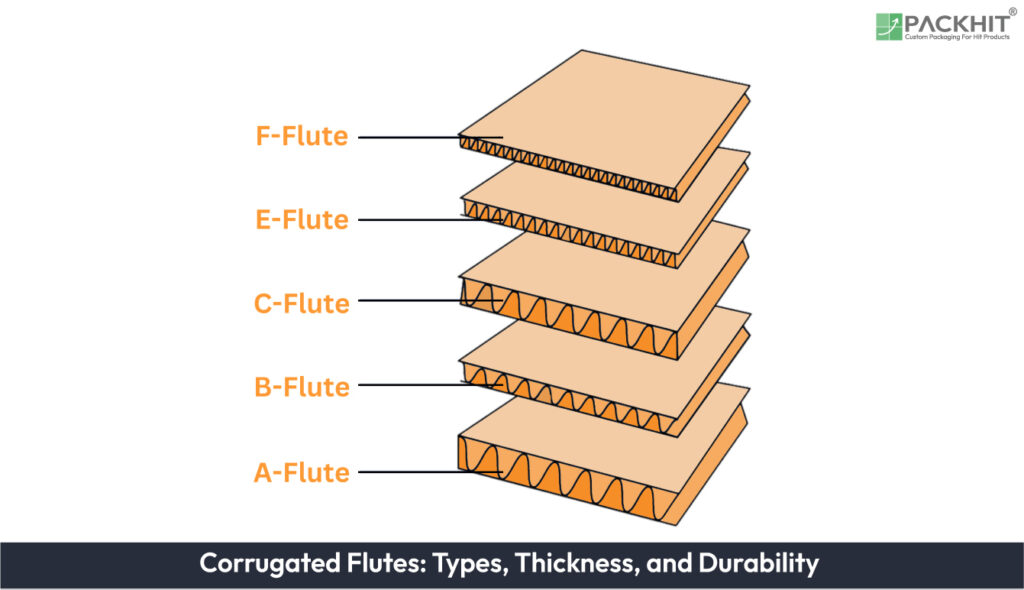

Corrugated flutes are the structural core of corrugated fiberboard, designed as wave-like arches sandwiched between liners to enhance strength, cushioning, and rigidity. These flutes are formed using a corrugating machine and glued between flat sheets, offering essential properties like thickness for durability, strength for compression resistance, cushioning for shock absorption, and flexibility for foldability and print quality. Flute types vary as A-flute provides maximum cushioning, B-flute balances crush resistance and printability, C-flute offers general-purpose strength, E-flute delivers superior print surfaces, and F-flute excels in luxury packaging with fine detail.

Flute thickness directly affects durability; thicker flutes like A and C improve strength and cushioning, while thinner flutes like E and F enhance visual appeal and are ideal for high-quality printing. Durability also depends on material quality, environmental exposure, adhesive bonding, flute profile, and production accuracy. Applications span industrial, retail, and food sectors, with flute type chosen based on product weight, print requirements, shipping conditions, and budget. Ultimately, choosing the right flute ensures optimal packaging performance across diverse use cases.

What are Corrugated Flutes?

Corrugated flutes are the arched, wave-like structures that form the core of corrugated fiberboard. They are created by passing a sheet of paper through a corrugating machine, which shapes the paper into a series of ridges and grooves. These flutes are then glued between two flat liners to form a corrugated board. The primary purpose of flutes is to provide strength, cushioning, and rigidity to the board, enabling it to withstand compression, stacking, and impact forces.

What are the Core Properties of Corrugated Flutes?

Corrugated flutes possess distinct properties that contribute to the functionality and versatility of corrugated fiberboard. These properties define the board’s structural and protective capabilities, making it suitable for various packaging applications. Below is a detailed list of the core properties:

- Thickness: The height of the flute determines the overall thickness of the corrugated board, which directly influences its rigidity and durability. Flute profiles range from thicker options, such as A-flutes, to thinner ones like F-flutes.

- Strength: Flutes enhance the board’s ability to resist compression and stacking forces. This structural stability ensures that products remain protected during handling and storage.

- Cushioning: The arched structure of flutes absorbs shocks and vibrations effectively, safeguarding items from impact damage during transportation.

- Flexibility: Smaller flute profiles, such as E and F flutes, improve foldability and provide smoother surfaces, making them ideal for high-quality printing and intricate packaging designs.

These core properties make corrugated flutes indispensable in the packaging industry, allowing manufacturers to tailor board specifications to meet diverse product protection and presentation needs.

What are the Different Types of Corrugated Flutes?

Corrugated flutes are categorized based on their size and profile. Each type serves specific functional roles, making them suitable for different packaging applications. The most common flute types include A, B, C, E, and F flutes.

A-Flute

A-flute, the largest flute profile with approximately 33 flutes per foot and a thickness of 4.7 mm, offers superior cushioning and stacking strength. These attributes make it ideal for heavy-duty shipping boxes, fragile items, and applications requiring enhanced protection against compression and impact forces.

B-Flute

B-flute, characterized by about 47 flutes per foot and a thickness of 3.2 mm, boasts better crush resistance and smoother printability compared to A-flute. It is widely used for retail packaging, die-cut boxes, and applications demanding a refined printing surface and moderate structural strength.

C-Flute

C-flute, the most commonly used profile with roughly 39 flutes per foot and a thickness of 4.0 mm, strikes a balance between cushioning and stacking strength. It is versatile and suitable for general-purpose shipping boxes, food packaging, and products requiring a combination of durability and functionality.

E-Flute

E-flute, with approximately 90 flutes per foot and a thickness of 1.6 mm, provides an excellent surface for high-quality printing and enhanced foldability. It is commonly employed in high-end retail packaging, custom-printed boxes, and lightweight product applications where aesthetics and precision are paramount.

F-Flute

F-flute, the smallest profile with about 125 flutes per foot and a thickness of 0.8 mm, offers exceptional print quality and adaptability for intricate designs. It is ideal for luxury packaging, small product boxes, and point-of-purchase displays where visual appeal and foldability are key considerations.

What Factors Affect the Durability of Corrugated Flutes?

The durability of corrugated flutes is influenced by several critical factors that determine the structural integrity and performance of the corrugated board. Addressing these factors ensures optimal protection and longevity in various packaging applications.

- Material Quality: The type and strength of paper used for the flutes and liners are pivotal. High-quality kraft paper provides superior robustness, while recycled paper may reduce durability under stress.

- Environmental Conditions: Exposure to fluctuating temperature, humidity, and moisture can weaken the board over time. For example, high humidity can compromise the adhesive bonds and cause delamination.

- Adhesive Strength: The bonding quality between the flutes and liners ensures the board remains intact under compression and handling. Weak adhesive can lead to separation and reduced structural reliability.

- Flute Profile: The size and type of flute directly correlate with durability. Thicker profiles, such as A-flute or C-flute, offer better resistance to wear and stacking pressures compared to thinner profiles.

- Manufacturing Precision: Proper alignment and consistent glue application during production prevent defects and enhance durability over the board’s lifecycle.

By understanding and optimizing these factors, manufacturers can ensure corrugated boards meet the demanding requirements of their packaging applications, offering both protection and longevity.

How Does Corrugated Flute Thickness Impact Its Durability and Performance?

The thickness of corrugated flutes directly impacts the durability and performance of the corrugated board. Thicker flutes, such as A and C flutes, provide better cushioning and stacking strength, making them suitable for heavy-duty applications. Thinner flutes, such as E and F flutes, offer enhanced printability and are ideal for lightweight or retail packaging.

What are the Applications of Corrugated Flutes?

Corrugated flutes are used across various industries for packaging and shipping. Their versatility and customizable properties make them suitable for a wide range of applications.

Industrial Packaging

Corrugated flutes are commonly used in industrial packaging to protect heavy machinery, automotive parts, and other bulky items. A-flute and C-flute boards are preferred for their superior cushioning and stacking strength.

Retail Packaging

Retail packaging often requires high-quality printing and aesthetic appeal. E-flute and F-flute boards are ideal for creating custom-printed boxes, point-of-purchase displays, and luxury packaging.

Food Packaging

Corrugated flutes are widely used in food packaging due to their ability to provide insulation and protection. C-flute and B-flute boards are commonly used for pizza boxes, beverage carriers, and produce trays.

How to Choose the Right Corrugated Flute?

Selecting the right corrugated flute depends on the specific requirements of your packaging application. Consider the following factors:

- Product Weight: Heavier products require thicker flutes for better support and cushioning.

- Print Quality: Smaller flutes, such as E and F flutes, offer smoother surfaces for high-quality printing.

- Shipping Conditions: Evaluate the environmental conditions and handling requirements during transportation.

- Cost: Balance the cost of materials with the desired performance and durability.

Corrugated flutes play a vital role in the performance and functionality of corrugated fiberboard. By understanding the types, thickness, and durability of flutes, manufacturers can make informed decisions to optimize their packaging solutions.