A packaging sample is a physical prototype used to test design, material quality, and functionality before mass production. It helps validate branding, ensure product protection, and improve customer experience. There are three main types: printed, unprinted, and preproduction samples, each serving a specific purpose in development. Packaging samples are crucial for industries like food, cosmetics, pharmaceuticals, electronics, and e-commerce. They help maintain quality, brand consistency, and regulatory compliance while reducing costly errors. Requesting a sample involves defining requirements, choosing a supplier, evaluating the sample, and providing feedback for refinement.

What is a Packaging Sample?

A packaging sample is a tangible representation of a packaging design, typically used to test and validate various aspects such as material quality, structural integrity, and visual appeal. It allows manufacturers to identify potential issues, make necessary adjustments, and ensure compliance with industry standards before mass production. Packaging samples are particularly valuable for custom packaging solutions, where unique designs and specifications are required.

What are the Characteristics of Packaging Samples?

Packaging samples serve as critical prototypes designed to evaluate, refine, and validate various aspects of a product’s packaging before mass production.

Below are the key characteristics that define their effectiveness:

- Material Testing: Examines the quality, durability, and sustainability of materials to ensure they meet industry standards while maintaining cost-efficiency.

- Design Validation: Confirms that the packaging design aligns with branding guidelines, marketing objectives, and accurately reflects the product’s identity and appeal.

- Structural Integrity: Tests the ability of the packaging to withstand physical stress during handling, storage, and transportation, reducing the risk of product damage.

- Regulatory Compliance: Verifies adherence to legal, environmental, and industry-specific standards, minimizing risks of penalties or recalls.

- Customer Experience: Assesses the unboxing process, ease of use, and aesthetic appeal to enhance customer satisfaction and strengthen brand loyalty.

- Prototyping Accuracy: Ensures close alignment with the final product in terms of dimensions, materials, and functionality, offering a realistic preview for stakeholders.

- Durability: Demonstrates the packaging’s ability to protect the product under real-world conditions such as transportation and storage.

- Visual Appeal: Captures the brand’s identity with attractive designs that align with marketing goals and capture customer attention.

- Functionality: Evaluates practical aspects such as secure closures, ease of use, and compatibility with the product’s dimensions and shape.

- Material Flexibility: Facilitates testing of multiple material types to identify options that balance cost, sustainability, and performance.

By addressing these characteristics, manufacturers can identify potential issues early, refine their designs, and confidently transition to production. This ensures the packaging not only meets quality and regulatory standards but also aligns with branding and consumer expectations.

What are the Types of Packaging Samples?

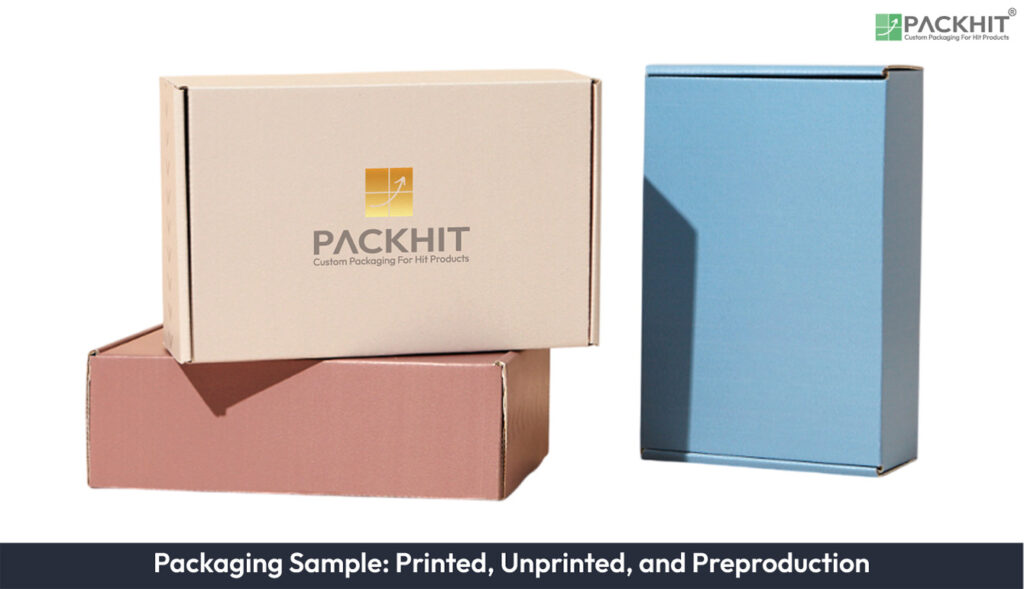

Packaging samples can be broadly classified into three main types: printed, unprinted, and preproduction samples. Each type serves a specific role in the packaging development process.

The three types of packaging samples are listed below:

1. Printed Packaging Samples

Printed packaging samples are prototypes that include the final design elements, such as logos, colors, and text. These samples are used to evaluate the visual aspects of the packaging and ensure that the branding is accurately represented. They are particularly useful for marketing teams and stakeholders to approve the design before production.

2. Unprinted Packaging Samples

Unprinted packaging samples focus on the structural and material aspects of the packaging. These prototypes are typically made from the same materials as the final product but do not include any printed designs. They are used to test the packaging’s durability, fit, and functionality.

3. Preproduction Samples

Preproduction samples are the closest representation of the final packaging. They include both the structural and design elements and are produced using the same methods and materials as the final product. These samples are used for final approval and quality assurance before mass production begins.

Why are Packaging Samples Important?

Packaging samples play a critical role in the product development process. They help manufacturers avoid costly mistakes, ensure customer satisfaction, and maintain brand integrity. Below are some key reasons why packaging samples are essential:

- Cost Efficiency: Identifying and resolving issues during the sampling phase prevents expensive errors in mass production and reduces waste by addressing flaws early in the process.

- Quality Assurance: Ensures that the packaging meets industry standards, protects the product effectively, and satisfies customer expectations for reliability and performance.

- Brand Consistency: Validates that the packaging design accurately reflects the brand’s identity, messaging, and visual appeal, ensuring cohesive representation across all products.

- Regulatory Compliance: Confirms that the packaging adheres to legal, environmental, and industry-specific regulations, mitigating risks of penalties or recalls.

Which Industries Use Packaging Samples?

Packaging samples are used by various industries to ensure product safety, enhance customer experience, and support branding efforts. Some of the key industries that rely on packaging samples include:

- Food and Beverage: Ensures that packaging is food-safe, leak-proof, and visually appealing while maintaining product freshness and meeting compliance standards such as FDA regulations.

- Cosmetics and Personal Care: Validates the packaging’s aesthetic qualities, functionality, and compatibility with product formulations, ensuring it meets both luxury and retail requirements.

- Pharmaceuticals: Confirms compliance with stringent safety and regulatory standards, including tamper-evidence, sterility, and clear labeling for medical packaging.

- Electronics: Tests protective features such as shock absorption and moisture resistance to prevent damage during transit and storage.

How to Request a Packaging Sample?

To request a packaging sample, follow the steps mentioned below:

- Define Requirements: Specify the dimensions, materials, design elements, and any unique features required for the sample, ensuring alignment with the product’s needs and branding goals.

- Choose a Supplier: Research and select a packaging supplier or manufacturer that specializes in your industry and offers comprehensive sample services, including printed and preproduction options.

- Submit a Request: Provide a detailed specification sheet and any necessary artwork or branding guidelines to the supplier to ensure clarity and precision.

- Review the Sample: Conduct a thorough evaluation of the sample, focusing on material quality, structural integrity, design accuracy, and compliance with industry standards.

- Provide Feedback: Share constructive feedback with the supplier, outlining required adjustments or improvements before finalizing the sample for production.

How is Custom Artwork Design Incorporated into Packaging Samples?

Custom artwork design is typically integrated during the prototyping phase of printed packaging samples. Manufacturers submit high-resolution design files, including logos, branding colors, and specific text, as part of the specification process. Suppliers use these files to create a sample that accurately represents the final design. This process ensures that visual branding is consistent and aligns with marketing objectives before mass production begins. Any necessary adjustments to the artwork can then be made based on feedback from stakeholders.