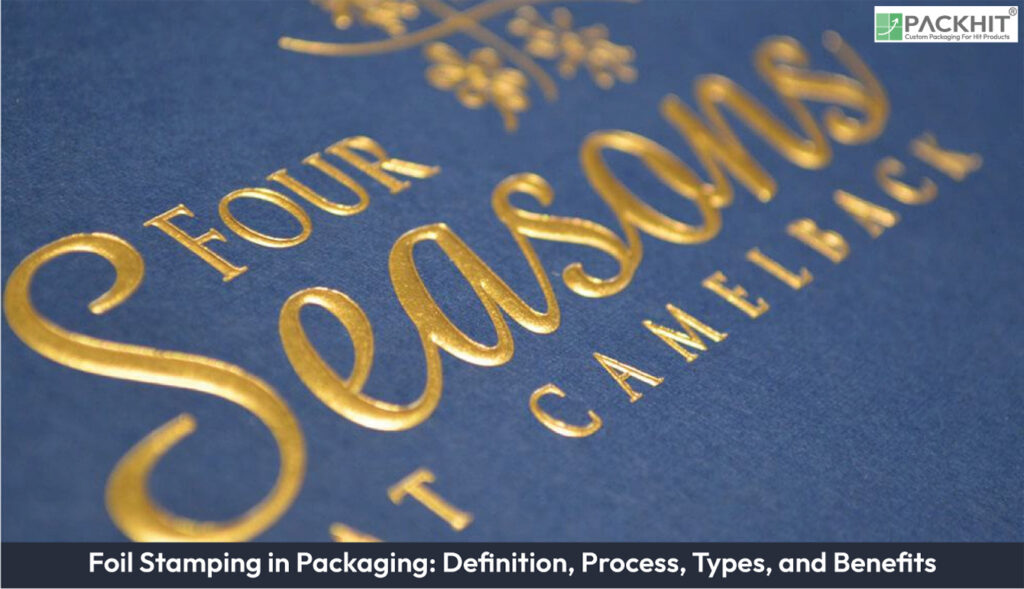

Foil stamping is a specialized printing technique that uses heat, pressure, metal dies, and foil films to create decorative and visually striking designs on packaging materials. This process is widely used in custom packaging to enhance the aesthetic appeal, perceived value, and branding of products. With its ability to produce metallic, glossy, or textured finishes, foil stamping has become a cornerstone in luxury packaging and branding across industries such as cosmetics, electronics, and high-end consumer goods.

- What is Foil Stamping?

- What are the Properties of Foil Stamping?

- What are the Historical Origins and Evolution of Foil Stamping?

- How Does the Foil Stamping Process Work?

- What are the Different Types of Foil Stamping?

- What are the Benefits of Foil Stamping?

- 1. Enhanced Visual Appeal

- 2. Increased Perceived Value

- 3. Versatility in Design

- 4. Anti-Counterfeiting Properties

- 5. Durability

- What are the Applications of Foil Stamping in Packaging?

- What are the Costs and Market Trends of Foil Stamping?

What is Foil Stamping?

Foil stamping is a printing process that involves the application of metallic or pigmented foils onto a surface using heat and pressure. The technique is often employed to create shiny, reflective, or textured designs that elevate the visual appeal of packaging. It is commonly used on materials such as paper, cardstock, leather, and plastic, making it versatile for a wide range of applications.

What are the Properties of Foil Stamping?

Foil stamping is a versatile and dynamic printing technique, distinguished by its unique combination of heat, pressure, and specialized materials. Below are its key features, which make it an essential tool in custom packaging and branding:

- Printing Method: A heat-and-pressure-based technique that transfers metallic or pigmented foils onto a substrate, ensuring a high-quality and durable finish.

- Material Compatibility: Works with a wide range of materials, including paper, cardstock, leather, plastic, and coated surfaces. This adaptability allows its use across various industries.

- Foil Varieties: Employs diverse foil types such as metallic (gold, silver, copper), holographic, pearlescent, and pigmented options to achieve distinctive visual effects.

- Design Features: Produces reflective, matte, glossy, or textured finishes, enhancing the aesthetic value of packaging. It also supports advanced techniques like embossing, debossing, and UV coatings for added depth and complexity.

What are the Historical Origins and Evolution of Foil Stamping?

Foil stamping has a rich history, originating during the Ming Dynasty (1338–1644) as a manual gold-leafing technique. The process evolved significantly during the Industrial Revolution, transitioning to hot stamping presses. Ernst Oeser of Germany patented the first hot-stamping method in 1892, and by the early 1900s, atomized gold on thin polyester films was developed in Europe. The technique gained widespread industrial adoption between the 1950s and 1960s, becoming a staple in luxury packaging.

How Does the Foil Stamping Process Work?

The foil stamping process involves several key steps, each contributing to the creation of a premium and visually appealing design. Below is a detailed breakdown of the process:

1. Design Preparation

The process begins with the creation of a customized metal die that includes the design to be stamped. All parts of the design must be vectorized to ensure proper layout separation and foiling plate creation. The die is then engraved with the desired pattern, which will be transferred onto the packaging material.

2. Material Selection

Foil stamping can be applied to a variety of materials, including paper, cardstock, leather, and plastic. The choice of material depends on the intended application and desired finish. Smooth paper, kraft paper, and coated surfaces are commonly used for packaging.

3. Application of Heat and Pressure

The foil stamping machine uses heat and pressure to bond the metallic or pigmented foil onto the material. A heated metal die presses the foil against the substrate, creating a sharp, detailed imprint. The combination of heat and pressure ensures durability and a high-quality finish.

4. Finishing Touches

Additional enhancements, such as embossing, debossing, or glossy UV coatings, can be integrated with foil stamping to create a more sophisticated and tactile design. These techniques add depth and texture, further elevating the packaging’s appeal.

What are the Different Types of Foil Stamping?

Foil stamping techniques vary based on the method of application and the desired finish. The most common types include:

1. Hot Foil Stamping

Hot foil stamping is the most widely used technique, involving the application of heat and pressure to transfer metallic foil onto a surface. This method is ideal for creating reflective and luxurious finishes, making it a popular choice for high-end packaging.

2. Cold Foil Stamping

Cold foil stamping uses UV light instead of heat to transfer metallic foil. This technique is faster and more cost-effective but offers less durability compared to hot foil stamping. It is often used for applications requiring quick turnaround times.

3. Digital Foil Stamping

Digital foil stamping eliminates the need for metal dies, using digital technology to apply foil directly onto the material. This method is highly versatile and suitable for short-run projects or intricate designs.

What are the Benefits of Foil Stamping?

Foil stamping offers numerous advantages, making it a preferred choice for custom packaging and branding. Key benefits include:

1. Enhanced Visual Appeal

Foil stamping creates a luxurious and eye-catching finish that enhances the aesthetic appeal of packaging. The use of metallic foils, such as gold or silver, adds elegance and sophistication, making products more noticeable on shelves.

2. Increased Perceived Value

The premium look and feel of foil-stamped packaging elevate the perceived value of a product, justifying higher pricing and enhancing brand perception. This is particularly important for luxury goods and high-end consumer products.

3. Versatility in Design

Foil stamping is compatible with a wide range of materials and design elements, including embossing, debossing, and matte or glossy finishes. This versatility allows for creative and diverse packaging designs.

4. Anti-Counterfeiting Properties

Foil stamping enhances the security and authenticity of products by incorporating anti-counterfeiting features. This is especially valuable in industries such as pharmaceuticals and luxury goods.

5. Durability

The heat and pressure used in foil stamping create a durable finish that resists wear and tear, ensuring the design remains intact over time. This makes it ideal for packaging that requires long-lasting visual appeal.

What are the Applications of Foil Stamping in Packaging?

Foil stamping is widely used across various industries to enhance the branding and packaging of products. Common applications include:

- Luxury Packaging: Foil stamping, frequently seen in the packaging of cosmetics, jewelry, and high-end electronics, enhances product presentation by adding metallic or textured finishes that elevate visual appeal and create a sense of luxury.

- Business Cards: Creates premium finishes for professional branding, enhancing tactile and visual appeal to leave a lasting impression.

- Book Covers: Adds decorative and durable designs, making books more visually compelling and resistant to wear.

- Greeting Cards: Provides festive embellishments, such as shiny or holographic elements, for occasions like holidays or celebrations.

- Labels and Stickers: Improves product identification with eye-catching visuals, often integrating anti-counterfeiting features for added security.

What are the Costs and Market Trends of Foil Stamping?

Foil stamping is a premium printing technique that adds 5% to 20% to total packaging costs. The price can increase further for intricate or large foil sections, with full-wrap designs potentially raising costs by $0.50 to $1.50 per unit. Despite these added expenses, its value in luxury and custom packaging makes it a worthwhile investment for manufacturers aiming to enhance product appeal and brand perception.

The global market for hot stamping foil is projected to grow significantly, from USD 1.15 billion in 2023 to an estimated USD 2 billion by the next decade. This growth reflects rising demand for luxury packaging solutions and eco-friendly innovations, driven by the increasing focus on sustainability and premium branding across industries such as cosmetics, electronics, and high-end consumer goods. Manufacturers are continuously exploring advancements in foil materials and techniques to meet evolving market needs while maintaining cost efficiency.

Foil stamping is a versatile and impactful printing technique that enhances the visual appeal, perceived value, and branding of packaging. With its wide range of applications and benefits, it continues to be a preferred choice for manufacturers seeking to create premium and memorable packaging designs. As advancements in technology and sustainability emerge, foil stamping is poised to remain a cornerstone in the packaging industry.