Life Cycle Assessment (LCA) in packaging involves a comprehensive evaluation of the environmental impacts across the entire lifecycle of packaging materials, including raw material extraction, production, usage, and end-of-life management. It quantifies metrics such as carbon emissions, energy consumption, water usage, waste generation, resource depletion, ecotoxicity, pollution, and biodiversity impact to guide manufacturers toward sustainable decisions. Life Cycle Assessment (LCA) follows a structured process comprising goal and scope definition, inventory analysis, impact assessment, and interpretation, enabling informed choices in material selection, design optimization, regulatory compliance, consumer engagement, supply chain efficiency, circular economy integration, and corporate sustainability reporting. Despite challenges like data availability, methodological variability, scope limitations, and cost constraints, advancements in LCA software, regional customization, real-time monitoring, and integration of social metrics are driving its adoption. As sustainability trends evolve, LCA empowers manufacturers to balance functionality, cost-efficiency, and environmental stewardship, positioning them as leaders in sustainable packaging innovation.

- What is Life Cycle Assessment (LCA)?

- What are the Stages of a Packaging Life Cycle Assessment?

- How Does the Life Cycle Assessment (LCA) Process Work?

- Why is Life Cycle Assessment Important in Packaging?

- What are the Environmental Impacts of Packaging Assessed by Life Cycle Assessment (LCA)?

- Carbon Emissions

- Energy Consumption

- Water Usage

- Waste Generation

- Resource Depletion

- Ecotoxicity and Pollution

- Biodiversity Impact

- Applications of Life Cycle Assessment in Packaging

- Challenges and Limitations of Life Cycle Assessment

- Emerging Trends in Life Cycle Assessment for Packaging

What is Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) is defined as a methodology for quantifying the environmental impacts of a product, process, or service across its entire lifecycle. This lifecycle encompasses raw material extraction, manufacturing, distribution, usage, and end-of-life management, including disposal or recycling. The primary objective of LCA is to provide a detailed understanding of the environmental burdens associated with each stage, enabling stakeholders to identify opportunities for improvement and minimize ecological harm.

In packaging, LCA evaluates the environmental performance of materials such as paper, plastic, glass, and metal, considering factors like energy consumption, greenhouse gas emissions, water usage, and waste generation. By integrating quantitative metrics, LCA facilitates comparisons between packaging alternatives, guiding manufacturers toward more sustainable choices.

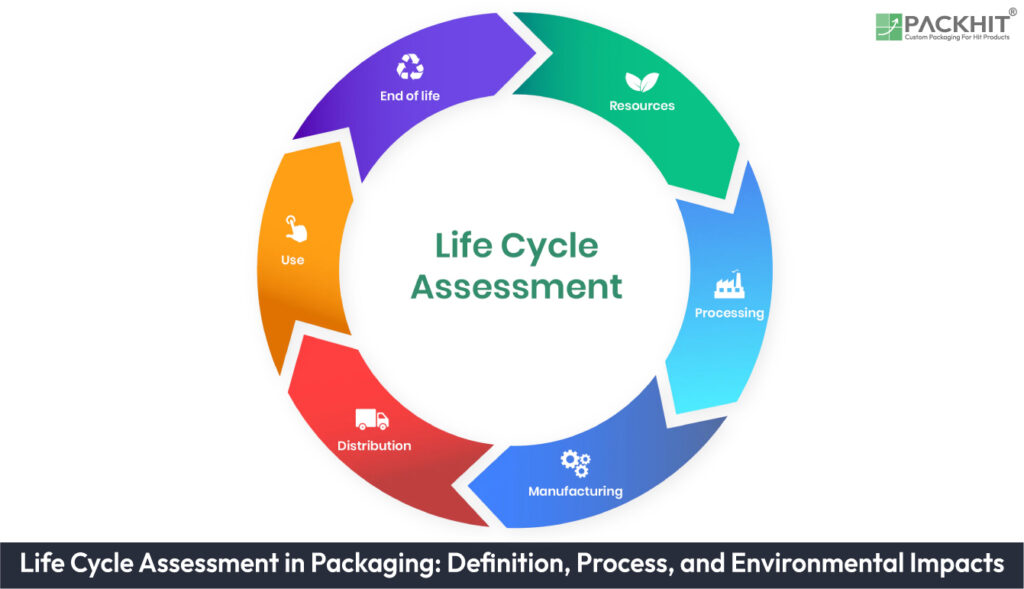

What are the Stages of a Packaging Life Cycle Assessment?

The stages of a Packaging Life Cycle Assessment (LCA) include raw material extraction, production, usage, and end-of-life management, each systematically analyzed to evaluate environmental impacts across the lifecycle of packaging materials.

1. Raw Material Extraction

The first stage of LCA involves assessing the environmental impacts of extracting raw materials used in packaging production. For paper-based packaging, this includes the harvesting of wood or other cellulose sources, as well as the energy and water required for pulp processing. Key metrics include deforestation rates, carbon emissions, and resource depletion.

2. Production

The production stage examines the environmental footprint of converting raw materials into finished packaging products. This includes energy-intensive processes such as paper milling, printing, and coating. Metrics such as energy consumption, chemical usage, and waste generation are analyzed to identify areas for efficiency improvement.

3. Usage

During the usage phase, LCA evaluates the environmental impact of packaging as it fulfills its functional role, such as protecting goods during transportation or storage. Factors like durability, reusability, and consumer behavior (e.g., recycling rates) are considered to assess the lifecycle performance of the packaging.

4. End-of-Life Management

The final stage focuses on the disposal or recycling of packaging materials. Paper-based packaging, for instance, is often recyclable, but the environmental benefits depend on the efficiency of recycling systems and the contamination levels of waste streams. Metrics such as landfill diversion rates, energy recovery, and material degradation are critical in this phase.

How Does the Life Cycle Assessment (LCA) Process Work?

The Life Cycle Assessment (LCA) process is structured into four key phases: goal and scope definition, inventory analysis, impact assessment, and interpretation. Each phase is designed to systematically evaluate the environmental performance of a product or service.

Goal and Scope Definition

This phase establishes the objectives of the LCA study and defines the boundaries of the analysis. For packaging, the scope may include specific material types, geographic regions, or lifecycle stages. Clear goals ensure that the study addresses relevant environmental concerns and provides actionable insights.

Inventory Analysis

Inventory analysis involves collecting data on inputs (e.g., raw materials, energy) and outputs (e.g., emissions, waste) for each lifecycle stage. For paper-based packaging, this includes quantifying water usage, energy consumption, and chemical emissions during production and recycling.

Impact Assessment

In this phase, the environmental impacts of the inventory data are evaluated using standardized metrics such as global warming potential (GWP), acidification potential, and resource depletion. This step translates raw data into meaningful indicators of ecological harm.

Interpretation

The final phase involves analyzing the results to identify opportunities for reducing environmental impacts. For packaging manufacturers, this may include switching to renewable materials, optimizing production processes, or improving recycling systems.

Why is Life Cycle Assessment Important in Packaging?

Life Cycle Assessment (LCA) is essential for packaging manufacturers aiming to balance functionality with sustainability. By providing a comprehensive evaluation of environmental impacts, LCA enables informed decision-making that reduces ecological harm while maintaining product performance. Key benefits include:

- Identifying high-impact lifecycle stages for targeted improvements.

- Comparing alternative materials and designs to select the most sustainable options.

- Enhancing compliance with environmental regulations and certifications.

- Supporting corporate sustainability goals and consumer demand for eco-friendly products.

What are the Environmental Impacts of Packaging Assessed by Life Cycle Assessment (LCA)?

Life Cycle Assessment (LCA) evaluates the environmental impacts of packaging across its entire lifecycle, offering a detailed examination of resource use, emissions, and waste generation. These impacts are assessed using specific metrics to guide sustainable decision-making.

Carbon Emissions

Carbon emissions quantify greenhouse gas mass at each lifecycle stage (e.g., CO2, CH4, N2O). LCA reports this as kg CO2‑equivalent per functional unit to locate hotspots in raw material sourcing, production, transport, and disposal. Mitigation options include switching to low‑carbon energy, substituting lower‑impact materials, and reducing transport distances.

Energy Consumption

Energy consumption measures total primary energy used across the lifecycle (electricity, process heat, diesel). LCA expresses energy in MJ or kWh per functional unit and highlights high‑use steps such as pulping, drying, and coating. Actions to cut energy include heat recovery, process optimization, and onsite renewable electricity generation.

Water Usage

Water usage totals freshwater withdrawals and process water across stages (e.g., pulping, bleaching, cooling). LCA reports water in m3 per tonne or per functional unit and flags stages with high withdrawals or effluent loads. Closed‑loop process water, optimized bleaching chemistry, and filtration reduce freshwater demand and effluent volume.

Waste Generation

Waste generation covers production scraps, offcuts, post‑consumer packaging, and landfill inputs. LCA quantifies mass flows and diversion rates to assess material recovery potential. Improving sortation, reducing contamination, and designing for recyclability increase recovered material and lower landfill contributions.

Resource Depletion

Resource depletion measures use of non‑renewable and renewable inputs (e.g., fossil fuels, minerals, timber). LCA tallies primary material demand and identifies dependence on virgin feedstocks. Substituting recycled content, sourcing certified timber, and reducing material intensity lowers pressure on finite resources.

Ecotoxicity and Pollution

Ecotoxicity quantifies chemical impacts on soil, freshwater, and marine life from emissions and effluents (e.g., bleaches, inks, coating solvents). LCA converts emissions into toxicity indicators to compare risks. Substituting lower‑toxicity chemistries, installing effluent treatment, and controlling particulate emissions cut ecological harm.

Biodiversity Impact

Biodiversity impact measures habitat loss, land‑use change, and species risk tied to raw material extraction (e.g., deforestation for timber). LCA uses land‑use and species threat indicators to reveal impacts per functional unit. Using recycled fibers, sourcing from certified forests, and reducing land use intensity lowers biodiversity losses.

Applications of Life Cycle Assessment in Packaging

Life Cycle Assessment (LCA) serves as a foundational tool for achieving sustainability goals in the packaging industry. Its applications span multiple aspects of design, production, and performance optimization, enabling manufacturers to make data-driven decisions that minimize environmental impacts. Key applications include:

- Material Selection: LCA provides a comparative analysis of materials such as paper, plastic, glass, and metal, allowing manufacturers to identify options with lower environmental footprints. For example, paper-based packaging often emerges as a favorable choice due to its recyclability and renewable sourcing.

- Design Optimization: By evaluating lifecycle metrics, manufacturers can refine packaging designs to reduce material consumption, enhance durability, and improve end-of-life recyclability. Techniques such as lightweighting and modular design are commonly employed to achieve these goals.

- Regulatory Compliance: LCA supports adherence to environmental standards and certifications, including ISO 14040 and cradle-to-cradle frameworks. These guidelines help manufacturers align with global sustainability mandates and avoid regulatory penalties.

- Consumer Engagement: Transparent reporting of LCA findings enables manufacturers to communicate their sustainability efforts effectively to consumers. Eco-labels and lifecycle data summaries foster trust and encourage informed purchasing decisions.

- Supply Chain Optimization: LCA insights extend beyond packaging design, helping manufacturers identify inefficiencies in their supply chains. This includes optimizing raw material sourcing, reducing transportation emissions, and enhancing collaboration with recycling partners.

- Circular Economy Integration: LCA facilitates the transition to circular economy models by emphasizing reuse, recycling, and resource recovery. For instance, closed-loop systems for paper-based packaging can significantly reduce waste and conserve energy.

- Corporate Sustainability Reporting: Many manufacturers use LCA results to bolster their Environmental, Social, and Governance (ESG) reporting. By quantifying lifecycle impacts, they demonstrate commitment to sustainability goals and attract eco-conscious investors.

Through these applications, LCA empowers packaging manufacturers to balance functionality, cost-efficiency, and environmental stewardship, positioning them as leaders in sustainable innovation.

Challenges and Limitations of Life Cycle Assessment

Life Cycle Assessment (LCA) offers valuable insights into environmental impacts, but its application in the packaging industry is accompanied by several challenges and limitations:

- Data Availability: Gathering accurate and comprehensive lifecycle data is often hindered by the complexity of modern supply chains. For example, tracking raw material origins, energy usage, and waste outputs requires extensive collaboration between suppliers, manufacturers, and recyclers.

- Methodological Variability: Different LCA methodologies, such as cradle-to-cradle or cradle-to-grave frameworks, can produce inconsistent outcomes. This variability complicates comparisons between materials or designs and may influence decision-making processes.

- Scope Limitations: Narrowly defined study scopes can overlook critical environmental impacts, such as biodiversity loss, water pollution, or social factors. Expanding the scope to include these aspects often increases analysis complexity.

- Cost and Time Constraints: Conducting an LCA can be resource-intensive, requiring specialized software, expertise, and significant time for data collection and interpretation. Smaller manufacturers may face challenges in allocating the necessary resources.

- Dynamic Lifecycle Factors: Packaging lifecycles are influenced by evolving market trends, consumer behavior, and regional infrastructure, such as recycling systems. These dynamic variables can affect the accuracy of LCA findings over time.

- Integration of Social Metrics: While environmental impacts are central to LCA, incorporating social metrics, such as labor conditions and community well-being, into the assessment remains a challenge. Addressing these factors may require methodological advancements.

Despite these challenges, innovations in LCA software, improved data-sharing practices, and evolving global standards are helping manufacturers overcome many of these limitations. By addressing these issues, the packaging industry can leverage LCA as a powerful tool for driving sustainability and reducing ecological footprints.

Emerging Trends in Life Cycle Assessment for Packaging

As sustainability continues to dominate global agendas, the packaging industry is witnessing transformative advancements in Life Cycle Assessment (LCA). These innovations are not only reshaping how manufacturers approach environmental impact analysis but are also driving the adoption of more efficient and eco-friendly practices. Key trends include:

- Advanced LCA Software Integration: The rise of sophisticated digital tools is revolutionizing LCA by automating data collection, streamlining impact modeling, and delivering actionable insights with greater precision. Platforms now leverage machine learning algorithms to predict lifecycle outcomes, enabling faster and more reliable decision-making.

- Circular Economy Implementation: Emphasis on circular design principles aims to minimize waste and maximize resource efficiency. Packaging is increasingly being designed for reuse, recyclability, and biodegradability, aligning with cradle-to-cradle frameworks that prioritize closed-loop systems.

- Dynamic Data Sharing and Collaboration: Collaboration between manufacturers, recyclers, and policymakers is becoming more structured, with shared databases facilitating real-time access to lifecycle data. This transparency accelerates the identification of improvement opportunities across supply chains.

- Regional Customization of LCAs: With growing awareness of localized environmental challenges, companies are tailoring LCA studies to reflect regional variations in energy grids, recycling infrastructure, and consumer behavior. This localized approach ensures more accurate and relevant assessments.

- Integration of Social Metrics: Emerging LCA methodologies are beginning to incorporate social impact factors, such as labor conditions and community well-being, alongside environmental metrics. This holistic perspective broadens the scope of sustainability assessments.

- Real-Time Monitoring and Lifecycle Optimization: IoT-enabled sensors and blockchain technology now allow for real-time monitoring of packaging lifecycles. These innovations enhance traceability and optimize processes, from material sourcing to end-of-life management.

These trends underscore the evolving role of Life Cycle Assessment in packaging, bridging the gap between environmental responsibility and operational efficiency. By embracing these advancements, manufacturers can not only meet regulatory requirements but also cater to a growing consumer base that values sustainability.