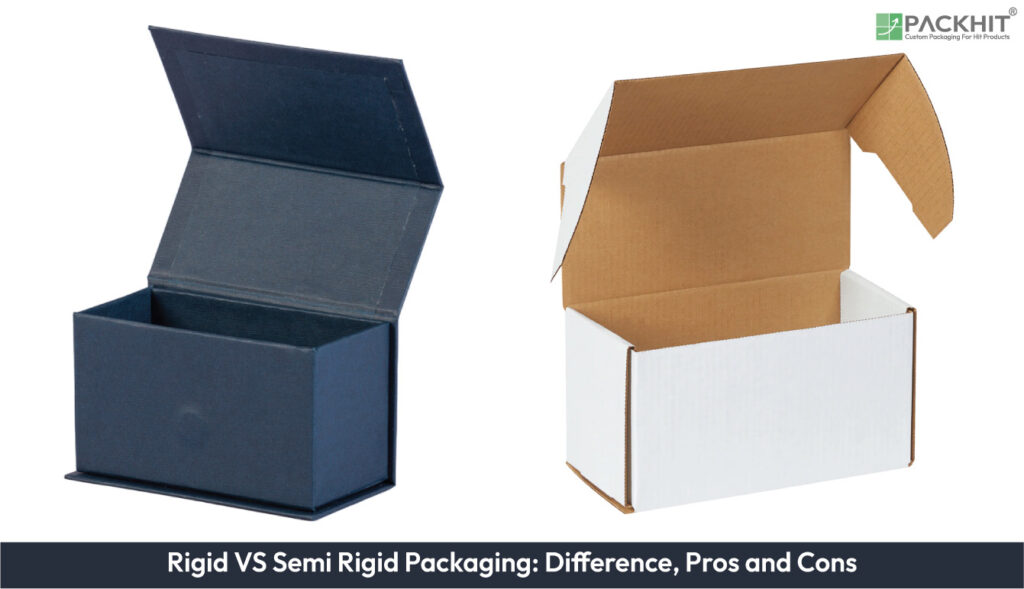

Rigid and semi-rigid packaging represent two distinct categories of packaging solutions, each defined by their structural integrity, material composition, and functional applications. Rigid packaging maintains a fixed shape, offering high structural integrity and durability with materials like glass, metal, and high-density plastics, making it ideal for protecting high-value or fragile products. Its advantages include excellent barrier properties, premium aesthetics, and recyclability, though it comes with drawbacks such as high production costs, weight, and storage inefficiency. Semi-rigid packaging balances structural support and flexibility, using materials like thermoformed plastics and laminated paperboard to provide lightweight, cost-effective, and customizable solutions suitable for food, personal care, and medical applications. While semi-rigid packaging is versatile, its limitations include reduced impact resistance, the need for additional barrier layers, and environmental concerns due to mixed-material compositions. Comparing these two types, rigid packaging excels in protection and presentation for luxury or high-value items, whereas semi-rigid packaging offers adaptability and cost efficiency for lightweight, disposable products, allowing manufacturers to choose based on their product needs, operational priorities, and sustainability goals.

- What is Rigid Packaging?

- What are the Core Properties of Rigid Packaging?

- Applications of Rigid Packaging

- What are the Advantages of Rigid Packaging?

- What are the Limitations of Rigid Packaging?

- What is Semi-Rigid Packaging?

- What are the Core Properties of Semi-Rigid Packaging?

- Applications of Semi-Rigid Packaging

- What are the Advantages of Semi-Rigid Packaging?

- What are the Limitations of Semi-Rigid Packaging?

- What is the Difference Between Rigid and Semi-Rigid Packaging?

- What are the Pros and Cons of Rigid and Semi-Rigid Packaging?

What is Rigid Packaging?

Rigid packaging refers to packaging solutions that maintain a fixed shape and exhibit minimal flexibility under external forces. Common materials used in rigid packaging include glass, metal, and high-density plastics, as well as paperboard in the case of rigid boxes. The defining characteristic of rigid packaging is its structural integrity, which ensures that the packaging does not deform or collapse during handling, storage, or transportation.

What are the Core Properties of Rigid Packaging?

Rigid packaging is defined by its structural integrity, material strength, dimensional stability, and excellent barrier properties, making it ideal for protecting fragile or high-value products during handling, storage, and transportation.

Material Strength: Rigid packaging materials are designed to withstand significant mechanical stress, making them ideal for protecting fragile or high-value products.

Dimensional Stability: The fixed shape of rigid packaging ensures consistent dimensions, which is critical for automated packing lines and shelf presentation.

Barrier Properties: Many rigid packaging materials, such as glass and metal, provide excellent barriers against moisture, oxygen, and light, extending product shelf life.

Applications of Rigid Packaging

Rigid packaging is widely used in industries such as food and beverages, pharmaceuticals, cosmetics, and electronics. For example, glass jars are commonly used for jams and sauces, while rigid plastic containers are preferred for medical devices due to their protective properties.

What are the Advantages of Rigid Packaging?

Rigid packaging offers advantages such as durability for enhanced protection, premium aesthetics for luxury product presentation, and high recyclability with materials like glass and metal, making it a standout choice for products requiring robust and sustainable packaging solutions.

- Durability: Provides superior protection against physical damage.

- Premium Aesthetic: Enhances product presentation, particularly for luxury goods.

- Recyclability: Many rigid materials, such as glass and metal, are highly recyclable.

What are the Limitations of Rigid Packaging?

Rigid packaging limitations include higher costs due to material and production expenses, increased weight leading to elevated transportation costs, and storage inefficiency caused by fixed shapes that occupy more space.

- High Cost: The production and material costs are generally higher compared to flexible alternatives.

- Weight: Rigid packaging tends to be heavier, increasing transportation costs.

- Storage Inefficiency: Fixed shapes can lead to inefficient use of storage space.

What is Semi-Rigid Packaging?

Semi-rigid packaging occupies a middle ground between rigid and flexible packaging, offering partial structural support while retaining some degree of flexibility. Materials commonly used in semi-rigid packaging include thermoformed plastics, laminated paperboard, and aluminum foil composites. This type of packaging is designed to provide a balance between protection, adaptability, and cost-effectiveness.

What are the Core Properties of Semi-Rigid Packaging?

The core properties of semi-rigid packaging include partial structural support offering resilience under pressure, lightweight construction for reduced shipping costs, and customizability through processes like thermoforming to fit specific product shapes and dimensions.

Flexibility: Semi-rigid packaging can deform under moderate pressure but returns to its original shape, providing a degree of resilience.

Lightweight: Compared to rigid packaging, semi-rigid options are lighter, reducing shipping costs.

Customizability: Thermoforming and other processes allow for tailored designs to fit specific product shapes.

Applications of Semi-Rigid Packaging

Semi-rigid packaging is commonly used in food packaging (e.g., yogurt cups, ready-meal trays), personal care products, and certain medical applications. Its ability to combine structural support with lightweight properties makes it ideal for single-use and disposable products.

What are the Advantages of Semi-Rigid Packaging?

Semi-rigid packaging offers a balanced combination of flexibility and support, making it an ideal choice for manufacturers seeking cost-efficient, lightweight, and versatile packaging solutions.

- Cost-Effectiveness: Lower material and production costs compared to rigid packaging.

- Versatility: Suitable for a wide range of products and applications.

- Space Efficiency: Stackable designs optimize storage and transportation.

What are the Limitations of Semi-Rigid Packaging?

Semi-rigid packaging offers less impact resistance than rigid packaging, requires additional barrier layers for optimal protection, and poses environmental challenges due to mixed-material compositions that complicate recycling processes.

- Reduced Protection: Offers less resistance to impact and compression compared to rigid packaging.

- Limited Barrier Properties: May require additional layers or coatings to achieve desired protection levels.

- Environmental Concerns: Often less recyclable than rigid packaging due to mixed-material compositions.

What is the Difference Between Rigid and Semi-Rigid Packaging?

Rigid and semi-rigid packaging differ significantly in terms of material strength, cost, flexibility, and environmental impact. Below is a detailed comparative analysis presented in tabular format, helping manufacturers evaluate the strengths and trade-offs of each packaging type to make informed decisions:

| Feature | Rigid Packaging | Semi-Rigid Packaging |

|---|---|---|

| Material Strength | High durability and resistance to mechanical stress, ideal for fragile or high-value products. | Moderate structural support with resilience under pressure, suitable for lightweight applications. |

| Cost | Higher production and material costs due to premium materials like glass and metal. | Lower costs, leveraging cost-efficient materials such as thermoformed plastics and laminated paperboard. |

| Flexibility | Fixed shape with minimal flexibility, ensuring consistent dimensions and presentation. | Partial flexibility allows adaptability to product shapes while maintaining structural support. |

| Environmental Impact | Highly recyclable with materials like glass and metal, promoting sustainability. | Mixed-material compositions can complicate recycling, posing environmental challenges. |

| Applications | Commonly used in luxury goods, electronics, and pharmaceuticals, requiring robust protection. | Ideal for food packaging, personal care items, and disposable products, emphasizing cost-efficiency. |

By comparing these attributes, manufacturers can identify the packaging type that best aligns with their product requirements, operational priorities, and sustainability goals. For instance, rigid packaging may be preferable for high-value items that demand superior protection and presentation, while semi-rigid packaging offers cost-effective solutions for lightweight, disposable, or adaptable applications.

What are the Pros and Cons of Rigid and Semi-Rigid Packaging?

Rigid packaging excels in durability and premium aesthetics, making it ideal for high-value products that require superior protection and presentation. With materials like glass and metal offering excellent barrier properties, rigid packaging ensures extended product shelf life and maintains its structural integrity under mechanical stress. However, its drawbacks include higher production costs, increased weight that elevates transportation expenses, and storage inefficiency due to its fixed shapes occupying more space.

Semi-rigid packaging, on the other hand, strikes a balance between flexibility and structural support. Its lightweight nature reduces shipping costs, while its adaptability allows customization to fit specific product shapes through processes like thermoforming. Despite its cost-effectiveness and versatility, semi-rigid packaging offers less impact resistance than rigid packaging, may require additional barrier layers for optimal protection, and poses recycling challenges due to mixed-material compositions. These trade-offs highlight the importance of aligning packaging choices with product requirements and operational priorities.