Measure the shoe box by recording external and internal Length × Width × Height in defined units and tolerances. Measure length along the longest external edge, width perpendicular to length, and height from base to the top edge; for separate lids, record base and lid heights individually. Take three readings near corners and at the center, use the smallest internal reading for fit, and record to 1/8 in (3 mm) or two decimal places for carrier systems. Include material thickness and padding (examples: tissue 0.02 in, foam 0.25 in), note tolerances (example: ±0.125 in), and store measurements as L × W × H with metric equivalents. Use calibrated tools (tape measure, caliper, steel ruler), inspect 5% of production lots, and record the mean and standard deviation. Reference common standards and averages (examples: men’s 14 × 10 × 5 in; women’s 13 × 7.5 × 4 in; kids 9 × 6 × 3 in; averages small 10 × 6 × 4 in, medium 12 × 8 × 5 in, large 14 × 10 × 6 in). Choose custom dimensions to convey brand identity, ensure a snug fit for unusual shapes, and refine unboxing presentation. For shipping, compute dimensional weight using L × W × H and the carrier divisor and note common pack sizes such as USPS Priority Mail 14.375 × 7.5 × 5.125 in.

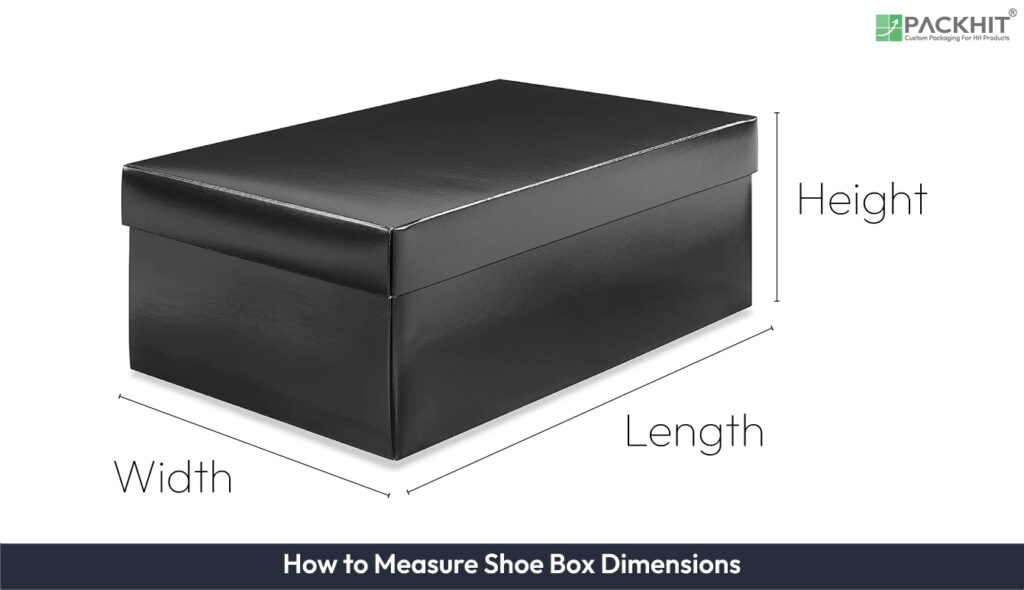

Below is a step-by-step guide to accurately measure shoe box dimensions:

- Step 1: Measure the Length of the Shoe Box

- Step 2: Measure the Width of the Shoe Box

- Step 3: Measure the Height of the Shoe Box

- Step 4: Record the Dimensions

- Why Measuring Shoe Box Dimensions is Important?

- What are the Standard Dimensions of Shoe Boxes?

- What are the Average Dimensions of Shoe Boxes?

- Why Should You Consider Custom Shoe Box Dimensions?

- Shoe Box Dimensions for Shipping

Step 1: Measure the Length of the Shoe Box

Measure the longest external side from outer edge to outer edge; this value is the box length. Place the assembled box on a flat surface. Use a tape measure, steel ruler, or digital caliper (measuring tools, such as tape measure, caliper, and ruler) and run the tool along the top edge while keeping it straight. Record both the external length for shipping purposes and the internal usable length for fit. The internal usable length equals external length minus combined material thickness (two side walls). Take three measurements, near each corner and at the center, and use the smallest internal measurement for product fit, or the average external measurement for size specification. Record to the nearest 1/8 inch (3 mm) for manufacturing drawings; record decimals (two places) for carrier systems if required.

Step 2: Measure the Width of the Shoe Box

Measure the shorter side perpendicular to the length; this is the box width. Align the measuring tool at the box midpoint and measure from outer edge to outer edge. For internal fit, measure the widest internal point inside the box base; that dimension controls how the shoes sit side-by-side. For asymmetrical or curved inserts, measure the usable internal width at three points (toe, mid, heel) and use the smallest value when specifying inserts or dividers. Note any internal partitions or trays and record their effective clearances separately (example: divider reduces usable width by 0.5 in).

Step 3: Measure the Height of the Shoe Box

Measure the vertical distance from the base to the top edge; this is the box height, and for boxes with lids, include the lid. If the box uses a separate lid, measure base height and lid height individually and then record the combined height and each component (example: base 3.5 in, lid 1.5 in, total 5.0 in). For telescoping or tuck-lid designs, measure height with the lid fully closed and with the lid removed; note the lid overlap amount since it affects stacking clearance. For internal clearance, measure from the insole/top of the shoe to the lid interior and add desired packing clearance (typical clearance: 0.25–0.5 in, depending on padding). Record height tolerances as ±0.125 in for production batches.

Step 4: Record the Dimensions

Record dimensions in the order Length × Width × Height and specify units and tolerances. Use inches for US manufacturing and add metric equivalents in parentheses (example: 12.00 × 8.00 × 5.00 in — 30.48 × 20.32 × 12.70 cm). Add manufacturing tolerance (example: ±0.125 in) and note whether dimensions are external or internal. For shipping, compute dimensional weight using L × W × H and the carrier’s divisor; apply the carrier’s published divisor (for example, 139 or 166) if dimensional billing applies. Store measurements on a technical spec sheet with drawing references, material thickness, lid type, and sample photos to ensure consistency across production runs.

- Accuracy tips: Calibrate measuring tools monthly, measure three times and record the smallest internal value for fit.

- Fit checks: Place a sample shoe inside and verify orientation, then measure residual void space (example: 0.3 in at the toe).

- Production sampling: Inspect 5% of a production lot and record the mean and standard deviation for each dimension.

- Packaging notes: Include internal padding thickness (example: tissue 0.02 in, foam 0.25 in) when specifying usable dimensions.

- Presentation effects: Align graphics and die-cut windows to external dimensions; adjust artwork if measured trim varies more than tolerance.

Why Measuring Shoe Box Dimensions is Important?

Accurate measurement of shoe box dimensions is critical for several reasons, including optimizing logistics, reducing shipping costs, and ensuring customer satisfaction. Below are the key impacts of precise shoe box dimensions:

Impact on Shipping Costs

Shoe box dimensions directly affect shipping costs, as carriers often calculate freight charges based on dimensional weight. Selecting the optimal dimensions for shoe boxes can reduce expenses and improve logistics efficiency. For example, a box that is too large may incur higher shipping fees, while a box that is too small may damage the product during transit.

Impact on Storage Optimization

Properly sized shoe boxes maximize storage space and improve organizational practices. Optimized dimensions allow for better stacking and space utilization in warehouses, retail stores, and even customer homes. Compared to irregularly sized boxes, standardized dimensions ensure more efficient use of available storage space.

Criticality in Product Protection

Shoe box dimensions are critical for ensuring the proper fit of shoes within the box. A well-fitted box protects the shoes from dirt, dust, and physical damage during storage and shipping. This is particularly important for high-value or delicate footwear, such as leather shoes or designer heels.

What are the Standard Dimensions of Shoe Boxes?

Standard shoe box dimensions are predefined sizes commonly used in the footwear industry to ensure consistency, cost-effectiveness, and compatibility with shipping carriers. These dimensions vary based on the type of footwear (e.g., men’s, women’s, or kids’ shoes) and are designed to provide a snug and protective fit for the shoes while optimizing storage and shipping efficiency.

Common Standard Sizes

Shoe box dimensions vary depending on the type of footwear they are designed to hold. Below are the most common standard sizes used in the industry:

- Men’s Shoe Boxes: Typically measure 14 x 10 x 5 inches (35.56 x 25.4 x 12.7 cm). These boxes are crafted to accommodate larger footwear, such as boots or athletic shoes, while maintaining structural integrity during transit.

- Women’s Shoe Boxes: Commonly measure 13 x 7.5 x 4 inches (33.02 x 19.05 x 10.16 cm). They are designed for a snug fit, ensuring protection and minimizing unused space for footwear like heels or flats.

- Kids’ Shoe Boxes: Smaller sizes, often around 9 x 6 x 3 inches (22.86 x 15.24 x 7.62 cm). These dimensions are tailored for children’s footwear, providing adequate cushioning and ease of stacking in storage environments.

These standardized sizes streamline packaging processes, enhance compatibility with shipping carriers, and ensure efficient storage in warehouses and retail spaces.

What are the Average Dimensions of Shoe Boxes?

The average dimensions of a shoe box depend on the type of footwear it is designed to hold. Below are typical measurements categorized by shoe type:

- Medium-Sized Shoe Box: Measures 12 inches in length, 8 inches in width, and 5 inches in height (30.48 x 20.32 x 12.7 cm). These dimensions are ideal for standard footwear types, such as casual shoes or sneakers, ensuring a secure fit while maintaining efficient use of packaging space.

- Large Shoe Box: Measures 14 inches in length, 10 inches in width, and 6 inches in height (35.56 x 25.4 x 15.24 cm). This size is designed to accommodate bulkier footwear, such as boots or high-top sneakers, offering adequate protection and structural integrity during transit.

- Small Shoe Box: Measures 10 inches in length, 6 inches in width, and 4 inches in height (25.4 x 15.24 x 10.16 cm). These are best suited for compact items, including sandals, flats, or children’s footwear, providing an efficient and secure packaging solution.

These average dimensions provide a baseline for manufacturers and retailers to design packaging that meets standard shipping and storage requirements while ensuring product protection and presentation.

Why Should You Consider Custom Shoe Box Dimensions?

Custom shoe box dimensions are specifically designed to meet unique branding, storage, or product requirements. Unlike standard sizes, these dimensions offer flexibility and personalization for manufacturers and retailers seeking to enhance their product packaging and presentation.

Advantages of Custom Shoe Box Dimensions

Custom shoe box dimensions offer numerous benefits for manufacturers and retailers aiming to enhance their product packaging. Below are the key advantages of opting for custom shoe dimensions:

- Enhanced Branding: Custom dimensions enable creative designs that reflect a brand’s identity, helping to build a sophisticated and memorable image for the product.

- Perfect Product Fit: Tailored dimensions ensure the box snugly accommodates non-standard shoe sizes or unique footwear shapes, offering superior protection and presentation.

- Improved Customer Experience: Custom packaging can elevate the unboxing experience, adding perceived value and creating a lasting impression on customers.

Shoe Box Dimensions for Shipping

Shipping shoe boxes requires careful consideration of their dimensions to ensure cost-effectiveness and product safety. Carriers often use dimensional weight to calculate shipping fees, making it essential to optimize box sizes for transit.

USPS Priority Mail Shoe Box

The USPS Priority Mail Shoe Box is a popular option for shipping footwear. It measures 14.375 x 7.5 x 5.125 inches (36.51 x 19.05 x 13.02 cm) and is designed to accommodate most standard shoe boxes. This size ensures compatibility with USPS shipping guidelines and provides adequate protection for the contents.

Tips for Shipping Shoe Boxes

- Choose a box size that closely matches the dimensions of the shoes to minimize empty space.

- Use padding materials, such as bubble wrap or tissue paper, to protect the shoes during transit.

- Seal the box securely with packing tape to prevent damage or tampering.

Understanding and accurately measuring shoe box dimensions is essential for manufacturers, retailers, and logistics providers. Whether using standard sizes or custom dimensions, proper measurements ensure optimal packaging, storage, and shipping of footwear. By considering factors such as shipping costs, storage optimization, and product protection, businesses can enhance efficiency and customer satisfaction while reducing operational costs.