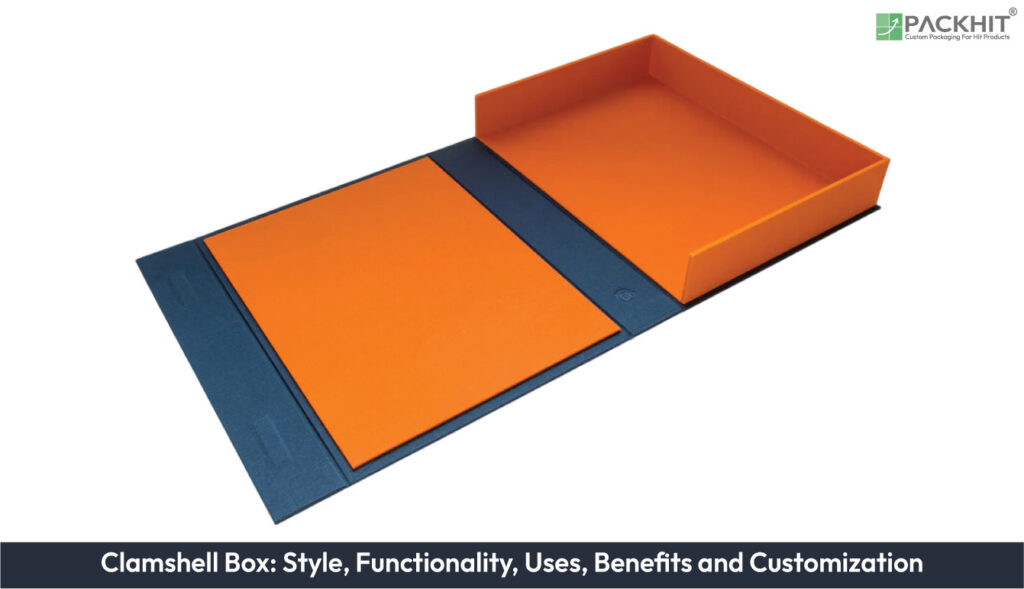

The clamshell rigid box, a subset of rigid packaging solutions, is characterized by its hinged lid design that opens and closes like a clamshell. Clamshell rigid box constructed from durable paperboard materials combines structural integrity with aesthetic versatility, making it a preferred choice for premium product packaging. Clamshell rigid packaging style is widely utilized across industries such as retail, electronics, cosmetics, and luxury goods, where both protection and presentation are paramount. Its customizable features, including size, shape, material finishes, and branding options, allow manufacturers to align packaging with product-specific requirements and market positioning.

- What Defines the Structure of a Clamshell Rigid Box?

- How Does the Clamshell Rigid Box Function in Packaging?

- What are the Common Uses of Clamshell Rigid Boxes?

- What are the Key Benefits of Using Clamshell Rigid Boxes?

- How Can Clamshell Rigid Boxes Be Customized?

- Why are Clamshell Rigid Boxes a Preferred Choice for Manufacturers?

What Defines the Structure of a Clamshell Rigid Box?

The structural design of a clamshell rigid box is defined by its hinged lid, which is integrated into the base, creating a seamless opening and closing mechanism. This design is typically achieved using rigid paperboard, a material known for its high density and durability. The box is constructed in a way that ensures a snug fit between the lid and the base, providing both security and ease of use. The edges are often reinforced to prevent wear and tear, while the interior can be lined with materials such as velvet, foam, or molded inserts to enhance product protection and presentation.

The clamshell design is inherently versatile, accommodating various shapes such as rectangular, square, or even custom geometries. The hinge mechanism can be designed as a full-length spine or a partial hinge, depending on the functional requirements. Additionally, magnetic closures or ribbon ties can be incorporated to enhance the user experience and add a touch of luxury.

How Does the Clamshell Rigid Box Function in Packaging?

The primary function of a clamshell rigid box is to provide a secure and visually appealing packaging solution. Its hinged lid design allows for easy access to the product while maintaining a high level of protection. The rigid paperboard material acts as a barrier against external pressures, moisture, and light, ensuring the product remains intact during storage and transportation.

In addition to protection, the clamshell design enhances the unboxing experience, a critical factor in consumer satisfaction and brand perception. The seamless opening mechanism and the potential for high-quality printing and finishing on the exterior make it an effective tool for storytelling and branding. The interior compartments or inserts can be tailored to hold products securely, preventing movement and potential damage.

What are the Common Uses of Clamshell Rigid Boxes?

Clamshell rigid boxes are employed across a diverse range of industries due to their adaptability and premium appearance. In the retail sector, they are commonly used for packaging high-end electronics such as smartphones, headphones, and wearable devices. The cosmetics industry utilizes these boxes for luxury skincare products, perfumes, and makeup kits, where presentation plays a pivotal role in consumer decision-making.

In the realm of luxury goods, clamshell rigid boxes are often chosen for items like watches, jewelry, and bespoke accessories. Their ability to accommodate custom inserts ensures that delicate items are securely housed. Additionally, these boxes are increasingly used in the food and beverage industry for premium confectionery, wine, and gift hampers, where both protection and aesthetics are critical.

What are the Key Benefits of Using Clamshell Rigid Boxes?

Clamshell rigid boxes offer a comprehensive array of benefits, combining functionality, aesthetic appeal, and environmental considerations. Below is a defined list of their key advantages:

- Durability: These boxes are constructed from high-density rigid paperboard, providing exceptional strength. The material resists crushing and external impacts, ensuring the safety of enclosed products during transportation and storage.

- Customizability: Clamshell rigid boxes can be designed to meet specific requirements for size, shape, and material finishes. Branding elements like logos, color schemes, and high-quality graphic printing can be incorporated seamlessly.

- Enhanced Presentation: The hinged lid design allows for a seamless unboxing experience. With options for premium finishing techniques such as foil stamping, embossing, and UV coating, these boxes elevate the perceived value of the product.

- Product Protection: The snug fit between the lid and base, coupled with the availability of custom inserts like foam or molded compartments, keeps products securely in place and minimizes the risk of damage.

- Eco-Friendliness: Many clamshell rigid boxes are made from recyclable or biodegradable materials. This aligns with the increasing demand for sustainable packaging solutions in various industries.

- Versatility: These boxes accommodate a wide range of products, from luxury goods to electronics, cosmetics, and even premium food items, making them an adaptable packaging solution.

- Premium Closure Options: Features such as magnetic closures, ribbon ties, or snap buttons can be added to enhance both functionality and aesthetic appeal.

How Can Clamshell Rigid Boxes Be Customized?

Customization is a defining feature of clamshell rigid boxes, enabling manufacturers to create packaging that meets specific functional and aesthetic requirements. The customization process typically involves the following elements:

Material Selection

Manufacturers can choose from various grades of rigid paperboard, depending on the desired strength and finish. Options for eco-friendly materials, such as recycled paperboard, are also available.

Exterior Finishes

The exterior of the box can be customized with finishes such as matte or gloss lamination, foil stamping, embossing, or spot UV coating. These finishes not only enhance the visual appeal but also provide additional protection against wear and tear.

Interior Design

The interior can be lined with materials like velvet, satin, or foam to enhance the tactile experience and provide additional protection. Custom inserts can be designed to hold products securely in place.

Branding Elements

Logos, brand colors, and other design elements can be incorporated through high-quality printing techniques. This ensures that the packaging serves as an extension of the brand identity.

Closure Mechanisms

Additional features such as magnetic closures, ribbon ties, or snap buttons can be integrated to enhance functionality and add a premium touch.

Why are Clamshell Rigid Boxes a Preferred Choice for Manufacturers?

Clamshell rigid boxes are favored by manufacturers due to their ability to combine functionality, durability, and aesthetic appeal. Their robust construction ensures product safety, while their customizable features allow for alignment with brand identity and market positioning. The versatility of these boxes makes them suitable for a wide range of products, from luxury goods to consumer electronics, thereby catering to diverse industry needs. Furthermore, their potential for eco-friendly material options addresses the growing consumer demand for sustainable packaging solutions, making them a forward-thinking choice for manufacturers.