Debossing packaging is a specialized printing technique that involves creating recessed designs or logos on the surface of packaging materials. Core characteristics of debossing include its tactile feel, suitability for durable materials, and potential for customization. The process uses a metal die and is widely adopted in industries such as luxury products, corporate materials, retail, food and beverages, tech, and wedding invitations. The advantages of debossing include aesthetic appeal, brand differentiation, durability, versatility, consumer engagement, and sustainability. However, it faces challenges like material limitations, cost, and design complexity. Compared to embossing, debossing is more subtle and cost-effective. Emerging trends highlight eco-friendly materials, combination techniques, and minimalist designs.

- What is Debossing in Packaging?

- How Does Debossing Work?

- What are the Benefits of Debossing in Packaging?

- Enhanced Aesthetic Appeal

- Brand Differentiation

- Durability

- Versatility

- Consumer Engagement

- Sustainability Options

- Which Industries Use Debossing in Packaging?

- 1. Luxury Product Packaging

- 2. Corporate and Promotional Materials

- 3. Custom Packaging for Retail

- 4. Food and Beverage Industry

- 5. Tech and Electronics Packaging

- 6. Wedding Invitations

- What are the Challenges and Limitations of Debossing?

- Comparative Analysis of Debossing vs. Embossing

- Emerging Trends in Debossing Packaging

What is Debossing in Packaging?

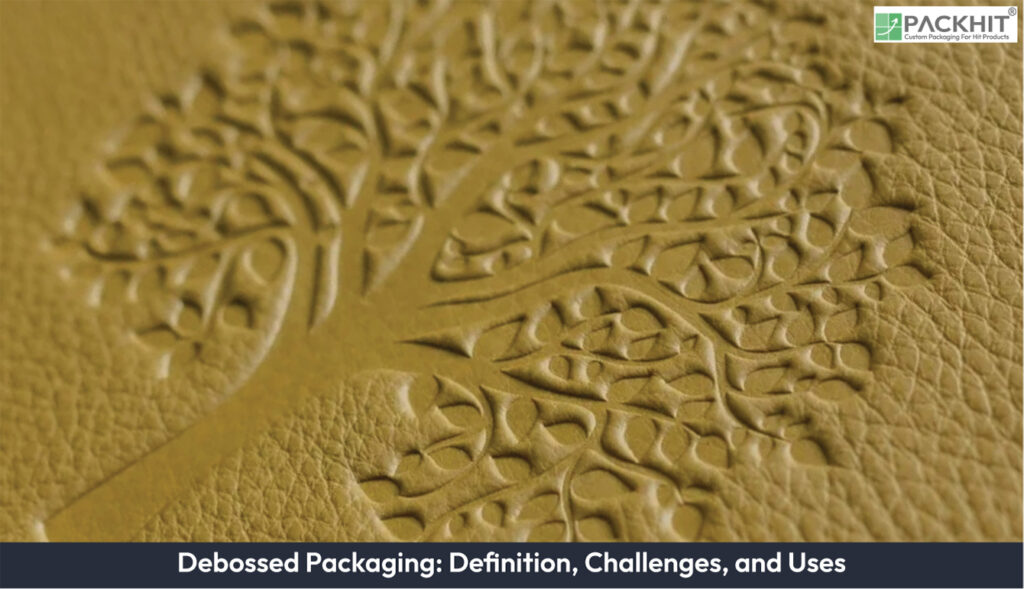

Debossing in packaging refers to the process of pressing a design, logo, or text into the surface of a material using a metal die. Unlike embossing, which raises the design above the surface, debossing creates a sunken or recessed effect. This technique is often employed to convey sophistication, precision, and understated elegance in product presentation.

Core Characteristics of Debossing

The core characteristics of debossing are mentioned below:

- Texture: Features a recessed and indented surface, offering a refined tactile interaction that enhances user engagement.

- Design Type: Exhibits sunken patterns, logos, or text, emphasizing subtlety and sophistication over boldness.

- Material Suitability: Best suited for dense and durable materials such as cardboard, paperboard, and leather, ensuring the design remains intact and visually appealing.

- Durability: Provides long-lasting aesthetic quality by resisting wear and tear, making it ideal for products requiring sustained visual impact.

- Customization Potential: Allows integration with additional techniques, including foil stamping or lamination, to further elevate the packaging’s premium feel.

How Does Debossing Work?

The debossing process involves the use of a steel or metal die, which is pressed into the surface of the packaging material. This creates an indented design that is both visually appealing and tactilely engaging. The process can be enhanced with additional techniques such as foil stamping or matte lamination to achieve a more luxurious finish.

What are the Benefits of Debossing in Packaging?

Debossing offers several benefits that make it a preferred choice for custom packaging. The benefits of debossing in packaging are given below:

Enhanced Aesthetic Appeal

Debossing creates controlled depth and shadow, producing visible contrast and surface texture. Designs range from shallow recesses (fractions of a millimeter) to deeper impressions (around 1 mm), which change how light reveals detail. Uncoated and matte stocks show the effect most clearly, while ink filling or selective varnish can add targeted color or gloss inside the recess.

Brand Differentiation

Debossed logos and marks separate a product visually and tactually from printed-only packaging. Use blind deboss for restraint, or combine deboss with foil or spot coatings to direct attention to specific elements. Limited-edition numbering or subtle pattern debosses help convey product editions and authenticity.

Durability

Indented designs resist surface abrasion that removes printed ink, so the mark remains readable after handling and transit. Pressing compresses fibers in thicker stocks rather than removing material, which helps the impression survive scuffs and light crushing over time.

Versatility

Debossing works with printed graphics, foil stamping, spot UV, and laminations to create layered effects. You can ink-fill the recess for contrast, register printed artwork to the impression, or use negative-space patterns for texture without extra materials. Tooling and setup vary by run size, so choose the combination that matches production volume and budget.

Consumer Engagement

Tactile marks invite handling and increase the time a shopper inspects the package. That extra handling can improve recognition of brand marks and printed details, making the packaging more memorable on the shelf or at the point of unboxing.

Sustainability Options

Debossing works on recyclable stocks such as recycled paperboard, kraft board, and FSC-certified uncoated paper. When used without metallic foils or plastic laminates, debossing makes the pack easier to recycle. Metal dies are reusable across multiple runs, which spreads their embodied energy over large volumes and reduces per-unit tooling impact.

Which Industries Use Debossing in Packaging?

Debossing is a popular technique across several industries due to its ability to enhance branding and product presentation. Here are the industries that most commonly utilize debossing in their packaging:

1. Luxury Product Packaging

Debossing is frequently used in luxury product packaging to create a premium and sophisticated look. High-end brands often use this technique for packaging perfumes, jewelry, and cosmetics, as it conveys exclusivity and attention to detail.

2. Corporate and Promotional Materials

Corporate branding materials, such as business card holders, gift boxes, and promotional kits, often feature debossed logos or designs. This adds a professional and refined touch, enhancing the perceived value of the items.

3. Custom Packaging for Retail

Retailers use debossing to create unique and memorable packaging for their products. This technique is particularly effective for limited-edition items, gift sets, and seasonal packaging, where differentiation is key.

4. Food and Beverage Industry

In the food and beverage sector, debossing is utilized to elevate the visual appeal of premium products such as artisanal chocolates, luxury wine bottles, and specialty food boxes. The tactile element reinforces the perception of quality and exclusivity.

5. Tech and Electronics Packaging

Tech companies often incorporate debossing into their product packaging to highlight innovation and sophistication. Items like smartphone boxes, high-end gadget cases, and premium accessory packaging commonly feature debossed logos or patterns.

6. Wedding Invitations

Debossing is a favored technique for wedding invitations, offering a touch of sophistication and elegance. The recessed designs create a memorable tactile experience, making these invitations stand out as keepsakes for guests.

What are the Challenges and Limitations of Debossing?

While debossing offers numerous advantages, it also comes with certain challenges and limitations, given below:

Material Suitability

Debossing is less effective on thin or flexible materials, as the process requires a certain level of thickness to achieve the desired depth and durability. Materials like thin paper or plastic may not hold the indented design well.

Cost Implications

The use of custom metal dies and the precision required in the debossing process can increase production costs. This makes it a less cost-effective option for large-scale or budget-conscious projects.

Design Complexity

Highly intricate designs may not translate well into debossed patterns, as the level of detail can be lost during the pressing process. Simplified designs are often more effective.

Comparative Analysis of Debossing vs. Embossing

Debossing and embossing are two techniques that are often juxtaposed due to their similar processes, but they differ significantly in the outcomes they deliver.

Debossing involves pressing a design into the material to create a recessed effect, while embossing raises the design above the surface for a prominent, elevated appearance

The table below provides a comparative analysis of debossing and embossing:

| Feature | Debossing | Embossing |

|---|---|---|

| Texture | Recessed | Raised |

| Visual Impact | Subtle and understated | Bold and prominent |

| Material Suitability | Thicker materials | Works on a wider range of materials |

| Cost | Lower than embossing | Higher due to additional layers |

As shown in the table above, this side-by-side comparison highlights the key attributes of each technique, offering a clear perspective on their respective strengths and applications. By evaluating factors like texture, visual impact, material compatibility, and cost, manufacturers can make informed decisions to align their packaging strategies with their brand’s goals and market positioning.

Emerging Trends in Debossing Packaging

As consumer preferences evolve, debossing continues to adapt to meet new demands. Some of the emerging trends include:

- Eco-Friendly Materials: Using sustainable and recyclable materials for debossed packaging to align with environmental concerns.

- Combination Techniques: Pairing debossing with matte lamination, foil stamping, or UV coating for a multi-dimensional effect.

- Minimalist Designs: Leveraging the subtlety of debossing to create clean, minimalist packaging that resonates with modern aesthetics.