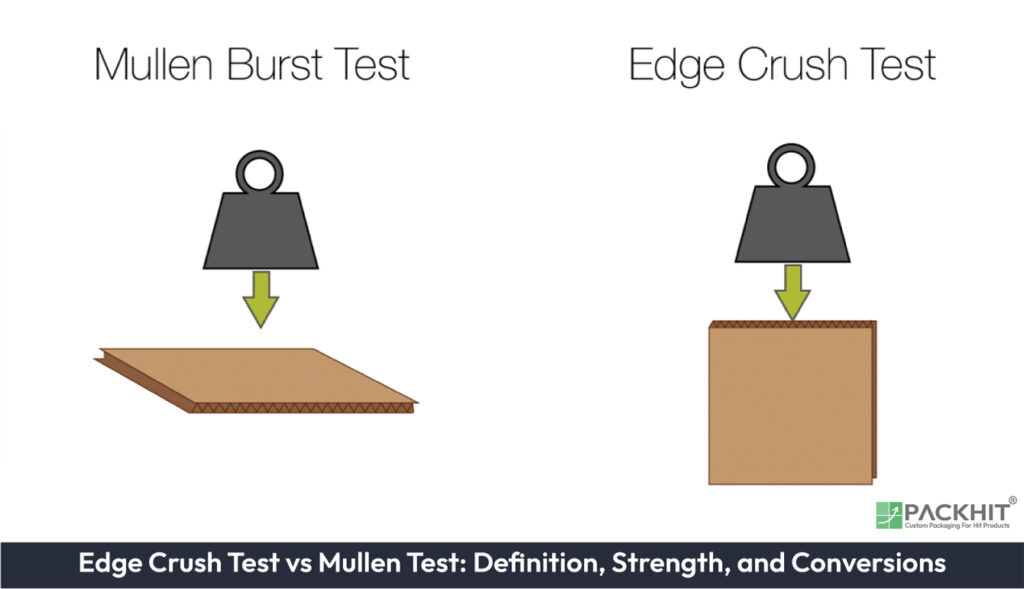

The Edge Crush Test (ECT) and Mullen Burst Test are two distinct methodologies used in the corrugated packaging industry to evaluate the strength and durability of corrugated materials. While the ECT measures the edgewise compressive strength of a corrugated board, directly correlating to its stacking performance, the Mullen Test assesses the material’s resistance to rupture under pressure, indicating its ability to withstand punctures and external forces. These tests serve different functional roles, influencing box design, material selection, and cost optimization. Understanding their mechanisms, applications, and conversion metrics is essential for manufacturers aiming to select the most suitable packaging for their products.

- What is the Edge Crush Test (ECT)?

- What is the Mullen Burst Test?

- What is the Difference between Edge Crush Test (ECT) and Mullen Test?

- How Do Conversion Metrics Relate to Edge Crush Test (ECT) and Mullen Test Ratings?

What is the Edge Crush Test (ECT)?

The Edge Crush Test (ECT) quantifies the edgewise compressive strength of corrugated board by measuring the force required to crush a small sample of the material placed vertically between two rigid plates. The result is expressed in pounds per linear inch (lb/in), commonly reported as an ECT value, such as 32 ECT. This test is directly related to the stacking strength of a box, making it a critical parameter for applications where vertical load-bearing capacity is essential.

What is the Purpose of ECT-rated Corrugated Boards?

ECT-rated corrugated boards are designed to optimize stacking performance while minimizing material usage. They are particularly suited for lightweight packaging solutions where high stacking strength is required, such as in retail and e-commerce applications. The test is widely used for single-wall, double-wall, and triple-wall corrugated boards, with variations in flute types (A, B, C, E, F) influencing the results.

What is the Mullen Burst Test?

The Mullen Burst Test measures the force required to rupture the surface of a corrugated board under pressure. The test involves applying hydraulic pressure to the material until it bursts, with results expressed in pounds per square inch (psi), such as 200 psi. This test evaluates the board’s ability to resist punctures and external forces, making it ideal for applications requiring durability during rough handling.

What is the Purpose of Mullen-rated Corrugated Boards?

Mullen-rated corrugated boards are preferred for packaging where puncture resistance and overall material integrity are critical. These boards are commonly used in industries such as food and beverage, pharmaceuticals, and heavy-duty shipping, where external impacts and internal pressure are significant concerns.

What is the Difference between Edge Crush Test (ECT) and Mullen Test?

The Edge Crush Test (ECT) and Mullen Burst Test serve distinct purposes in evaluating the strength of corrugated packaging. Below is a comparative table summarizing their key differences, applications, and implications:

| Aspect | Edge Crush Test (ECT) | Mullen Test |

|---|---|---|

| Strength Measurement | Measures edgewise compressive strength, expressed in pounds per linear inch (e.g., 32 ECT). | Measures burst strength, expressed in pounds per square inch (e.g., 200 psi). |

| Ideal Applications | Best for storage and transportation scenarios requiring high stacking performance. | Suitable for environments involving rough handling or where puncture resistance is critical. |

| Material Usage | Uses less material, optimizing for lightweight and sustainable packaging solutions. | Uses thicker material, ensuring enhanced protection for fragile or heavy items. |

| Sustainability | Eco-friendlier due to reduced raw material consumption and lighter weight. | Less sustainable due to higher material usage, though more durable for specific needs. |

| Cost Implications | Generally, more economical, with lower material and shipping costs. | Higher cost due to thicker materials and superior durability, but offsets for sensitive or high-value goods. |

| Industry Examples | Commonly used in retail and e-commerce for lightweight goods requiring efficient stacking. | Preferred in industries such as pharmaceuticals and heavy machinery, where durability and puncture resistance are vital. |

This comparison highlights the distinct advantages of each test method. While ECT is ideal for optimizing stacking strength and reducing material usage, the Mullen Test excels in scenarios requiring higher puncture resistance and durability. Understanding these differences enables manufacturers and packaging engineers to choose the most suitable testing standard based on their product type, distribution environment, and sustainability goals.

How Do Conversion Metrics Relate to Edge Crush Test (ECT) and Mullen Test Ratings?

Conversion metrics help manufacturers approximate equivalencies between Edge Crush Test (ECT) and Mullen Burst Test ratings, simplifying packaging selection based on specific performance needs such as stacking strength or puncture resistance.

Understanding Conversion Charts

Conversion charts serve as a practical tool to approximate equivalencies between Edge Crush Test (ECT) and Mullen Burst Test ratings. For instance, a 32 ECT-rated corrugated box is often aligned with a 200 Mullen-rated box in terms of general performance. These charts simplify the selection process for manufacturers by providing a comparative framework, though actual suitability depends on specific application needs.

Why are Conversion Metrics Useful?

Conversion metrics help manufacturers balance performance requirements with cost efficiency. By understanding the relationship between stacking strength and puncture resistance, businesses can determine the most appropriate packaging standard for their product’s weight, handling conditions, and shipping environment.

Limitations of Conversion Metrics

While conversion charts are beneficial, they have limitations. Factors such as flute type, board thickness, and environmental conditions can influence packaging performance, making it essential to consider these variables when selecting between ECT and Mullen ratings. Relying solely on conversion metrics without evaluating these nuances may result in suboptimal packaging solutions.

What are the Industry-Specific Use Cases for Edge Crush Test (ECT) and Mullen Test Ratings?

ECT-rated boxes are widely used in retail and e-commerce for lightweight goods requiring efficient stacking. Mullen-rated boxes are preferred in industries such as pharmaceuticals and heavy machinery, where puncture resistance and durability are paramount.

How to Choose Between the Edge Crush Test (ECT) and the Mullen Test?

Choosing between the Edge Crush Test (ECT) and the Mullen Burst Test involves evaluating key factors such as product weight, handling conditions, and distribution environment. Each test serves distinct purposes, making the decision highly dependent on the specific needs of the packaging application.

1. Product Weight

For lighter products, ECT-rated boxes provide sufficient stacking strength without excessive material usage, optimizing cost and sustainability. Conversely, heavier items or fragile goods often benefit from Mullen-rated boxes, which offer superior puncture resistance and durability.

2. Shipping Conditions

Consider the shipping and handling environment. If boxes are likely to face rough handling or external impacts during transit, Mullen-rated corrugated boards are more appropriate due to their enhanced surface durability. For controlled environments like warehouse storage, ECT-rated boxes are an economical choice due to their stacking performance.

3. Transportation Methods

Transportation methods, such as palletized shipping versus individual parcel delivery, influence the choice of test. ECT-rated boxes are ideal for palletized systems where vertical stacking strength is crucial. However, Mullen-rated boxes excel in scenarios involving frequent handling or exposure to external forces, such as courier services.

4. Cost and Sustainability Considerations

Manufacturers aiming to reduce costs and prioritize sustainability often opt for ECT-rated boxes due to their lighter weight and lower material usage. Alternatively, while Mullen-rated boxes may incur higher costs due to thicker materials, they are indispensable for high-value or sensitive products requiring maximum protection.

5. Industry-Specific Requirements

Different industries have specific packaging demands. For example, e-commerce and retail sectors typically favor ECT-rated boxes for lightweight goods, whereas industries such as pharmaceuticals and heavy machinery rely on Mullen-rated boxes to ensure puncture resistance and structural integrity.

The choice between ECT and Mullen testing standards should align with the product’s physical characteristics, the transportation process, and the manufacturer’s sustainability goals. Understanding these factors enables packaging engineers to select the most effective solution tailored to their specific requirements.