Corrugated fiberboard, often referred to as corrugated cardboard, is a versatile packaging material characterized by its fluted corrugated sheet and one or two flat linerboards. Known for its durability, lightweight nature, and eco-friendly properties, it is widely used in packaging, shipping, and crafting applications.

What is Corrugated Fiberboard?

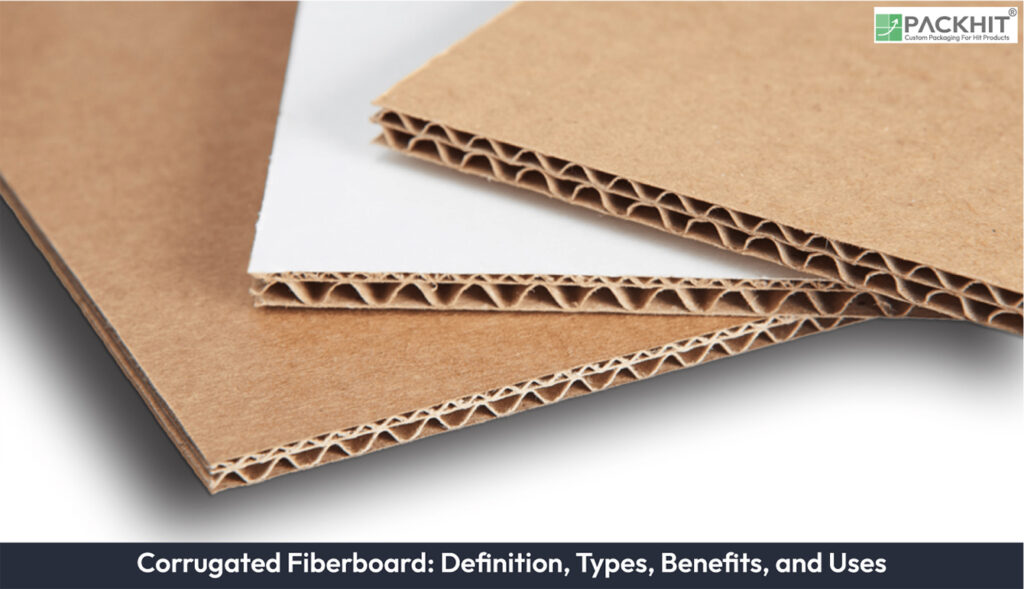

Corrugated fiberboard is a type of fiberboard commonly used for packaging and construction. It is composed of a fluted corrugated sheet bonded to one or two flat linerboards, creating a durable and lightweight material. The corrugated structure enhances its strength, making it suitable for protecting goods during transportation and storage.

What are the components of Corrugated Fiberboard?

Corrugated fiberboard consists of two primary components:

- Linerboard: Flat sheets of containerboard that provide structural integrity and aesthetic appeal.

- Medium: The fluted layer that offers cushioning and compressive strength.

Material

Both the linerboard and medium are made from containerboard, a heavy-duty paper material. This composition ensures the fiberboard is strong, durable, and suitable for various packaging applications.

Fluting

The fluted layer, often referred to as the “medium,” is a wavy texture that provides structural integrity and cushioning. Different flute types, such as C flute, E flute, and B flute, offer varying levels of thickness and durability, catering to specific packaging needs.

What are the Types of Corrugated Fiberboard?

Corrugated fiberboard is available in a variety of types mentioned below:

Single-Wall

Single-wall corrugated fiberboard consists of one row of fluted paper sandwiched between two linerboards. It is suitable for lightweight and general-purpose applications.

Double-Wall

Double-wall corrugated fiberboard features two rows of fluted paper and three linerboards. This type provides enhanced strength and is ideal for heavier goods.

Triple-Wall

Triple-wall corrugated fiberboard includes three rows of fluted paper and four linerboards. It is the most durable option, often used for industrial containers and heavy-duty applications.

Flute Types

Corrugated fiberboard is available in various flute types, including:

- C Flute: Offers a balance between cushioning and strength, commonly used for shipping boxes.

- E Flute: Thinner and more compact, ideal for retail packaging and printing.

- B Flute: Provides excellent stacking strength and crush resistance, suitable for heavy items.

What are the Benefits of Corrugated Fiberboard?

Corrugated fiberboard has multiple benefits, including durability, lightweight construction, eco-friendliness, customizability, and cost-effectiveness.

Durability

Corrugated fiberboard is highly durable, offering resistance to compressive stacking loads and external pressures. Its corrugated structure ensures longevity and reliability in packaging applications.

Lightweight

Despite its strength, corrugated fiberboard is lightweight, reducing shipping and storage costs. This feature makes it a cost-effective choice for manufacturers and logistics providers.

Eco-Friendliness

Made from recycled kraft paper and fully recyclable, corrugated fiberboard promotes sustainable packaging practices. It has a recovery rate of 93%, making it the most recycled packaging material globally.

Customizability

Corrugated fiberboard is highly customizable, allowing manufacturers to tailor designs, dimensions, and printing options to meet specific branding and product requirements.

Cost-Effectiveness

Corrugated fiberboard is an affordable packaging solution, offering lower production costs compared to alternative materials like plastic or wood.

What are the uses of Corrugated Fiberboard?

Corrugated fiberboard is used in various industries for packaging, shipping, retail displays, crafting, and construction due to its strength, versatility, and protective properties.

Packaging

Corrugated fiberboard is widely used for packaging goods across industries. Its durability and cushioning properties make it ideal for shipping boxes, retail packaging, and protective containers.

Shipping

Corrugated fiberboard is essential for shipping goods, providing protection against shocks, scratches, and stacking loads. It is commonly used for transporting electronics, machinery, and consumer goods.

Retail Displays

Point-of-purchase (POP) displays made from corrugated fiberboard enhance product visibility in retail environments. These displays are lightweight, customizable, and eco-friendly.

Crafting

Corrugated fiberboard is used in crafting applications, such as creating decorations, gift boxes, and scrapbooking materials. Its durability and aesthetic appeal make it a popular choice among hobbyists.

Construction

Corrugated fiberboard is employed in construction for covering furniture, floors, and walls during renovation works. Its protective properties prevent damage from paint, tiling, and other construction activities.

How Does Corrugated Fiberboard Contribute to Sustainability and Recycling?

Corrugated fiberboard plays a significant role in sustainable packaging practices due to its high recyclability and eco-friendly properties. It is predominantly made from recycled paper materials, and its recycling process ensures minimal environmental impact.

Recyclability

Corrugated fiberboard is fully recyclable, with a recovery rate of 93%, making it one of the most recycled packaging materials worldwide. The recycling process involves collecting, sorting, shredding, and reprocessing the material into new products, significantly reducing waste.

Environmental Impact

Most corrugated fiberboard is composed of 70% to 100% recycled content, minimizing its ecological footprint. By promoting the use of renewable resources and reducing dependency on virgin materials, corrugated fiberboard supports global sustainability efforts.

Reusability

Designed for repeated use, corrugated fiberboard can be collapsed and reused for various applications, enhancing both its environmental and economic appeal. This durability and versatility make it an ideal choice for manufacturers and consumers aiming to reduce packaging waste.