Rigid packaging comprises three primary formats: boxes, tubes, and trays. Boxes (folding cartons, set‑up boxes, die‑cut cartons) give structural protection and high printability. Tubes (paperboard, composite, rigid plastic) secure cylindrical goods and add barrier properties. Trays (molded pulp, thermoformed plastic, paperboard) organize components and absorb shock.

Manufacturers in FMCG, luxury, electronics, and pharmaceuticals use rigid packaging to protect products and present brand information. Examples include Coca‑Cola (printed corrugated cartons for multipacks), Ferrero (molded pulp trays), Gucci and Louis Vuitton (set‑up boxes with branded finishes), Apple and Samsung (die‑cut cartons and anti‑static trays), and Pfizer and Johnson & Johnson (laminated cartons and rigid trays for medical components).

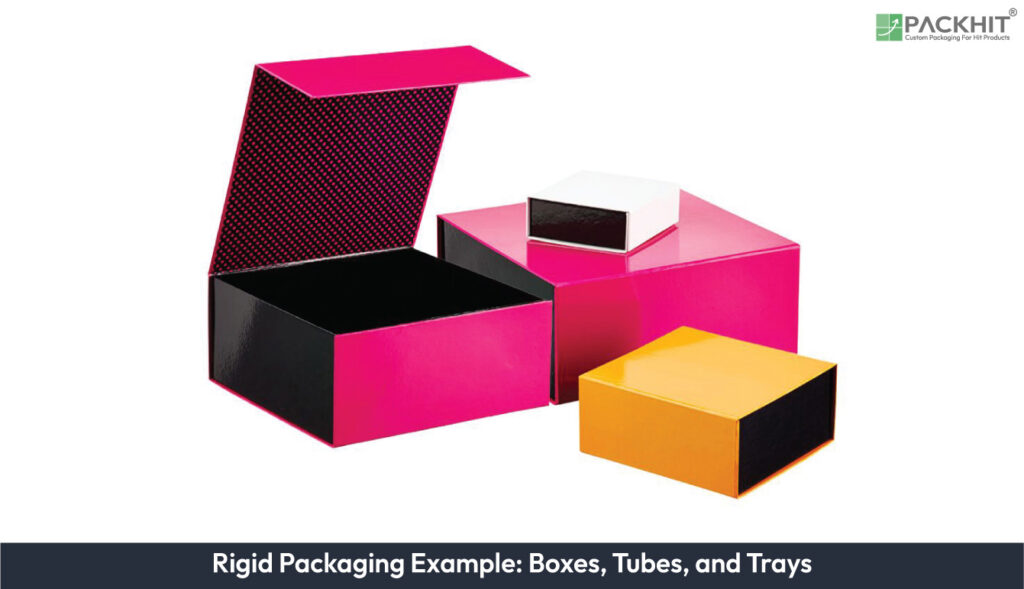

What Are the Examples of Rigid Packaging?

Rigid packaging includes three primary examples: boxes, tubes, and trays. These formats are designed to provide structural integrity and durability, making them ideal for various industries. Boxes offer versatile designs for storage and shipping. Tubes provide precision for cylindrical items, while trays enable efficient organization and protection for a wide range of products.The three key examples of rigid packaging are given below:

1. Rigid Boxes

Rigid boxes are a cornerstone of durable packaging solutions, offering unmatched structural integrity and versatility in design. These boxes are typically made from high-quality materials such as corrugated fiberboard, paperboard, or rigid plastics, which ensure strength and resistance to deformation. Their robust construction makes them ideal for protecting products during transit, storage, and retail display.

Examples of Rigid Boxes

Rigid boxes are distinguished by their structural integrity and versatility, making them a preferred choice across various industries. Below are the primary formats of rigid boxes:

- Folding Cartons

Folding cartons, constructed from paperboard, are lightweight and ideal for retail packaging. These cartons offer excellent printability, enabling manufacturers to include branding elements, product information, and promotional graphics. Widely used in industries such as food, cosmetics, and pharmaceuticals, folding cartons provide an economical yet visually appealing packaging option for lightweight products.

- Rigid Set-Up Boxes

Rigid set-up boxes are known for their premium design and durability. Crafted from sturdy materials like paperboard, these boxes are often used to package luxury goods, electronics, and high-value items. Their rigid construction enhances product protection, while their elegant appearance reinforces brand prestige. Common features include magnetic closures, velvet linings, and premium finishes like foil stamping and embossing.

- Die-Cut Boxes

Die-cut boxes are precision-engineered to fit specific product dimensions, offering customized solutions for industries such as food, consumer electronics, and cosmetics. These boxes are often paired with inserts or foam padding to ensure product stability and protection during transit. Their design flexibility allows manufacturers to create tailored packaging that balances functionality with aesthetic appeal.

2. Rigid Tubes

Rigid tubes are cylindrical packaging solutions designed for strength, precision, and aesthetic appeal. They are commonly constructed from materials such as paperboard, composite materials, and rigid plastics, each selected to meet specific functional and industry requirements. These tubes provide a robust and durable structure, ensuring the safe containment of products during storage, transportation, and display.

Examples of Rigid Tubes

Rigid tubes are versatile cylindrical packaging solutions designed to meet various functional and aesthetic requirements. Below are examples of common types of rigid tubes, each tailored to specific applications:

- Paperboard Tubes

Paperboard tubes, often spiral-wound, are lightweight yet durable solutions. They are ideal for packaging items like posters, cosmetics, and dry foods. Their smooth surfaces allow for vibrant printing, enhancing branding opportunities while maintaining structural integrity during transit and storage.

- Composite Tubes

Composite tubes combine paperboard with layers of metal or plastic, offering enhanced barrier properties such as moisture resistance. These tubes are particularly suited for packaging food products like powdered beverages and pharmaceuticals, where protection against environmental factors is critical.

- Rigid Plastic Tubes

Rigid plastic tubes provide superior strength and clarity, making them ideal for applications that require durability and product visibility. Commonly used for packaging premium cosmetics, such as creams and lipsticks, these tubes align with both functional needs and high-end branding requirements.

3. Rigid Trays

Rigid trays are essential components of durable packaging, offering flat, open designs that prioritize organization, protection, and accessibility. These trays are commonly constructed from materials such as molded pulp, thermoformed plastic, and paperboard, each chosen for its specific functional attributes and industry applications.

Examples of Rigid Trays

Rigid trays are versatile packaging solutions that provide a balance of structural integrity, organization, and accessibility. Below are examples of rigid trays categorized by material type and their respective applications:

- Molded Pulp Trays

Molded pulp trays are made from recycled paper fibers, making them an eco-friendly choice. These trays provide excellent shock-absorbing properties, making them ideal for protective packaging in industries such as food service and electronics. Their sustainable composition aligns with environmentally conscious production practices.

- Thermoformed Plastic Trays

Thermoformed plastic trays are precision-formed to offer clarity, rigidity, and durability. They are widely used in retail displays and medical device packaging, where visibility and structural integrity are essential. These trays are particularly valued for their custom fit and ability to protect fragile items.

- Paperboard Trays

Paperboard trays, often laminated for added durability, offer a balance of lightweight construction and structural strength. These trays are versatile and used in various applications, such as food packaging and product organization. Laminations can improve moisture resistance and enhance the tray’s overall functionality.

Which Brands Use Rigid Packaging?

Multiple global brands use rigid packaging to protect products and present brand information during storage, transport, and retail display.

Coca-Cola

Uses printed corrugated and laminated paperboard cartons for multipacks and seasonal promotional packs to protect bottles and support automated pallet handling.

Ferrero

Uses molded pulp trays and rigid boxes to separate confections, reduce movement, and maintain retail presentation for fragile chocolates.

Gucci

Uses set-up rigid boxes with magnetic closures, fabric lining, and foil stamping to protect leather goods and signal product provenance at retail.

Louis Vuitton

Uses rigid boxes and structured cartons with reinforced corners and branded finishes to protect high-value items and support premium shelf display.

Apple

Uses die-cut rigid cartons with custom paperboard or foam inserts that secure devices, limit relative motion, and match automated packing lines.

Samsung

Uses corrugated rigid boxes and anti-static trays for electronics and components to protect during distribution and comply with handling protocols.

Pfizer

Uses rigid trays and laminated cartons for medical devices and blister packs to provide compartmentalization, tamper evidence, and barrier properties.

Johnson & Johnson

Uses paperboard tubes, rigid trays, and laminated cartons for consumer health products and medical supplies to control moisture and organize components.