Products

Explore Eco-Friendly Custom Box Materials To Store and Ship Your Products

Discover a wide range of eco-friendly and sturdy custom box materials for storing, packaging and shipping your products. You can explore our customizable options to find the ideal packaging solution for your product and brand needs.

Metalized Boxes

Order custom printed metalized boxes for safely storing, organizing, holding, and shipping your products. Choose from a wide range of designs, styles

Rigid Boxes

Get custom printed rigid boxes for safely storing, organizing, presenting, and shipping your products. Choose from a wide range of designs and styles

Kraft Boxes

Buy custom kraft boxes for safely storing, organizing, presenting, and shipping your products. Choose from a wide range of designs and styles for dura

Kraft Cigarette Boxes

Order custom kraft cigarette boxes for safely storing, organizing, shipping and displaying your cigarettes. Choose from a wide range of designs, shape

Magnetic Closure Rigid Boxes

Get custom printed magnetic closure rigid boxes for safely storing, organizing, presenting and shipping your products. Choose from a wide range of des

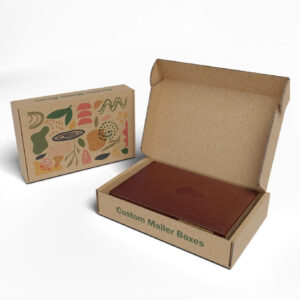

Corrugated Boxes

Get custom printed corrugated boxes for safely storing, organizing, presenting, and shipping your products. Choose from a wide range of designs and st

Cardboard Boxes

Get custom printed cardboard boxes for safely storing, organizing, presenting, and shipping your products. Choose from a wide range of designs and sty

Cardboard Cigarette Boxes

Get custom cardboard cigarette boxes for safely storing, organizing, shipping and displaying your cigarettes. Choose from a wide range of designs, sha

Bux Board Boxes

Order custom bux board boxes for safely storing, presenting, and shipping your products. Choose from a wide range of designs and styles for durable, e

Cardboard Ammo Boxes

Get custom-printed cardboard ammo boxes for safely storing, organizing, presenting, and shipping ammunition products. Choose from a wide range of desi

Need More Options for Custom Boxes and Packaging?

Connect in real-time with our packaging specialists for free consultation and instant quote.

Strong and Durable Custom Box Materials To Protect Your Products

Custom box materials are strong and durable in nature to protect your products from external damage. The materials and cover materials for custom boxes come with customization options to fit the product needs. The durable, lightweight and portable properties of custom box materials ensure the efficient storage and secure shipping of packaging products.

The custom box materials are responsible for printability, logos, and branding by enhancing the visual appearance of products packaging. The biodegradable custom box materials are eco-friendly, recyclable, and cost-effective by assuring smooth and safe shipping.

Custom box materials include following features:

- Customizable to fit product dimensions

- Durable and sturdy

- Lightweight and portable

- Printable logos and branding

- Easy to stack for efficient storage

- Eco-friendly and recyclable

- Cost-effective and smooth shipping

Custom Design, Style, and Material

Inside and Outside Printing Options

Cost-saving with Bulk Orders

Unlimited Order Quantity

Doorstep Delivery in 15 to 18 Business Days

What Materials Are Custom Boxes Made Of?

Custom boxes are made from a variety of materials comprising specific features such as durability, sustainability, and cost-effectiveness. The materials used to manufacture custom boxes are listed below:

- Cardboard

- Paperboard

- Kraft Paper

- Card Stock

- Corrugated Fiberboard

- Rigid

Custom boxes are made up of different materials based on the product type such as cardboard, paperboard, kraft paper, card stock, corrugated fiberboard, and rigid. You can customize custom box packaging from above-mentioned materials that suits your product or brand preferences.

Cardboard

Cardboard is a material made from paper pulp layers that are processed to create a strong and durable material for different packaging needs. Cardboard is a generic term used for heavy-duty paper-based products such as corrugated fiberboard, paperboard, carton board, and folding carton.

Cardboard material is used in the packaging industry due to its strength, versatility, and cost-effectiveness. The common types of paper-based products include corrugated cardboard, paperboard, and rigid cardboard.

Cardboard material is mainly used for its stackable storage, protective packaging, lightweight nature, cost-effectiveness, recyclability and smooth shipping of products for retail and other packaging industries.

Paperboard

Paperboard is a thick paper-based material made from cellulose fibers of wood or recycled paper and characterized by its foldability and rigidity.

Paperboard material is used in the packaging industry due to its lightweight yet sturdy nature, folding capacity, and a preferred choice for printing, lamination and coatings. The classification of paperboard material includes folding boxboard, chipboard, kraft board, laminated board, solid bleached board, solid unbleached board, containerboard, linerboard, and binerboard.

Paperboard material is used for branding, high quality printing, fine finishing, precise packaging of products, enhancing functionality and aesthetic appeal, and protecting products during shipping.

Card Stock

Card stock, also known as cover stock and pasteboard, is a thick paper and more durable than regular paper but thinner than other forms of paperboard. Card stock material has a smooth yet textured, metallic, and glossy surface.

Card stock material in the packaging industry is used for business cards, postcards, and playing cards, etc., due to its sturdier and durable features. Card stock is valued for its durability and flexibility, solid and pliable surface for printing and finishing, foldability and molding capacity, and lightweight packaging solution for products.

Card stock is commonly used for product packaging, protecting goods, smooth shipping and delivering different retail and other industries products.

Corrugated Fiberboard

Corrugated fiberboard, commonly known as corrugated cardboard or corrugated, is a type of packaging material consisting of a fluted corrugated sheet and two flat linerboards. The inner fluted layer is known as corrugation that provides strength and rigidity, whereas linerboards offer a smooth surface for printing.

Corrugated fiberboard in the packaging industry is used due to its strength, lightweight nature, customizable options, cost-effectiveness, sustainable properties and rough handling of products during shipping.

Corrugated fiberboard is used for shipping boxes by protecting goods of retail and other packaging industries. The characteristics of corrugated material include the printability for branding and product information, the stackability to store and organize products, custom inserts and dividers to add cushion effect in order to prevent damage during shipping.

Kraft Paper

Kraft paper is a type of paper or paperboard (cardboard) produced from chemical pulp in the kraft process. Kraft paper material has high tensile strength and durability that makes it a good fit for product packaging.

Kraft paper in the packaging industry is valued for its versatile nature and eco-friendly properties. Kraft material is used due to its ability to withstand rough handling by providing strong protection to packaging products.

Kraft paper is commonly used to make bags, wrapping papers, padded mailers, eco-friendly boxes, shipping and mailing products, and other types of packaging boxes. The specific attributes of kraft paper material include the strong barrier nature against damage, the ability to protect items from scratches and dust, the printability for branding, and recyclable packaging solution for different packaging industries products.

Rigid

Rigid material is a type of packaging material known for its stiffness, strength, and structural integrity to products. Rigid material provides robust support by maintaining the shape and protecting the products from damage.

Rigid material in the packaging industry is used to store, organize, and keep safe the products from rough handling during transit. Rigid materials are used when products are fragile and require additional support to prevent damage and provide premium packaging to high-end products.

Rigid material provides rigidity and resistance to shield delicate products, reflects luxury packaging, ensures safety from external factors by maintaining presentation of packaging products.

What Are the Cover Materials for Custom Boxes?

The cover paper materials for custom boxes are used due to printability in order to enhance functionality and aesthetic quality of products. The cover paper materials include:

- Solid color paper

- Custom printed paper

- Foil paper

- Laminated paper

- Embossed paper

- Matte paper

- Gloss paper

The most commonly used cover paper materials are solid color paper, custom printed paper, laminated, matte and gloss papers. You can customize custom box packaging from aforementioned cover materials that meet your products packaging demands.

Solid Color Paper

Solid color paper is a colored paper available in different shades and provides a consistent color throughout the paper.

Solid color paper material is used for branding purposes when products require solid and vibrant color covering. This cover material enhances brand recognition with consistent colors by offering a clear appearance of product packaging.

Custom Printed Paper

Custom printed paper is a type of cover material that is used for specific designs, patterns, or logos to be printed on the surface.

Custom printed paper material is mainly used for personalized packaging to promote branding. This cover material provides flexibility in designing and customization, incorporates graphics, logos, and text, and enhances brand recognition.

Foil Paper

Foil paper is a type of cover material that has a metallic foil layer applied to its surface. The metallic foil layer is available in gold, silver and many other metallic colors to give an aesthetic appearance to product packaging.

Foil paper material is used for luxury packaging of high-end products to provide a premium look.

Laminated Paper

Laminated paper is a type of cover material that has a thin plastic film applied to its surface which can be glossy, matte, or satin.

The laminated paper material is used due to its durable strength for packaging products of retail and other industries. This cover material is used to enhance strength, water resistance, smooth finishing and to protect against scratches, scuffs, and moisture.

Embossed Paper

Embossed paper is a type of cover material that has raised texture created by pressing the paper with a patterned die.

The embossed paper material is used for luxury packaging of products to give a premium look. This cover material is used to enhance the quality of packaging by providing a visually appealing texture to products packaging.

Matte Paper

Matte paper is a type of material that has non-glossy flat finishing which reduces the glare and reflections.

Matte paper material is used to provide a high-quality finish, to enhance the color accuracy without glare, and is less prone to show smudges on box packaging.

Gloss Paper

Gloss paper is a type of material that has a shiny and reflective coating which enhances the vibrancy of printed colors and images on packaging boxes.

The gloss paper material is used to give a high visual impact to products packaging by providing a shiny and glossy look. This cover material offers a smooth and shiny surface to enhance print quality and to protect the packaging products from moisture and dirt.

What Is the Importance of Paper-Based Packaging Materials?

The importance of paper-based packaging materials such as cardboard, card stock, paperboard, corrugated fiberboard, kraft paper and rigid covers the key elements and their usage in the packaging industry. These packaging materials are used due to their versatility, strength, lightweightness, stackable storage, protective packaging, environmentally-friendly nature, and cost-saving shipping and transportation of packaging products.

The selection of right material for product packaging is significant because the paper packaging materials are responsible for branding that enhances the functionality and aesthetic appeal of products.

What Makes Custom Box Materials Durable and Sturdy?

Paper-based packaging materials are durable and sturdy because of high-quality fibers which give flexibility and tensile strength to increase the durability. The density and thickness of paper material also provides the sturdiness and rigidity while remaining lightweight.

The design of packaging itself also contributes to the durability and sturdiness because features like flap, folds, and creases help to distribute weight and force evenly, enhancing the integrity of products packaging.

How Do Custom Box Materials Ensure Safe Shipping of Products?

Custom box materials ensure safe and secure shipping of products because of their durable, sturdy, cost-effective, eco-friendly and lightweight properties. The high folding strength of custom box materials protect the products from rough handling and external damage during shipping and transport.

The fluted layer in custom boxes protects the products from external shocks and bumps during transport. Furthermore, the custom inserts and other protective materials secure the products from distortion, deterioration and damage.

What Are the Benefits of Using High-Quality Custom Packaging Materials?

The benefits of using high-quality custom packaging materials are listed below:

- Provide enhanced protection for products during shipping by minimizing the risk of damage from shock bumps, drops, and crushing.

- Strengthen brand recognition with good printing quality by incorporating brand logos, colors and text on custom boxes.

- Elevate the perceived value of the product packaging box and contribute to customer satisfaction.

- Reduce the shipping cost with right packaging materials and bulk orders for your products packaging.

- Minimize waste and pollution by choosing biodegradable or recyclable materials and attracting eco-conscious customers.

The above-mentioned benefits and features of paper-based materials ensure the durability, versatility, sustainability and affordability of custom box packaging.

What Factors Need To Be Considered When Choosing Custom Box Material?

Choosing the right material for custom boxes involves considering some factors to ensure the boxes meet the expected requirements, usage, cost-effectiveness, and provide adequate protection. The key factors are listed below:

Purpose and Functionality: The right material is responsible for providing protection to product needs in order to avoid breakage and damage during transit.

Material Types: The material types such as cardboard, paperboard, corrugated etc., are considerable for custom box packaging due to their durable, resistant, strong and lightweight nature.

Customization Options: The selection of box material that fit the product needs can be customized with custom inserts, compartments, dividers, and windows.

Cost-effectiveness: The purchasing of appropriate materials in bulk for product packaging can reduce cost and overall budget.

Branding: The suitable materials and cover materials are responsible for enhancing brand perception and aesthetic appearance of product packaging.

Environmental Impact: The choice of recyclable and biodegradable materials support the sustainable and eco-friendly product packaging.

Storage and Organization: The box materials are considerable for storing and organizing products by protecting from dust, moisture and temperature fluctuations.

Shipping and Transportation: The sturdy and durable materials are reliable because they can withstand rough handling by providing protection during shipping and transportation.

The aforementioned factors should be considered while choosing the suitable material for custom boxes ensuring the functionality, cost-effectiveness, brand recognition and customer expectations.

Are Custom Packaging Box Materials Eco-Friendly and Recyclable?

Yes, custom packaging box materials are designed to be eco-friendly and recyclable, because the materials are biodegradable that help in reducing environmental impact and attract eco-conscious customers.

Are Custom Box Materials Durable?

Yes, custom box materials are durable in nature that can withstand rough handling, shipping, and external pressure by storing and protecting products from damage.

Are Paper-Based Custom Boxes Better Than Other Materials?

Yes, paper-based custom boxes are preferred over other materials due to its durable, sturdy, lightweight, moisture-resistant, and eco-friendly nature. Paper-based materials are easily decomposed than other packaging materials and can be reused multiple times.

Can Custom Box Materials Be Tailored to Specific Industry Needs?

Yes, custom box materials can be tailored to meet specific needs of different industries such as retail, e-commerce, food, electronics, pharmaceuticals, apparel and fashion, cosmetics, stationary, and toys etc.

How Does the Choice of Box Material Affect the Overall Cost of Packaging?

The choice of box material affects the overall cost of packaging due to durability and quality of material, using custom options of choosing material, eco-friendly nature, and bulk orders of custom boxes.

Can Custom Box Materials Be Printed With Branding and Logos?

Yes, custom box materials can be easily printed with logos and branding for an effective product packaging in order to enhance your brand recognition.