Protective packaging materials are specially designed to safeguard products during storage, transportation, and handling by providing resistance against physical impacts, environmental factors, and mishandling. These materials, ranging from paper-based options like kraft paper and corrugated cardboard to foam-based, plastic-based, and biodegradable alternatives, offer essential properties such as durability, cushioning, barrier protection, customizability, and lightweight construction. Widely used in industries such as e-commerce, food and beverage, electronics, and pharmaceuticals, protective packaging materials help reduce product damage, lower return rates, enhance customer satisfaction, and support eco-friendly practices through recyclable and compostable choices. Protective packaging materials are evolving with trends such as smart technologies, sustainable innovations, and tailored designs to meet modern industry demands.

- What is Protective Packaging Material?

- What are the Types of Protective Packaging Materials?

- 1. Paper-Based Protective Packaging

- 2. Foam-Based Protective Packaging

- 3. Plastic-Based Protective Packaging

- 4. Biodegradable and Compostable Materials

- What are the Uses of Protective Packaging Materials?

- What are the Benefits of Using Protective Packaging Materials?

- What are the Future Trends in Protective Packaging Materials?

What is Protective Packaging Material?

Protective packaging material is any material used to shield products from damage during handling, shipping, or storage. It serves as a barrier against physical, chemical, and environmental hazards. The term “protective” highlights its primary function to protect. These materials are commonly used across industries such as electronics, food and beverage, pharmaceuticals, and consumer goods.

What are the Properties of Protective Packaging Materials?

Protective packaging materials possess essential properties that make them effective in safeguarding products. These include:

- Durability: Resistance to physical stress, including compression, impact, and vibration.

- Cushioning: Shock absorption through foam or paper-based padding materials.

- Barrier Protection: Defense against environmental factors like moisture, dust, and contaminants.

- Lightweight: Reduction in shipping costs while maintaining protective effectiveness.

- Customizability: Ability to adapt to specific product dimensions and requirements.

Additionally, protective packaging materials exhibit dynamic properties that enhance their adaptability for various use cases:

- Recyclability: Many paper-based options align with eco-friendly and sustainability goals.

- Thermal Insulation: Regulation of temperature for sensitive or perishable goods.

- Anti-Static Properties: Prevention of damage to electronic components from static electricity.

- Ease of Handling: Lightweight and ergonomic designs facilitate efficient packaging operations.

What are the Types of Protective Packaging Materials?

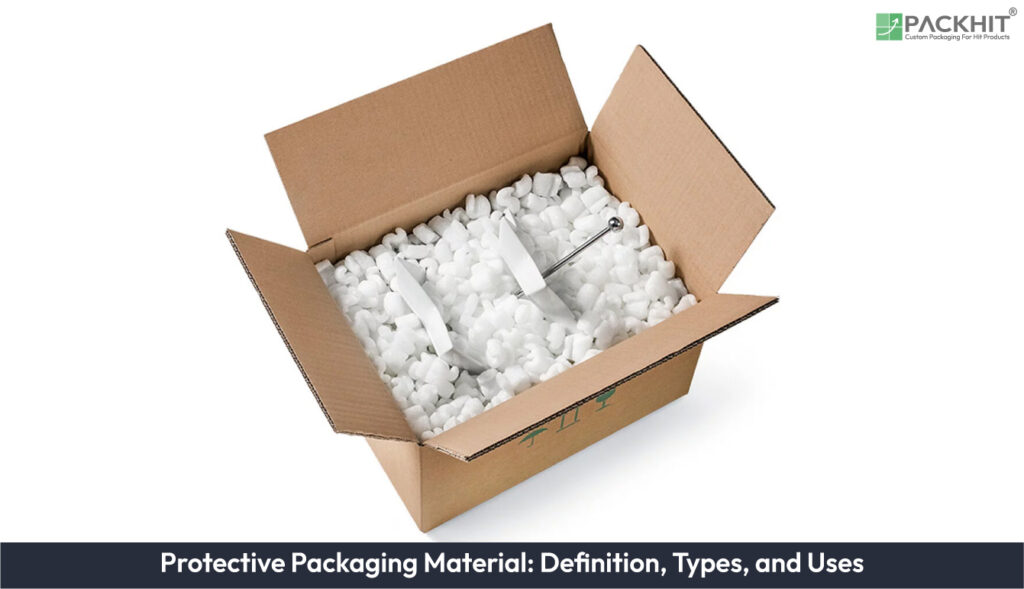

Protective packaging materials can be broadly categorized based on their composition and application. Below are the most common types:

1. Paper-Based Protective Packaging

Paper-based materials are widely used due to their sustainability and versatility. Examples include:

- Kraft Paper: A durable and recyclable material used for wrapping and void filling.

- Corrugated Cardboard: Provides structural support and cushioning for fragile items.

- Molded Pulp: Custom-shaped packaging for products like electronics and glassware.

2. Foam-Based Protective Packaging

Foam materials offer excellent cushioning and shock absorption. Common types include:

- Polyethylene Foam: Lightweight and resistant to moisture.

- Polyurethane Foam: Flexible and ideal for custom shapes.

- Expanded Polystyrene (EPS): Commonly used for insulating and protecting fragile items.

3. Plastic-Based Protective Packaging

Plastic materials are often used for their durability and barrier properties. Examples include:

- Bubble Wrap: Provides cushioning and impact resistance.

- Air Pillows: Lightweight void fillers for shipping boxes.

- Shrink Wrap: Secures items together and protects against dust and moisture.

4. Biodegradable and Compostable Materials

These materials are designed to minimize environmental impact. Examples include:

- Plant-Based Foams: Made from renewable resources like cornstarch.

- Recycled Paper: Used for void filling and wrapping.

- Compostable Films: Break down naturally in composting environments.

What are the Uses of Protective Packaging Materials?

Protective packaging materials are used across various industries to ensure product safety and quality. Key applications include:

1. E-Commerce and Retail

In e-commerce, protective packaging is essential for shipping products directly to consumers. Materials like corrugated cardboard and air pillows are commonly used to prevent damage during transit.

2. Food and Beverage

Thermal insulation and moisture-resistant materials are critical for preserving the freshness and quality of perishable goods. Examples include insulated liners and molded pulp trays.

3. Electronics

Anti-static and shock-absorbing materials are used to protect sensitive electronic components. Foam inserts and custom-molded pulp are popular choices.

4. Pharmaceuticals

Protective packaging ensures the integrity of medical products during transportation. Temperature-controlled packaging and tamper-evident seals are commonly used.

What are the Benefits of Using Protective Packaging Materials?

The use of protective packaging materials offers several advantages for manufacturers and consumers:

- Product Safety: Reduces the risk of damage during transit.

- Cost Efficiency: Minimizes returns and replacements due to damaged goods.

- Customer Satisfaction: Ensures products arrive in pristine condition.

- Environmental Sustainability: Recyclable and biodegradable options reduce environmental impact.

What are the Future Trends in Protective Packaging Materials?

The protective packaging industry is evolving to meet changing consumer demands and environmental regulations. Emerging trends include:

- Sustainable Materials: Increased use of biodegradable and recyclable materials.

- Smart Packaging: Integration of sensors to monitor temperature and humidity.

- Lightweight Designs: Reducing material usage while maintaining protective qualities.

- Customization: Tailored solutions for specific product requirements.

Protective packaging materials are indispensable for manufacturers aiming to deliver products safely and efficiently. By understanding the types, properties, and applications of these materials, businesses can make informed decisions to enhance product protection, reduce costs, and align with sustainability goals. As the industry continues to innovate, the future of protective packaging promises even greater efficiency and environmental responsibility.