GSM (Grams per Square Meter) and LBS (Pounds per Ream) are two distinct units used to measure the weight and thickness of materials, particularly in the paper and packaging industries. GSM is a metric measurement that quantifies the weight of a single square meter of material, while LBS is an imperial measurement that represents the weight of a ream (500 sheets) of paper based on its basis size. Both units serve as critical benchmarks for determining material quality, durability, and suitability for specific applications. GSM is ideal for industries like printing, packaging, and textiles, as it provides consistent material thickness and durability measurements. LBS, on the other hand, is primarily used in the paper industry, particularly in the U.S, and is tailored to specific paper types and sizes. Conversion between these units helps manufacturers select suitable materials for various applications, from book publishing to packaging design. Emerging trends in both GSM and LBS include the use of digital tools, increased globalization, and a growing focus on sustainability. These trends highlight the evolving nature of material measurement and its role in fostering consistency and eco-friendly practices across industries.

What is GSM (Grams per Square Meter)?

GSM, or grams per square meter, is a globally recognized metric unit that quantifies the weight of material over a defined surface area. It provides a precise understanding of the material’s density, thickness, and weight consistency. For instance, a sheet of paper rated at 120 GSM weighs 120 grams per square meter, regardless of its actual dimensions. This measurement standard eliminates variability caused by size differences and ensures uniformity across material types.

What are the Key Features of GSM?

The key features of GSM are given below:

- Standardized Measurement: GSM is independent of material dimensions, making it a universal metric for comparing materials across industries.

- Density Indicator: Higher GSM values denote denser materials, which often translate to improved durability and quality.

- Versatile Applications: Commonly used in industries such as printing, textiles, and packaging to evaluate material performance and suitability.

- Global Relevance: Adopted internationally, GSM serves as a reliable benchmark for material specifications, facilitating consistency in manufacturing and trade.

- Conversion Potential: Can be converted into imperial units like LBS to accommodate regional standards, especially in North America.

GSM is a fundamental unit in material selection, enabling manufacturers to assess thickness and weight properties with precision. Its simplicity and standardization have made it indispensable in ensuring quality control across diverse applications.

What is LBS?

LBS, or pounds per ream, is an imperial unit that measures the weight of a ream of paper (500 sheets) based on its basis size. Unlike GSM, LBS is dependent on the type and size of the paper being measured. For instance, a 20 lb bond paper and a 50 lb cover paper may have different thicknesses despite having the same weight in pounds.

What are the Core Attributes of LBS?

LBS (Pounds per Ream) is a critical unit of measurement in the paper and packaging industries, particularly in North America. It provides essential insights into the paper’s weight and suitability for various applications. Below are the core attributes of LBS:

- Imperial Standard: LBS is an imperial measurement system widely adopted in the United States and neighboring regions, making it essential for industries focused on local markets.

- Basis Weight: The LBS value depends on the basis size of the paper (e.g., bond, text, or cover), which varies by paper type and usage.

- Application-Specific: Heavily utilized in printing, publishing, and packaging to ensure the material meets specific weight and thickness requirements.

- Material Versatility: Suitable for assessing a wide range of paper types, from lightweight bond paper used in offices to heavier cover paper for packaging and promotional materials.

- Localized Relevance: Although not globally standardized like GSM, LBS remains the preferred unit in North America for paper weight measurement.

- Conversion Feasibility: Easily convertible to GSM for global comparisons, ensuring compatibility in international trade and material selection.

Understanding these attributes helps manufacturers and consumers effectively evaluate paper materials for regional and international applications, ensuring optimal quality and performance across diverse industries.

Key Differences Between GSM and LBS

The following table shows the primary differences between GSM and LBS (pounds per ream), based on their measurement systems:

| Aspect | GSM (Grams per Square Meter) | LBS (Pounds per Ream) |

|---|---|---|

| Measurement Basis | Measures the weight of a single square meter of material, providing a standardized metric. | Measures the weight of a ream (500 sheets) of paper based on its basis size, making it type-dependent. |

| Standardization | Acts as a universal standard for material weight, widely used across global industries. | Varies depending on paper type and size, predominantly used in North America. |

| Applications | Commonly used in international markets for precise material specifications in packaging, textiles, and printing. | Primarily used in North American markets for paper manufacturing, printing, and material selection. |

| Conversion | Can be converted to LBS using specific formulas based on paper type and basis size. | Can be converted to GSM for international comparison and standardization purposes. |

Understanding GSM and LBS helps manufacturers and printers select the right materials for their applications. Both units are essential for evaluating paper weight, quality, and usage suitability, whether for packaging, printing, or other industries.

GSM to LBS Conversion

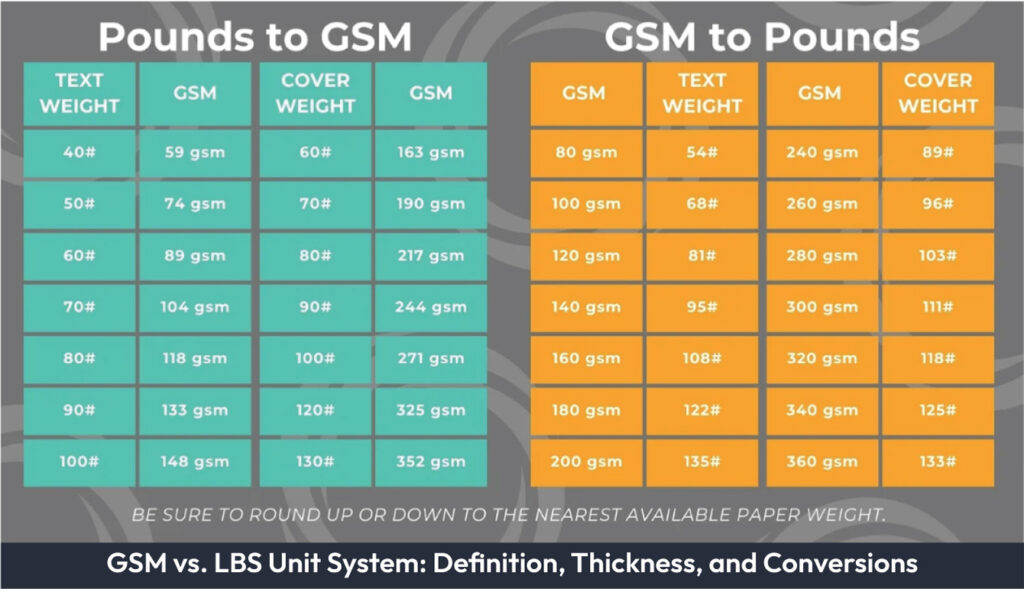

Converting between GSM and LBS requires knowledge of the paper’s basis size, as the relationship between these units is not linear across all paper types. The conversion formula for text paper is 1 GSM = 0.676 LBS (Text Paper).

Conversion Process

The step-by-step process of converting GSM to LBS is given below:

- Step 1: Identify the GSM value of the material.

- Step 2: Determine the paper type (e.g., text, bond, or cover) and its basis size.

- Step 3: Apply the appropriate conversion factor. For example, for a text paper, multiply the GSM value by 0.676 to obtain the equivalent weight in LBS.

- Printing Industry: Ensures compatibility between international and North American paper standards.

- Packaging Design: Helps manufacturers select materials with the desired thickness and durability for custom packaging.

- Book Publishing: Facilitates the selection of paper weights for different book formats, such as hardcover or paperback.

Material Thickness and Durability

Material thickness and durability are directly influenced by GSM and LBS values. Higher GSM or LBS values typically indicate thicker and more durable materials. For example:

- Textiles: Towels with a GSM of 600 are denser and more absorbent than those with a GSM of 300.

- Paper: A 100 lb cover paper is thicker and more rigid than a 20 lb bond paper, making it suitable for business cards and packaging.

What Are the Emerging Trends in GSM and LBS Usage?

The adoption of GSM and LBS in material measurement continues to evolve, driven by technological advancements, globalization, and sustainability goals. Below are some of the emerging trends shaping their usage:

- Digital Tools: Online calculators and conversion charts are increasingly used to simplify GSM-to-LBS conversions.

- Globalization: The growing need for international trade has led to greater emphasis on GSM as a universal standard.

- Sustainability: Higher GSM materials are being adopted for eco-friendly packaging solutions due to their durability and reusability.

These trends reflect the growing need for standardized, efficient, and sustainable practices in industries reliant on material measurement systems like GSM and LBS.