Mylar bag directly affects its branding potential. Larger bags provide ample space for printed designs, product details, and logos, enhancing visibility in retail environments. Smaller bags, while more compact, prioritize efficient storage and functionality. Custom dimensions can be strategically chosen to balance aesthetic appeal with practicality, ensuring that the packaging supports the product’s market positioning and consumer engagement.

4. Storage and Transportation Efficiency

Customized dimensions also address logistical considerations, such as storage optimization and transportation. Bags designed to fit specific shelving systems or pallet configurations can improve warehouse efficiency and reduce handling costs. For example, precise sizing minimizes wasted space during stacking or shipping, ensuring that the packaging contributes to cost-effective logistics without compromising product protection.

5. Cost Implications of Customization

While customized Mylar bags offer tailored solutions, they may involve additional costs due to specialized production processes or unique material requirements. Manufacturers must weigh these costs against the functional and branding benefits, ensuring that the investment aligns with overall operational goals. Bulk orders or standardized custom sizes can help mitigate expenses while still meeting specific needs.

How Do Mylar Bag Sizes Affect Storage and Transportation?

The dimensions of Mylar bags significantly impact storage efficiency and transportation logistics. Smaller bags are easier to stack and store, making them ideal for compact storage spaces or retail displays. Larger bags, while offering greater capacity, may require additional considerations for stacking stability and palletization. The choice of size must balance the need for efficient storage with the practicalities of handling and transportation.

Stacking and Palletization

Proper stacking and palletization depend on the uniformity and stability of Mylar bag dimensions. Bags with consistent length, width, and height are easier to arrange in stacks, reducing the risk of shifting during transit. For bulk storage, larger bags may be palletized using specialized equipment to ensure even weight distribution and prevent damage to the contents.

Space Optimization in Warehousing

In warehousing environments, the dimensions of Mylar bags influence space utilization and inventory management. Smaller bags can be stored in bins or on shelves, while larger bags may require dedicated storage areas or racks. Optimizing bag sizes for specific storage conditions can improve operational efficiency and reduce costs associated with wasted space or overstocking.