Reusable packaging refers to durable containers, crates, pallets, and materials designed for repeated use across supply chains, offering an eco-friendly alternative to single-use packaging. It plays a key role in reducing waste, conserving resources, and lowering carbon emissions, especially in industries like food, retail, healthcare, and logistics. Though it demands higher upfront investment, reusable packaging delivers long-term savings, waste management benefits, and operational efficiencies. These systems work through a closed-loop process involving collection, cleaning, inspection, and redistribution, often aided by RFID and tracking tech.

Common types of reusable packaging include RPCs, reusable pallets, totes, heavy-duty bags, and reinforced paperboard, each tailored to specific industry needs. However, implementation faces challenges like high initial costs, complex logistics, hygiene compliance, and consumer awareness. Despite these hurdles, future trends point to greater adoption through smart technologies, regulatory support, and broader applications in sectors like e-commerce and healthcare.

- What is Reusable Packaging?

- Why Does Reusable Packaging Matter?

- 1. Cost Efficiency

- 2. Waste Management Savings

- 3. Operational Optimization

- 4. Carbon Emission Reduction

- 5. Resource Conservation

- 6. Waste Prevention

- How Does Reusable Packaging Work?

- Deployment and Collection

- Cleaning and Maintenance

- Inspection and Quality Assurance

- Redistribution and Tracking

- What are the Different Types of Reusable Packaging and their Industry Applications?

- Reusable plastic containers and RPCs

- Reusable pallets and skids

- Shipping totes and nestable bins

- Reusable bags and heavy-duty sacks

- Returnable paperboard and reinforced paper systems

- Challenges in Implementing Reusable Packaging

- Future Trends in Reusable Packaging

What is Reusable Packaging?

Reusable packaging is defined as packaging designed to be used multiple times, extending its lifecycle and reducing the need for disposable alternatives. It is typically constructed from durable materials such as high-density polyethylene (HDPE), polypropylene, stainless steel, or treated cardboard, which are capable of withstanding repeated handling, cleaning, and transportation. Unlike single-use packaging, reusable packaging is integrated into systems that facilitate its return, inspection, and reuse, ensuring its functionality over extended periods.

Why Does Reusable Packaging Matter?

Reusable packaging is a critical solution to mitigate environmental challenges arising from excessive waste and resource depletion. Packaging waste constitutes approximately 30% of municipal solid waste globally, underscoring the urgent need for sustainable alternatives. By adopting reusable packaging, businesses can significantly lower their ecological footprint, reduce costs, and contribute to the circular economy by promoting material recovery and reuse.

1. Cost Efficiency

Reusable packaging systems, despite requiring higher upfront investment, deliver significant long-term savings. Businesses can amortize production costs over multiple usage cycles, reducing the overall cost per use compared to disposable packaging. Additionally, lower replacement rates due to durability further enhance cost-effectiveness.

2. Waste Management Savings

By minimizing single-use materials, reusable packaging reduces waste disposal and recycling expenses, while also alleviating pressure on waste management infrastructure. These systems divert materials from landfills and incinerators, significantly lowering environmental impact and operational costs. They foster a cleaner environment by promoting efficient resource utilization and reducing the volume of discarded packaging waste.

3. Operational Optimization

Standardized, durable packaging designs streamline logistics by preventing product damage during transportation. Features such as stackability and ergonomic designs enhance efficiency, reducing handling time and replacement expenses while ensuring smoother operations across supply chains.

4. Carbon Emission Reduction

Reusable packaging significantly lowers greenhouse gas emissions compared to single-use alternatives. For instance, reusable plastic containers (RPCs) used in the food industry can achieve up to a 60% reduction in carbon emissions, contributing to sustainable practices and climate change mitigation.

5. Resource Conservation

By curbing demand for raw materials like paper, plastic, and metals, reusable packaging reduces resource extraction and manufacturing impacts. This conservation supports environmental sustainability while lowering production costs tied to material procurement.

6. Waste Prevention

The extended lifecycle of reusable packaging significantly reduces the volume of waste entering municipal systems, alleviating pressure on waste management infrastructure. Additionally, this reduction fosters cleaner environments and improves resource utilization efficiency across industries, promoting sustainable operational practices.

How Does Reusable Packaging Work?

Reusable packaging systems function through a structured closed-loop process designed to maximize efficiency and sustainability. This process includes deployment, collection, cleaning, inspection, and redistribution, ensuring the packaging remains functional across multiple use cycles. Advanced tracking technologies, such as RFID tags and QR codes, play a pivotal role in monitoring the lifecycle of packaging, enhancing management efficiency, reducing losses, and supporting circular economy practices.

Deployment and Collection

The lifecycle begins with the deployment of reusable packaging to end-users, such as manufacturers, retailers, or logistics providers. After fulfilling its purpose, the packaging is collected through reverse logistics systems that optimize transportation routes to reduce collection costs and environmental impact. These systems ensure the timely return of used packaging to processing facilities for further handling.

Cleaning and Maintenance

Once collected, reusable packaging undergoes thorough cleaning and maintenance to preserve its durability and usability. Automated cleaning systems equipped with advanced sensors detect contamination and ensure hygienic handling, especially for industries with stringent safety requirements, such as food and healthcare. Regular maintenance further extends the lifecycle of the packaging.

Inspection and Quality Assurance

Inspection processes assess the structural integrity of reusable packaging to identify damage or wear. Automated quality assurance systems often use AI technologies to streamline inspections, ensuring that only fully functional packaging is redistributed for reuse. This step minimizes the risk of operational disruptions and maintains product safety.

Redistribution and Tracking

After cleaning and inspection, reusable packaging is redistributed to users for subsequent applications. Tracking technologies, such as RFID or QR codes, facilitate real-time monitoring of packaging location, usage frequency, and condition. These tools enable businesses to optimize inventory management and prevent losses, ensuring seamless integration into supply chains.

What are the Different Types of Reusable Packaging and their Industry Applications?

Reusable packaging comes in various forms, each suited to specific industries and supply chain needs. Below are five common types along with their typical uses:

Reusable plastic containers and RPCs

Reusable plastic containers provide repeat transport for fresh produce, meat, dairy, and bulk components. Manufacturers use HDPE or polypropylene crates for stacked transport and automated handling. Examples include harvest crates for apples and RPCs for dairy trays. Companies run closed loops with cleaning stations and RFID tracking to lower per-use cost and reduce breakage.

Reusable pallets and skids

Reusable pallets carry heavier loads in warehousing and cross-dock operations. Firms choose plastic or metal pallets for washability and consistent dimensions. Examples include plastic pallets for food lines and metal skids in automotive plants. Standardized pallet sizes reduce handling time and damage across forklifts and conveyors.

Shipping totes and nestable bins

Shipping totes streamline order fulfillment in e-commerce and retail distribution centers. Totes often stack, nest, or fold to save space between cycles. Examples include stackable pick totes for online orders and collapsible totes for third-party logistics. Businesses route empty totes back through reverse logistics for inspection and reuse.

Reusable bags and heavy-duty sacks

Reusable bags transport bulk goods and consumer purchases from the store to the home. Manufacturers select woven polypropylene, canvas, or coated fabrics for tensile strength and washability. Examples include reusable grocery bags for retail chains and bulk grain sacks in industrial supply. Labels and simple return points increase recovery rates.

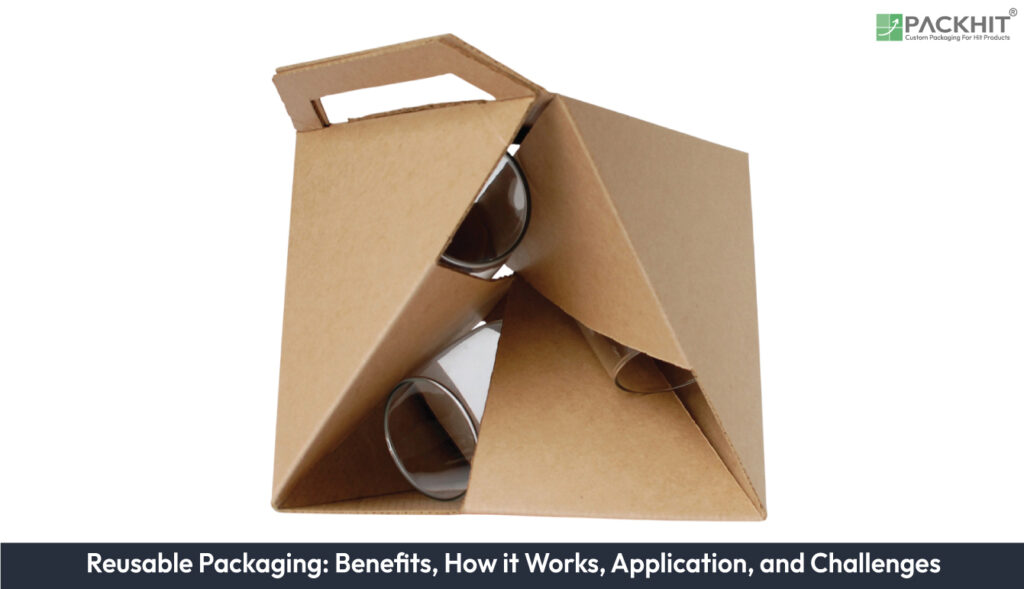

Returnable paperboard and reinforced paper systems

Returnable paperboard systems provide a lower-weight option for repeated parcel and display use. Producers use laminated or reinforced corrugated board and water-resistant treatments to extend cycle life. Examples include reinforced mailers for direct-to-consumer returns and reusable corrugated trays for packaged parts in light manufacturing. These solutions reduce fiber demand while fitting existing recycling streams when retired.

Challenges in Implementing Reusable Packaging

The challenges involved in implementing reusable packaging are outlined below:

- Economic barriers: Higher upfront capital for durable materials like HDPE crates and polypropylene totes, and for centralized cleaning equipment and tracking systems, raises initial project cost. Small and medium-sized enterprises face longer payback periods and tighter cash flow.

- Logistical complexity: Programs require reverse logistics for collection, sorting, cleaning, inspection, and return. Coordinating these steps across multi-site or cross-border supply chains increases transit time and handling costs.

- Consumer education: Low awareness of return procedures and incentives reduces return rates. Clear labeling, point of sale instructions, and simple return flows are necessary to recover units from end users.

- Hygiene and safety: Food-grade and healthcare-grade reuse demand validated cleaning protocols, microbiological monitoring, and traceable recordkeeping. Added labor, water, and energy for sanitation increases the per-cycle operating cost.

- Scalability limitations: Scaling requires processing capacity, transport frequency, and inventory buffers. Smaller operators face higher per-unit processing costs and limited access to shared cleaning infrastructure.

- Regulatory compliance: Varying regional rules on material reuse traceability and safety require testing documentation and legal review. Compliance increases administrative burden and time to market.

Future Trends in Reusable Packaging

The adoption of reusable packaging is expected to grow as industries increasingly prioritize sustainability. Innovations such as smart packaging equipped with IoT sensors and blockchain-based tracking systems are enhancing the efficiency and transparency of reusable packaging systems. Additionally, regulatory frameworks promoting extended producer responsibility (EPR) are driving businesses to invest in sustainable packaging solutions.

Emerging Applications

Reusable packaging is expanding into new domains, including e-commerce, where durable mailers and shipping boxes are gaining traction. Similarly, industries such as healthcare and electronics are exploring reusable solutions to reduce waste and improve cost efficiency.

Policy and Regulation

Governments worldwide are implementing policies to encourage the use of reusable packaging. For instance, the European Union’s Packaging and Packaging Waste Directive mandates increased reuse and recycling rates, fostering innovation in sustainable packaging systems.