Material thickness in rigid packaging refers to the distance between the outer surfaces of a material, influencing its durability, load-bearing capacity, and structural support. It is measured using calipers or advanced methods like laser-based gauges. Thicker materials offer better resistance to mechanical stress, while thinner ones are cost-efficient but less durable. The load-bearing capacity improves with thickness, as thicker materials distribute weight more evenly. Thickness selection depends on product characteristics, transportation conditions, environmental exposure, cost, sustainability, and branding needs. Material composition also affects thickness requirements, with high-density materials providing strength at lower thicknesses.

What is Material Thickness in Rigid Packaging?

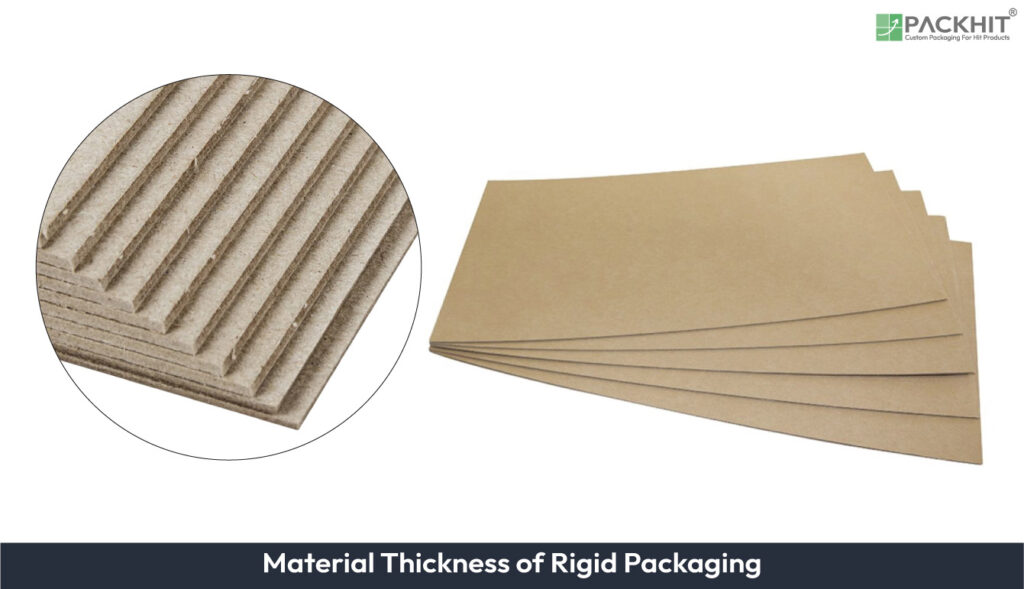

Material thickness refers to the measurable distance between the two outer surfaces of a packaging material, typically expressed in millimeters (mm) or micrometers (µm). In rigid packaging, this attribute directly correlates with the material’s ability to withstand mechanical stress, provide structural support, and maintain dimensional stability. Common materials used in rigid packaging include paperboard, corrugated fiberboard, and molded pulp, each offering distinct thickness ranges suited to specific applications.

For paper-based rigid packaging, thickness is often categorized into lightweight (below 1 mm), medium-weight (1–3 mm), and heavyweight (above 3 mm) grades. These classifications enable manufacturers to align packaging specifications with product requirements, including fragility, weight, and storage conditions.

How is Thickness Measured in Rigid Packaging?

Thickness measurement in rigid packaging materials is typically conducted using calipers or micrometers, ensuring precision and consistency. Advanced methods, such as laser-based thickness gauges, are utilized in high-volume production lines to enable real-time monitoring and quality control. The measurement process accounts for variations caused by material density, surface texture, and manufacturing processes, ensuring that the final product meets specified tolerances.

How Does Material Thickness Impact the Durability of Rigid Packaging?

The durability of rigid packaging is fundamentally influenced by its material thickness. Thicker materials exhibit superior resistance to mechanical stress, such as punctures, compression, and tears, making them ideal for heavier or fragile items. On the other hand, thinner materials may reduce durability but offer cost efficiency and lower environmental impact. For example, corrugated fiberboard with a thickness of 4 mm can withstand weights up to 30 kg, whereas a thinner 2 mm variant is limited to supporting approximately 15 kg. Selecting the right thickness is crucial for ensuring the longevity and protective capabilities of packaging under specific conditions.

How Are Transportation and Sustainability Compromised in Rigid Packaging?

Transportation and sustainability considerations are closely tied to material thickness. Thicker packaging materials can increase the overall weight of shipments, leading to higher transportation costs and greater fuel consumption, which negatively impacts carbon footprints. Conversely, thinner materials may compromise structural integrity, increasing the risk of damage during transit, such as crushing or deformation under heavy stacking. Sustainable strategies, such as using reinforced lightweight materials or optimizing thickness based on product fragility and weight, can help mitigate these trade-offs, ensuring both economic efficiency and environmental responsibility.

How Does Thickness Affect Load-Bearing Capacity of Rigid Packaging?

Load-bearing capacity is a critical performance metric for rigid packaging, directly influenced by material thickness. Thicker materials distribute weight more evenly across the packaging structure, reducing the risk of deformation or collapse under heavy loads. This is particularly important for products requiring vertical stacking during storage or transit.

For instance, a rigid box with a thickness of 3 mm can safely stack up to 10 units of a 5 kg product, whereas a thinner 1.5 mm box may only support half the stacking height. Such considerations are vital for industries like food and beverage, electronics, and consumer goods, where packaging must endure logistical challenges.

What Factors Determine the Optimal Thickness Selection in Rigid Packaging?

The selection of material thickness for rigid packaging is influenced by multiple factors that ensure durability, functionality, and cost-effectiveness. These factors can be categorized into the following:

1. Product Characteristics

The weight, size, and fragility of the product are primary considerations. Heavier products require thicker materials to provide adequate support and prevent deformation, while fragile items may need additional thickness to safeguard against impact and vibration during transit.

2. Transportation Conditions

Packaging thickness must account for the rigors of transportation, including stacking, compression forces, and exposure to varying temperatures or humidity levels. Ensuring adequate thickness helps protect products from damage during storage and shipping.

3. Environmental Exposure

External conditions such as moisture, temperature fluctuations, and UV exposure can affect packaging integrity. For paper-based rigid packaging, additional coatings or treatments may be applied to enhance resilience while maintaining optimal thickness.

4. Cost and Sustainability

Balancing material costs with sustainable practices is essential. While thicker materials may offer better durability, they often require more resources, increasing production costs and environmental impact. Manufacturers must weigh these trade-offs to align with budgetary constraints and eco-friendly objectives.

5. Printing and Branding Compatibility

Rigid packaging often serves as a branding tool, requiring surfaces that support high-quality printing. Thicker materials provide a smoother and more stable surface for branding applications, enhancing visual appeal and marketability.

6. Performance Testing

Manufacturers conduct tests such as compression tests, drop tests, and environmental simulations to determine the optimal thickness for specific applications. These evaluations ensure the packaging can withstand real-world conditions, offering both product safety and customer satisfaction.

How Does Material Composition Affect Thickness Requirements in Rigid Packaging?

Material composition plays a pivotal role in determining the required thickness for rigid packaging. High-density materials, such as solid bleached sulfate (SBS) paperboard, can achieve comparable strength at lower thicknesses compared to lower-density alternatives like recycled fiberboard. This allows manufacturers to optimize packaging design for both performance and cost-effectiveness.