To accurately measure tissue box dimensions, start by identifying the box shape, as this determines the measurement method. Use a precise measuring tool like a ruler or caliper, ensuring it’s placed flush against the surface. Measure the length, width, and height based on the box shape, and account for material thickness to obtain internal dimensions. Accurate measurements are vital for shelf compatibility, efficient packaging, and user experience. Standard tissue boxes come in rectangular, square, and flat forms with defined size ranges, while custom boxes may vary based on branding or functionality. Factors like tissue count, material thickness, and dispensing mechanism influence box size, and custom dimensions require special design considerations, including volume optimization and unique shapes.

- How to Measure Tissue Box Dimensions?

- Step 1: Identify the Box Shape

- Step 2: Use a Measuring Tool

- Step 3: Measure length

- Step 4: Measure the width

- Step 5: Measure the height

- Why are Accurate Tissue Box Dimensions Important?

- What are the Standard Tissue Box Dimensions?

- Rectangular Tissue Boxes

- Square Tissue Boxes

- Flat Tissue Boxes

- Can Tissue Box Dimensions be Customized?

- What are the Factors that Influence Tissue Box Dimensions?

- Custom Tissue Box Dimensions

How to Measure Tissue Box Dimensions?

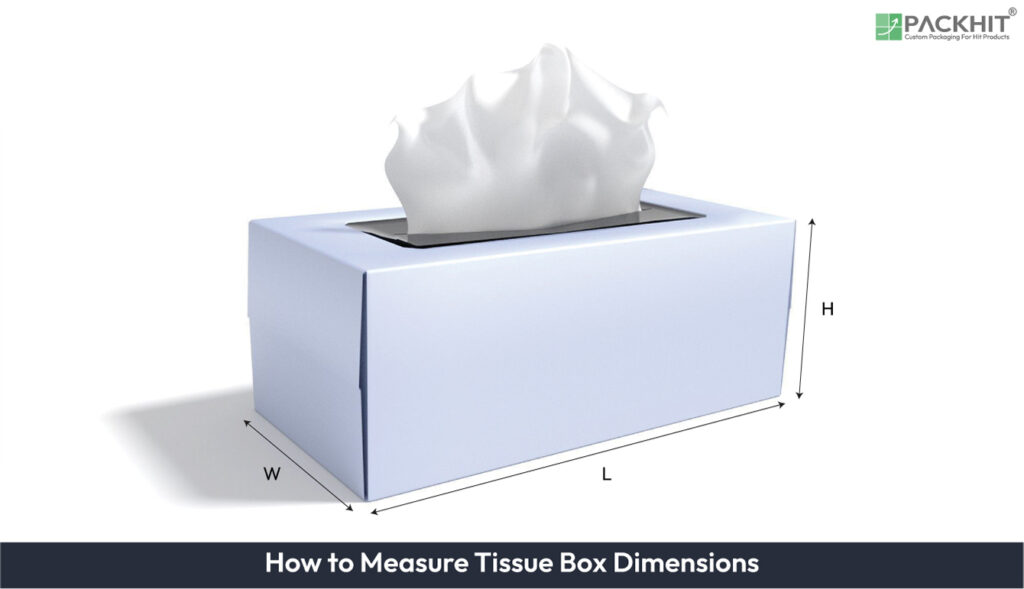

Accurate measurement of tissue box dimensions involves the use of calibrated tools and adherence to standardized procedures.

Here is the step-by-step process to measure a tissue box’s dimensions:

Step 1: Identify the Box Shape

Determine whether the box is rectangular, square, or flat. This classification will guide the measurement approach and tools required.

Step 2: Use a Measuring Tool

Employ a ruler, caliper, or measuring tape with a precision of at least 0.1 inches (0.25 cm). Ensure the tool is placed flush against the box surface to avoid measurement errors.

Step 3: Measure length

Measure the longest external side and record that number as the box length in inches or centimeters. Use a ruler, measuring tape, or digital caliper, such as a 12-inch steel ruler, 300 mm tape, or 150 mm digital caliper. Place the tool flush against the box and align it with the longest straight edge. Read the mark at eye level to avoid parallax error. Use a precision of 0.1 inches (0.25 cm) for packaging purposes.

Step 4: Measure the width

Place the ruler or caliper across the top center and read the distance between outer edges for external width. Cardboard thickness commonly adds 0.05–0.1 inches per side; subtract twice that amount from the external width to get the internal width.

Step 5: Measure the height

Measure the vertical distance from the box base to the top surface, including any closed lid or dispensing flap. If the box uses a pop-up or pull-through dispenser, allow about 5% extra internal height to prevent jams. Record all dimensions in the same unit and round to the nearest 0.1 inch for design and ordering.

Why are Accurate Tissue Box Dimensions Important?

Precise tissue box dimensions are crucial for various applications, including:

- Ensuring compatibility with retail shelving and storage systems.

- Optimizing packaging for transportation to reduce shipping costs.

- Enhancing consumer experience through ergonomic and visually appealing designs.

What are the Standard Tissue Box Dimensions?

Tissue boxes are typically categorized into three standard shapes: rectangular, square, and flat. Each shape has distinct dimensional ranges that cater to specific use cases and storage requirements:

Rectangular Tissue Boxes

Rectangular boxes are the most common format, often used for household and office settings. Standard dimensions for these boxes are approximately 9 inches (22.86 cm) in length, 4.5 inches (11.43 cm) in width, and 2 inches (5.08 cm) in height. These dimensions are optimized for compact storage and easy dispensing of tissues.

Square Tissue Boxes

Square tissue boxes are designed for aesthetic appeal and are frequently used in luxury or decorative settings. Their dimensions typically range from 4.5 inches (11.43 cm) to 5.5 inches (13.97 cm) on each side, with a height of 4.5 inches (11.43 cm). This uniformity in dimensions ensures a balanced visual profile.

Flat Tissue Boxes

Flat boxes are designed for portability and are commonly used in travel or compact storage scenarios. These boxes measure approximately 8.5 inches (21.59 cm) in length, 4.5 inches (11.43 cm) in width, and 1.5 inches (3.81 cm) in height. Their slim profile makes them ideal for tight spaces.

Can Tissue Box Dimensions be Customized?

Yes, tissue box dimensions can be customized, whichallows brands to create unique designs that align with their visual identity and functional needs. This can include unusual shapes like hexagonal, cylindrical, or oversized boxes tailored to specific applications.

What are the Factors that Influence Tissue Box Dimensions?

Several factors determine the dimensions of tissue boxes, including functional requirements, material constraints, and consumer preferences. Understanding these factors is essential for manufacturers aiming to optimize their designs.

Tissue Count and Ply

The number of tissues and their ply (single-ply, two-ply, etc.) directly impact the box’s size. Higher tissue counts or thicker plies require larger boxes to accommodate the increased volume while maintaining structural integrity.

Material Thickness

The thickness of the cardboard or other materials used for the box affects its external dimensions. Thicker materials may add up to 0.1 inches (0.25 cm) to each side, which must be accounted for during the design phase.

Dispensing Mechanism

Boxes with advanced dispensing mechanisms, such as pop-up or pull-through designs, may require additional internal space to ensure smooth operation. This can increase the overall dimensions by up to 5% compared to standard designs.

Custom Tissue Box Dimensions

Custom tissue boxes are designed to meet specific branding, functional, or aesthetic requirements. These boxes often deviate from standard dimensions and require specialized measurement and design considerations.

Design Flexibility

Custom boxes can be tailored to unique shapes, such as hexagonal or cylindrical designs, which necessitate advanced measurement techniques and prototyping to ensure accuracy.

Volume Optimization

Manufacturers often calculate the internal volume of custom boxes to ensure they can hold the desired tissue count without compromising usability. This involves integrating the dimensions into volume formulas specific to the box shape.