Embossing in packaging is a specialized printing and finishing technique that creates a raised or recessed design on the surface of packaging materials, such as paper, cardboard, or plastic. This process enhances the tactile and visual appeal of packaging, making it a popular choice for branding, product differentiation, and premium packaging solutions. By integrating embossing into packaging design, manufacturers can elevate the perceived value of their products while also providing a unique sensory experience for consumers.

- What is Embossing in Packaging?

- How Does the Embossing Process Work?

- What are the Uses of Embossing in Packaging?

- 1. Branding and Logo Enhancement

- 2. Luxury and Premium Packaging

- 3. Product Differentiation

- 4. Special Editions and Gift Packaging

- What Challenges Do Manufacturers Face When Using Embossing in Packaging?

- What are the Future Trends in Embossing for Packaging?

What is Embossing in Packaging?

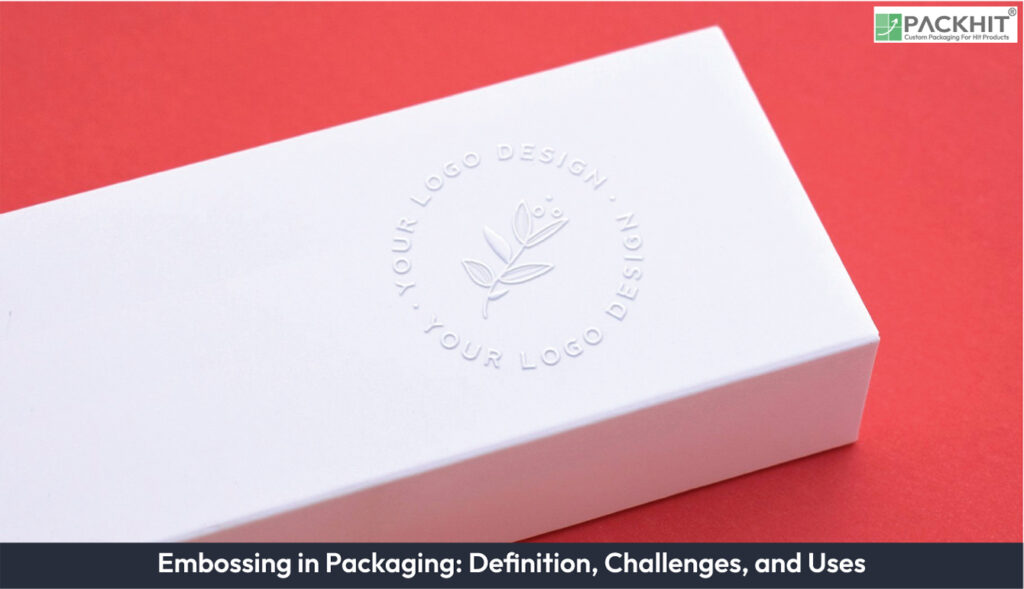

Embossing is a decorative process that involves pressing a design, pattern, or text into a material to create a three-dimensional effect. In the context of packaging, embossing is used to highlight specific elements such as logos, brand names, or intricate patterns. The process is achieved using a combination of heat, pressure, and custom dies, which imprint the desired design onto the packaging material.

What are the Key Properties of Embossing?

Embossing in packaging provides a blend of functional and aesthetic characteristics that make it a preferred choice for enhancing product presentation. The following properties define the unique attributes of embossing in packaging:

- Material Adaptability: Embossing is compatible with a wide range of materials, including paperboard, corrugated cardboard, plastics, and metalized films, offering flexibility for diverse packaging designs.

- Design Complexity: It supports intricate patterns, textures, and detailed visuals, enabling manufacturers to create distinctive and memorable packaging solutions.

- Enhanced Durability: Embossed elements maintain their integrity and premium appearance throughout the lifecycle of the packaging, ensuring long-lasting aesthetic appeal.

- Customizable Features: The embossing process enables the creation of unique, tailored designs, such as logos or brand-specific patterns, thereby enhancing product branding and exclusivity.

How Does the Embossing Process Work?

The embossing process involves several key steps, each of which contributes to the final quality and appearance of the design. Below is a detailed breakdown of the process:

1. Design Preparation

The first step is to create a digital design of the desired embossing pattern. This design is then used to manufacture custom dies, which are typically made from brass, magnesium, or copper. The dies consist of two parts: the male die (raised) and the female die (recessed).

2. Material Selection

The choice of material plays a crucial role in the embossing process. Materials with sufficient thickness and flexibility, such as high-quality paperboard or plastic, are ideal for achieving crisp and detailed embossing effects.

3. Heat and Pressure Application

During the embossing process, the material is placed between the male and female dies. Heat and pressure are applied to press the design into the material, creating a raised or recessed effect. The temperature and pressure settings are adjusted based on the material type and design complexity.

4. Finishing Touches

After embossing, additional finishing techniques such as foil stamping or spot UV coating can be applied to further enhance the design. These techniques add color, texture, or gloss to the embossed areas, making them stand out even more.

What are the Uses of Embossing in Packaging?

Embossing is widely used across various industries to create packaging that is both functional and aesthetically appealing. Below are some of the most common applications:

1. Branding and Logo Enhancement

Embossing is often used to highlight brand logos, names, or taglines on packaging. This not only reinforces brand identity but also creates a premium look and feel that resonates with consumers.

2. Luxury and Premium Packaging

High-end products such as cosmetics, perfumes, and gourmet foods often feature embossed packaging to convey a sense of luxury and exclusivity. The tactile experience of embossed designs adds to the overall perception of quality.

3. Product Differentiation

In competitive markets, embossing helps products stand out on retail shelves. Unique embossed patterns or textures can attract consumer attention and influence purchasing decisions.

4. Special Editions and Gift Packaging

Embossing is frequently used for limited-edition products or gift packaging to create a memorable unboxing experience. The technique adds a touch of sophistication and makes the packaging more collectible.

What Challenges Do Manufacturers Face When Using Embossing in Packaging?

Embossing offers significant benefits for packaging design but also introduces complexities that manufacturers must address. Understanding these challenges is crucial for optimizing the embossing process while maintaining cost-effectiveness and product quality:

1. Cost Implications

The production of custom dies for embossing, along with the additional processing steps, can substantially increase manufacturing costs. This often limits embossing to high-value or premium products, where the investment aligns with brand positioning.

2. Material Limitations

Not all packaging materials are suitable for embossing. Thin or fragile substrates may tear or lose structural integrity under the applied heat and pressure, reducing the range of materials that can be effectively used.

3. Design Complexity

Intricate designs require advanced die-making techniques and precise calibration during the embossing process. This can result in longer production times and increased difficulty in achieving consistent results across large batches.

4. Environmental Considerations

Some embossing materials and finishes may conflict with sustainable packaging practices. Manufacturers often need to balance aesthetic and tactile appeal with the growing demand for eco-friendly solutions.

While embossing offers numerous benefits, it also presents certain challenges that manufacturers must address to achieve optimal results:

What are the Future Trends in Embossing for Packaging?

Embossing in packaging is continually evolving to meet changing consumer preferences and industry demands. Below are some of the key trends that are shaping the future of this technique:

- Sustainable Materials: The use of eco-friendly materials and processes in embossing is gaining traction as brands prioritize sustainability.

- Digital Embossing: Advances in digital printing technology are enabling more precise and cost-effective embossing solutions.

- Interactive Designs: Embossed packaging with QR codes or augmented reality features is emerging as a way to engage consumers and provide additional information.

- Personalization: Custom embossing for individual consumers or small batches is becoming more feasible with advancements in die-making and printing technologies.

These future trends demonstrate how embossing is adapting to both technological advancements and the growing emphasis on sustainability and consumer interaction, ensuring its continued relevance in custom packaging design.