IoT packaging integrates Internet of Things (IoT) technology into physical packaging systems, enabling data exchange, connectivity, and enhanced functionality. This revolutionizes packaging by enabling real-time tracking, condition monitoring, and consumer interaction, improving efficiency and customer satisfaction. Manufacturers benefit from enhanced supply chain visibility, reduced waste, and improved product safety. To integrate IoT, businesses must define objectives, select suitable components, collaborate with tech providers, redesign packaging, manage data securely, and run pilot tests. In manufacturing, IoT aids in predictive maintenance, quality control, and inventory management. The IoT-enabled packaging market is rapidly expanding, expected to surpass $7.5 billion, fueled by demand in food, pharma, and electronics. However, challenges include high costs, data security risks, and technical complexity.

- What Is IoT in Packaging?

- How IoT Is Revolutionizing Packaging?

- Why Consider IoT for Packaging?

- Steps for Seamless IoT Integration in Packaging

- 1. Define Objectives and Use Cases

- 2. Select IoT Components

- 3. Collaborate with IoT Technology Providers

- 4. Adapt Packaging Design

- 5. Establish Data Management Protocols

- 6. Pilot Testing and Optimization

- How IoT Helps Manufacturing?

- IoT-Enabled Packaging Market Size and Trends

- Challenges With IoT Systems in Packaging

What Is IoT in Packaging?

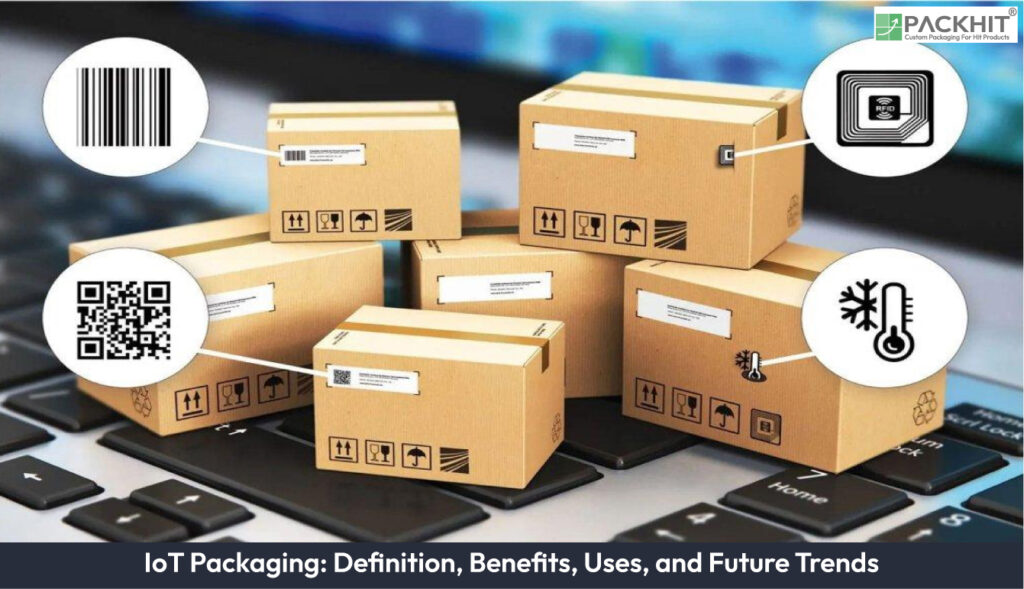

IoT in packaging refers to the integration of Internet of Things technology into packaging systems to enable connectivity and data exchange. IoT, defined as a network of interconnected devices, facilitates communication between packaging and external systems, such as supply chain platforms, consumer devices, and product monitoring systems. This technology transforms packaging from a passive container into an active participant in product lifecycle management.

Core components of IoT packaging include sensors, wireless communication modules, and data processing units. These elements allow packaging to collect, transmit, and analyze data related to product conditions, location, and usage. For example, temperature sensors embedded in food packaging can monitor storage conditions, while RFID tags can track inventory movement across warehouses.

How IoT Is Revolutionizing Packaging?

IoT is revolutionizing packaging by introducing capabilities that were previously unattainable with traditional systems. Key advancements include real-time tracking, condition monitoring, and interactive consumer engagement. IoT-enabled packaging systems can provide manufacturers with detailed insights into product handling, storage conditions, and transportation efficiency, reducing waste and improving supply chain transparency.

For instance, pharmaceutical packaging equipped with IoT sensors can ensure compliance with temperature-sensitive storage requirements, while smart labels on consumer goods can offer personalized product information via mobile apps. These innovations not only enhance operational efficiency but also improve customer satisfaction by delivering tailored experiences and ensuring product integrity.

Why Consider IoT for Packaging?

Manufacturers should consider IoT for packaging due to its measurable benefits across multiple domains. IoT packaging enhances supply chain visibility, reduces operational costs, and improves product safety. By enabling real-time data collection and analysis, IoT systems help identify inefficiencies, prevent spoilage, and optimize logistics.

Additionally, IoT packaging supports sustainability initiatives by enabling better resource management. For example, reusable packaging systems equipped with IoT can track usage cycles and ensure proper maintenance, reducing environmental impact. Furthermore, IoT packaging enhances brand differentiation by offering interactive features that engage consumers and build loyalty.

Steps for Seamless IoT Integration in Packaging

The steps to integrate IoT in packaging are mentioned below:

1. Define Objectives and Use Cases

The first step in integrating IoT into packaging is to identify specific objectives and use cases. Manufacturers must determine whether the primary focus is on tracking, monitoring, consumer engagement, or other functionalities. Clear goals set the foundation for successful implementation.

2. Select IoT Components

Choose appropriate IoT hardware and software components based on the defined objectives. Key elements include sensors, communication modules, and data processing units. For example, temperature sensors can ensure optimal conditions for perishables, while RFID tags facilitate inventory tracking.

3. Collaborate with IoT Technology Providers

Partnerships with IoT technology providers are crucial to ensure compatibility between IoT systems and existing packaging infrastructure. Providers can offer tailored solutions that meet industry-specific requirements while addressing technical challenges such as scalability and integration.

4. Adapt Packaging Design

Packaging design must be optimized to accommodate IoT components without compromising functionality or aesthetics. This includes ensuring sufficient space for embedded devices and maintaining the structural integrity of packaging materials.

5. Establish Data Management Protocols

Develop robust data management protocols to handle the influx of information generated by IoT systems. Secure storage, efficient processing, and real-time analysis are essential to extracting actionable insights while safeguarding sensitive data from potential security breaches.

6. Pilot Testing and Optimization

Conduct pilot tests to validate the functionality and effectiveness of IoT-enabled packaging systems. Use feedback from these trials to optimize hardware and software configurations, ensuring reliability and scalability before full-scale deployment.

How IoT Helps Manufacturing?

IoT packaging significantly benefits manufacturing by streamlining operations and enhancing product quality. Real-time data from IoT-enabled packaging systems allows manufacturers to monitor production processes, identify bottlenecks, and optimize workflows. For example, sensors embedded in packaging can detect anomalies in product handling, enabling immediate corrective actions.

IoT also facilitates predictive maintenance by providing insights into equipment performance and wear. This reduces downtime and extends the lifespan of machinery. Additionally, IoT packaging supports inventory management by tracking product movement and ensuring accurate stock levels, minimizing overproduction and waste.

IoT-Enabled Packaging Market Size and Trends

The IoT-enabled packaging market is experiencing rapid growth, driven by increasing demand for smart solutions across industries. According to industry estimates, the global IoT packaging market is projected to reach $7.56 billion by 2023, with a compound annual growth rate (CAGR) of 5.9%. Key sectors driving this growth include food and beverage, pharmaceuticals, and consumer electronics.

Emerging trends in the market include the adoption of sustainable materials, integration of advanced analytics, and development of reusable packaging systems. Manufacturers are increasingly investing in IoT technologies to enhance product traceability, improve customer engagement, and meet regulatory requirements.

Challenges With IoT Systems in Packaging

Despite its advantages, IoT packaging faces several challenges, including high implementation costs, data security concerns, and technical complexity. The integration of IoT components into packaging systems requires significant investment in hardware, software, and infrastructure, which may deter small-scale manufacturers.

Data security is another critical issue, as IoT systems generate and transmit sensitive information that must be protected from cyber threats. Additionally, the technical complexity of IoT systems can pose challenges in terms of maintenance and scalability. Manufacturers must address these issues to fully realize the potential of IoT packaging.