Straight tuck end boxes are versatile paper-based packaging solutions featuring tuck-in flaps on both ends, widely utilized across retail, food, and cosmetic industries for storing, branding, and shipping products securely. Constructed from durable, eco-friendly materials like cardboard, kraft paper, and corrugated fiberboard, these boxes ensure sustainability and structural integrity. They are customizable in various designs, shapes, and finishes, allowing businesses to align their packaging with branding goals. Artwork for these boxes involves advanced die-line templates and decorative techniques such as spot UV, embossing, and foil stamping, creating visually striking and brand-reinforcing designs. Diverse printing methods, including digital, flexographic, and lithographic printing, deliver vibrant and durable results, further enhanced by protective laminations. With features like foam inserts, dividers for added protection, and lightweight yet sturdy construction for efficient shipping, these boxes offer a perfect blend of functionality, cost-effectiveness, and environmental responsibility. Businesses can order in bulk for affordability without compromising quality, making straight tuck end boxes a premium yet budget-friendly solution for all packaging needs.

What are straight tuck end boxes?

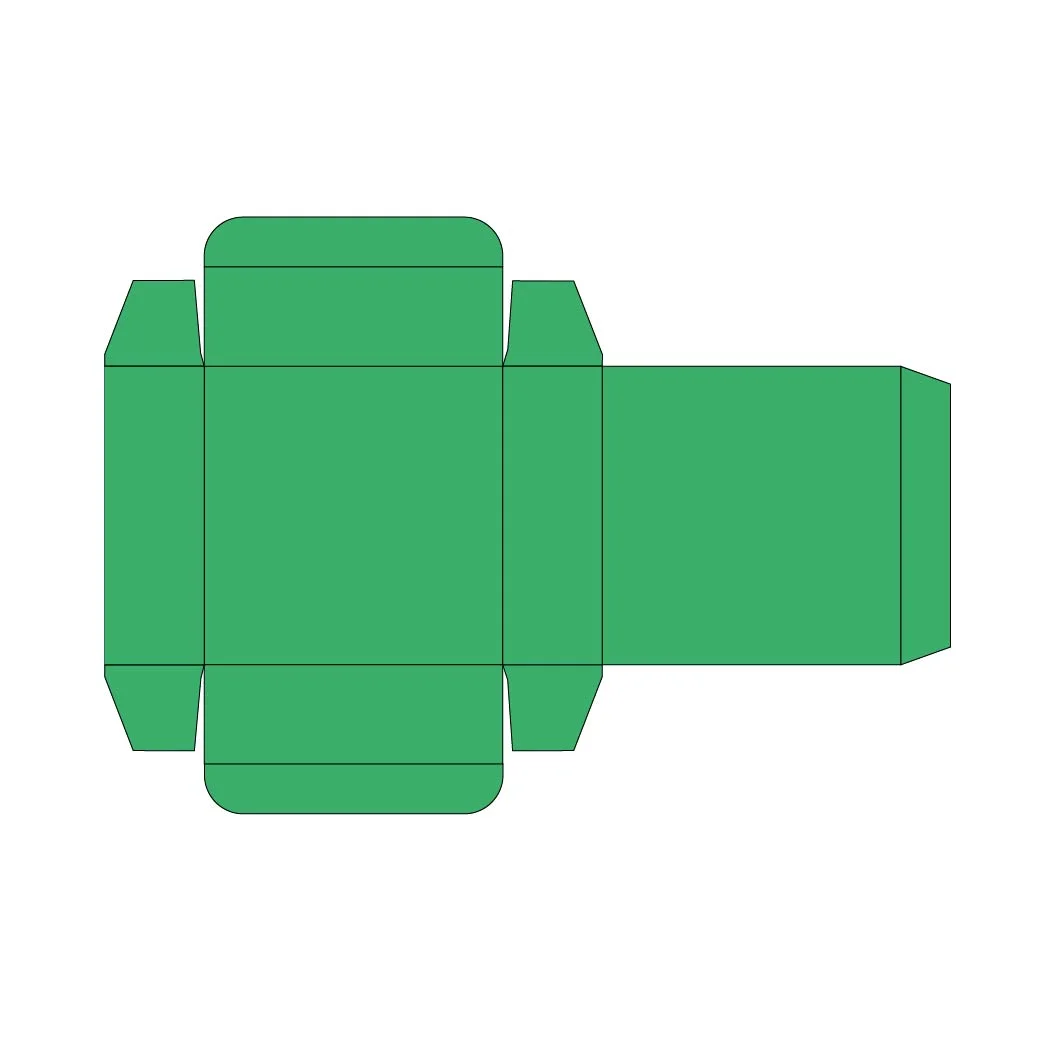

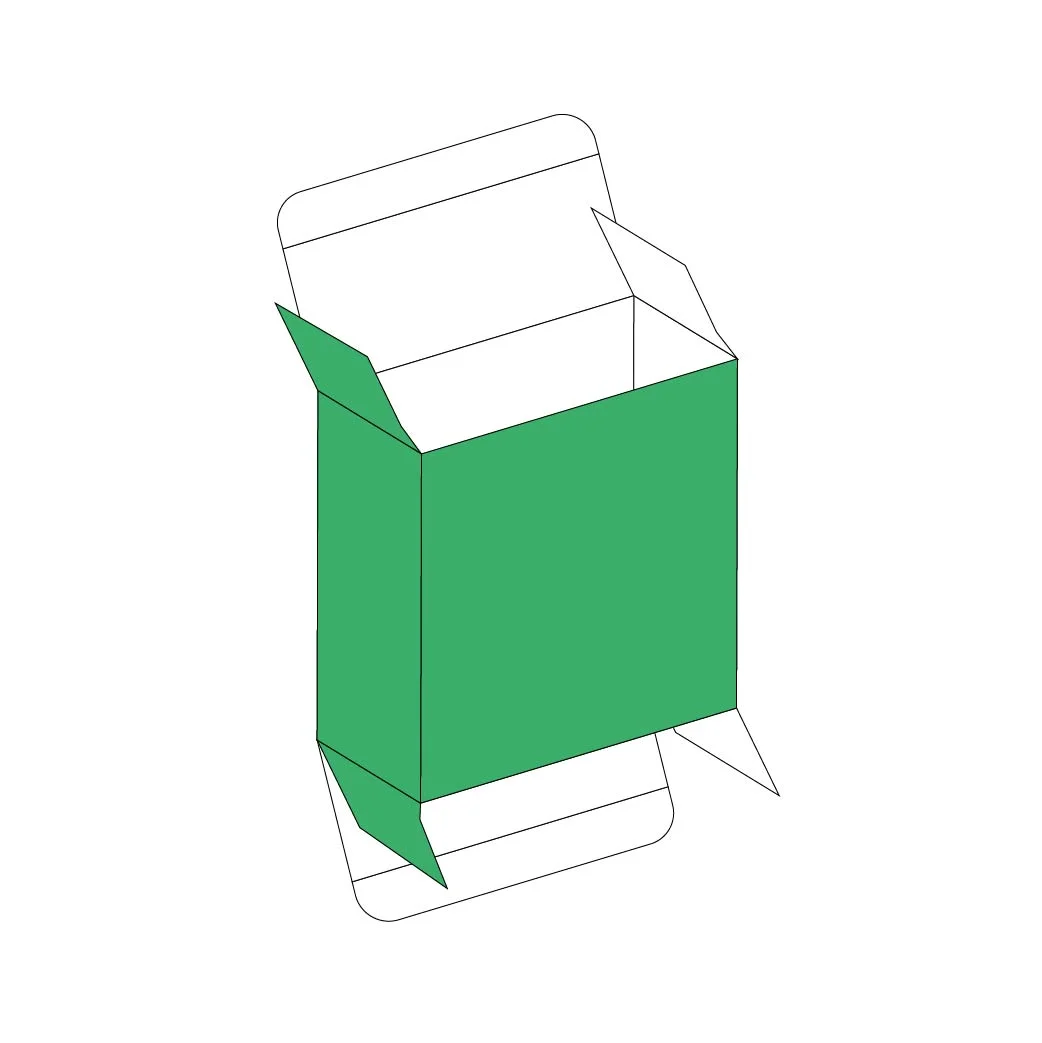

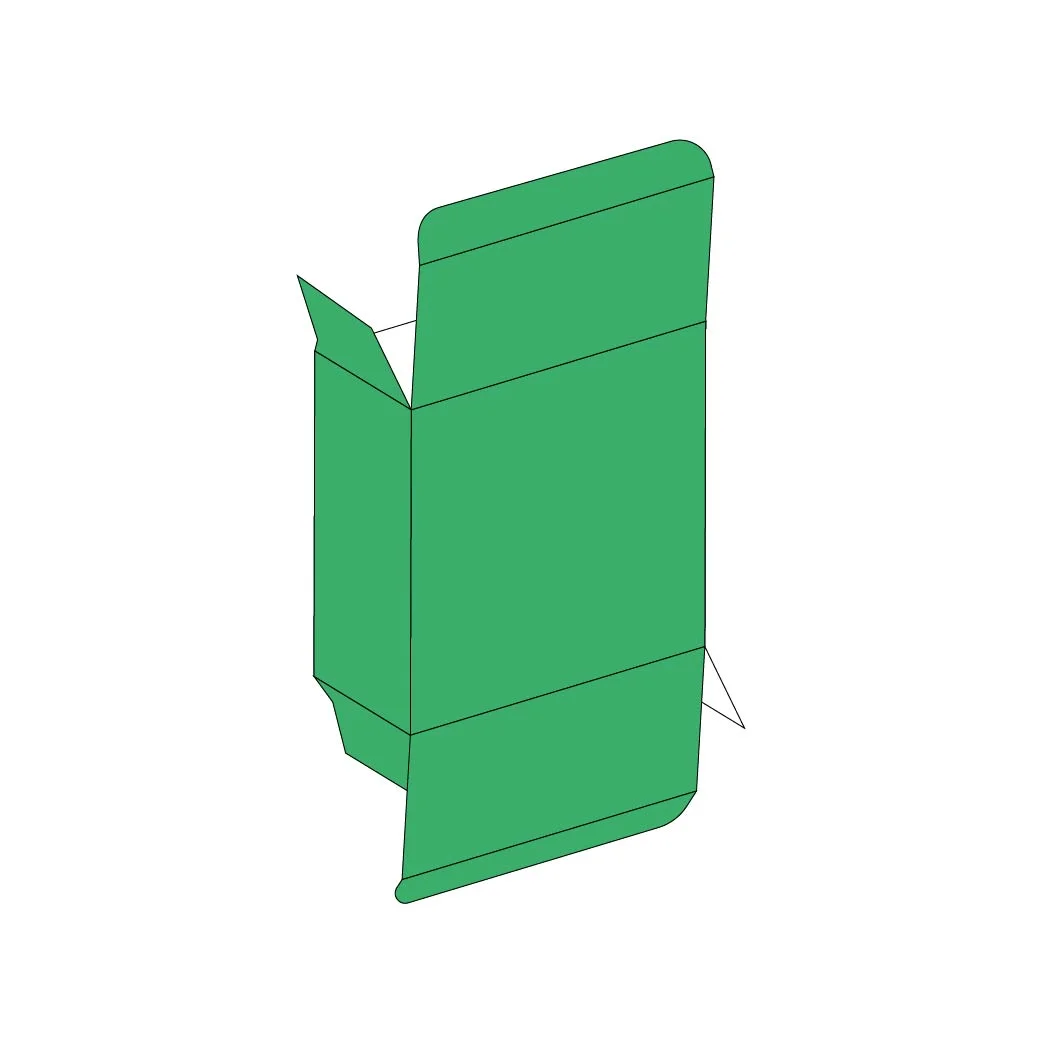

Straight tuck end boxes are paper-based packaging containers featuring tuck-in flaps on both ends of the box, used for storing, branding, and shipping products safely. Straight tuck end boxes are mostly used in retail, food, and cosmetic industries for the packaging and presentation of products. Custom straight tuck end boxes are made from durable and eco-friendly materials like card stock, kraft, paperboard, and corrugated fiberboard. These straight tuck end boxes are designed using different printing approaches like spot UV, stamp foiling, embossing, and debossing. You can customize straight tuck end boxes in different designs, shapes, and materials to match your brand.

What materials are straight tuck end boxes made of?

Straight tuck end boxes are crafted from eco-friendly and durable materials such as cardboard, kraft paper, corrugated fiberboard, and rigid paperboard to meet sustainability goals while ensuring structural integrity. Cardboard is a popular choice due to its lightweight nature, affordability, and ability to protect products during transit. Additionally, these boxes can be enhanced with premium cover papers like solid color, custom printed, foil, laminated, embossed, matte, or gloss finishes to elevate the visual appeal of product packaging.

How are artwork designs created for straight tuck end boxes?

Custom artwork design is a critical step in the production of straight tuck end boxes. By incorporating unique imagery, typography, and brand logos, businesses can create packaging that captures consumer attention and reinforces brand identity. Designers often use advanced software to develop precise die-line templates, ensuring the artwork aligns perfectly with the box dimensions. Additionally, decorative add-ons such as spot UV, embossing, debossing, and foil stamping can be incorporated for a premium finish that highlights key design elements.

What printing and finishing methods can be used for straight tuck end boxes?

Straight tuck end boxes can be manufactured using a variety of advanced printing techniques to achieve vivid and durable designs. Popular printing methods include:

- Digital printing

- Flexographic printing

- Lithography

- Screen printing

- UV varnishing

- Foil printing

- Inkjet printing

- Rotogravure

- Embossing

- Debossing

- Offset lithography

- Stamp foiling

- Laser printing

- Letterpress printing

- 3D printing

These techniques allow businesses to create vibrant, high-quality packaging that enhances brand presence. Custom finishing options, such as matte or gloss lamination, further protect the printed designs while adding a sophisticated touch.

Enhance durability with our sturdy straight tuck end boxes

Durability is a key feature of straight tuck end boxes, as they are constructed from strong materials like cardboard and corrugated fiberboard. These materials offer high folding strength and long-lasting performance, making them ideal for protecting retail, food, and cosmetic products. Their robust construction ensures that contents remain safe during transportation and storage.

Store your products with added protection

Straight tuck end boxes can be customized with protective features such as foam inserts, dividers, and compartments, ensuring that products are securely packaged and well-organized. These enhancements minimize movement during transit and prevent damage, making them ideal for fragile items. By combining functionality with visual appeal, these boxes provide optimal storage solutions while enhancing brand visibility.

Encourage sustainability with our recyclable straight-tuck end boxes

Sustainability is a cornerstone of straight tuck end box production. These boxes are made from recyclable materials like kraft paper and card stock, reducing environmental impact while meeting consumer demand for eco-friendly packaging. Choosing recyclable materials demonstrates a commitment to responsible business practices and helps brands align with green initiatives.

Efficiently ship your products with our straight tuck end boxes

Straight tuck end boxes are lightweight and compact, making them ideal for shipping and transportation. Their sturdy design ensures that products remain protected throughout the delivery process. These boxes can be shipped across the United States, and customers can track their orders in real-time for added convenience.

Save money with our affordable straight tuck end boxes

Businesses can save costs by ordering straight tuck end boxes in bulk without compromising on quality. Our wholesale options allow for orders ranging from a minimum of 100 to a maximum of 100,000 boxes, all offered at competitive prices. This cost-effective solution is perfect for businesses looking to invest in premium packaging while staying within budget.

Why choose PackHit for packaging and shipping products?

PackHit offers a complete range of design, material, and customization options to meet all your packaging needs. Our services include:

- Designing custom straight tuck end boxes that align with your brand identity.

- Providing durable materials and innovative designs for enhanced functionality.

- Using advanced printing techniques to create visually striking packaging.

- Offering 2D and 3D proofs to ensure accuracy before production.

- Flexible order quantities to suit businesses of all sizes, from startups to large enterprises.

To get started, fill out our convenient quotation form and customize your straight tuck end boxes to reflect your brand’s unique identity.