Die cutting is a precision manufacturing technique that uses custom-shaped dies to cut materials like cardboard, paperboard, plastics, and corrugated sheets, playing a crucial role in creating customized packaging. The process can be executed through flatbed die cutting for intricate, low-volume designs, rotary die cutting for high-speed bulk production, and digital die cutting for computer-controlled, tool-free cutting ideal for prototypes. The typical die-cutting workflow includes designing the die, selecting the right material, cutting it, and applying finishing touches such as creases, embossing, or perforations. Tools include metal dies, manual and automated die-cutting machines, and digital systems for precision and flexibility. Key benefits in packaging include high accuracy, extensive customization, efficiency, and support for sustainability through reduced waste and the use of eco-friendly materials. Its applications span industries such as retail, pharmaceuticals, food and beverage, and electronics.

What is Die Cutting?

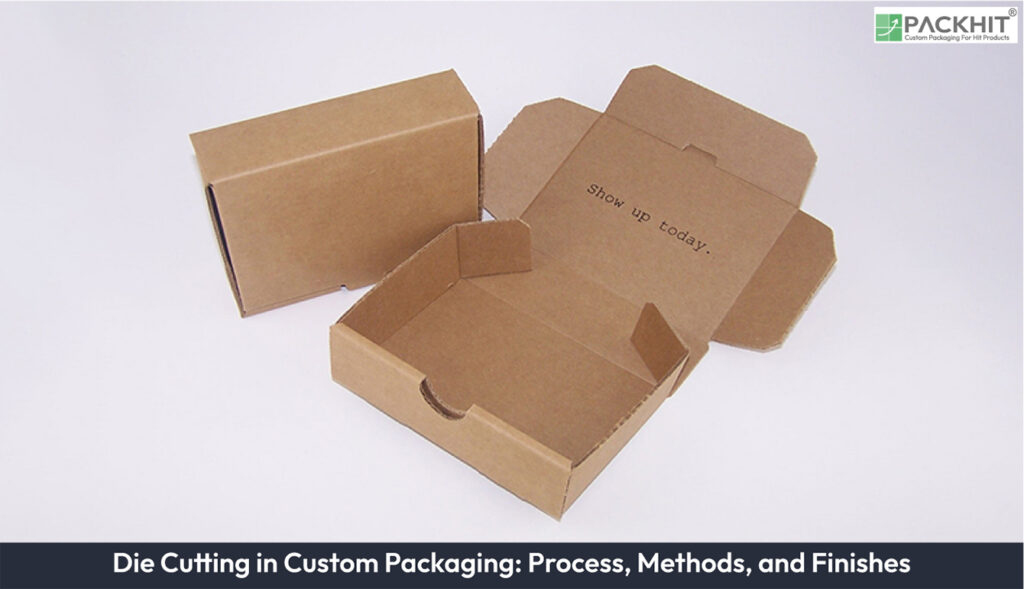

Die cutting is a precise cutting technique that uses specialized tools, known as dies, to shape materials such as cardboard, paperboard, corrugated materials, and plastics. The process is integral to the packaging industry, enabling the creation of tailored designs that meet specific product requirements.

What are the Types of Die Cutting Techniques?

Die cutting encompasses various types, such as flatbed die cutting or rotary die cutting, each suited to specific applications and material types.

The three most common types of die cutting are mentioned below:

1. Flatbed Die Cutting

Flatbed die cutting uses a flat die and a press to cut materials. It is ideal for creating intricate designs and is commonly used for small production runs.

2. Rotary Die Cutting

Rotary die cutting employs a cylindrical die that rotates to cut materials. This method is highly efficient and suitable for large-scale production.

3. Digital Die Cutting

Digital die cutting uses computer-controlled machines to cut materials without the need for physical dies. It is perfect for prototypes and short runs, offering high precision and flexibility.

What is the Process of Die Cutting?

The die cutting process is a versatile manufacturing technique used to shape and cut materials into specific designs with precision. Depending on the scale and complexity of production, it can be conducted manually or automated using advanced machinery.

Below is a detailed step-by-step overview of the die-cutting process:

- Design Creation: The process begins with designing a custom die that matches the required shape, size, and functional features of the packaging material. This step often involves CAD software to ensure accuracy and feasibility.

- Material Selection: Selecting the appropriate material is critical to achieving desired results. Commonly used materials include cardboard, paperboard, corrugated sheets, and plastics, each chosen based on durability, flexibility, and aesthetic requirements.

- Die Cutting: The die is applied to the material either manually or through automated die cutting machines. The material is pressed or stamped with the die to achieve precise cuts and shapes that match the design specifications.

- Finishing: This final step incorporates enhancements such as creases, perforations, embossed designs, or decorative cuts to improve functionality, branding, and visual appeal. Finishing ensures the packaging meets both practical and aesthetic criteria.

Tools Used in Die Cutting:

Die cutting relies on specialized tools and machinery that are listed below:

- Metal Dies: Custom-designed tools used to cut specific shapes.

- Die Cutting Machines: Automated or manual machines that apply pressure to the die for cutting.

- Digital Die Cutting Machines: Advanced machines that use computer-aided designs for precision cutting.

What are the Benefits of Die Cutting in Packaging?

Die cutting offers numerous advantages in the packaging industry, making it a preferred choice for manufacturers seeking custom solutions.

The benefits of die cutting in packaging include the following:

Precision and Accuracy

Die cutting ensures precise, accurate, and consistent designs, enabling the creation of packaging that fits products perfectly. Typical tolerances range from ±0.3 mm to ±1.0 mm, depending on substrate thickness and machine type. Examples of precise outcomes include clean die-cut windows, exact locking tab engagement, and tight print to dieline registration.

Customization

The customization process allows tailored packaging solutions, including unique shapes, sizes, and finishes that align with brand identity. Design teams add features such as display windows, perforated tear strips, and integrated trays to match merchandising and protection needs. Examples of tailored packaging solutions include display trays, gift boxes, and mailer cartons made from coated or uncoated boards.

Efficiency

Die cutting improves production speed and reduces material waste, making it a cost-effective option for large-scale manufacturing. Production rates vary by method and machine, from several hundred to tens of thousands of units per hour, depending on complexity. Nesting layouts and repeatable die registration reduce scrap and cut per-unit labor time.

Sustainability

By optimizing material usage and enabling the use of eco-friendly materials, die cutting supports sustainable packaging initiatives. Examples of eco-friendly materials include recycled paperboard, kraft fiberboard, and compostable films. Precise cutting reduces offcut volume and supports mono-material constructions that improve recyclability in common collection streams.

Applications of Die Cutting in Different Industries

Die cutting is versatile and finds applications across various industries. Below are some notable examples:

Retail Industry

Retail brands such as clothing labels, food chains, and cosmetics lines use die cutting to create promotional displays and personalized packaging that improve unboxing presentation and increase shelf visibility. Designs include display windows, hang tabs, and shaped sleeves that expose product details and support impulse buys. Digital die cutting lets teams run short batches for seasonal promos and cut material efficiently to reduce offcut waste.

Pharmaceutical Industry

Pharmaceutical suppliers such as drug manufacturers, compounding pharmacies, and over-the-counter producers use die cutting to produce tamper-evident folding cartons that meet regulatory labeling and safety needs. Die cuts add perforated seals, tear strips, and precise flaps for child-resistant features and controlled access. Precise dieline registration keeps barcodes, lot numbers, and printed directions clear after folding.

Food and Beverage Industry

Food and beverage companies such as bakeries, beverage makers, and snack producers use die-cut boxes to protect products and present them cleanly on shelves. Die cutting creates vents, built-in handles, and clear windows that show the product without extra wrapping. Materials are chosen for moisture resistance and food contact compliance to keep contents safe during storage and transport.

Electronics Industry

Electronics manufacturers such as phone makers, accessory brands, and component suppliers use die cutting to create fitted inserts and cartons that prevent movement and absorb shock. Die-cut foam and corrugated inserts secure screens, cables, and small parts and stop connectors from rubbing. Cuts match product geometry so assembly and packing run faster on the production line.